- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Buttweld Seamless Steel Pipe Elbow

2. Materials: Carbon steel / Alloy steel / Stainless steel, surface treated with sandblasting + anti-rust oil / water-based eco-friendly paint / epoxy coating

3. Custom sizes supported and special materials available

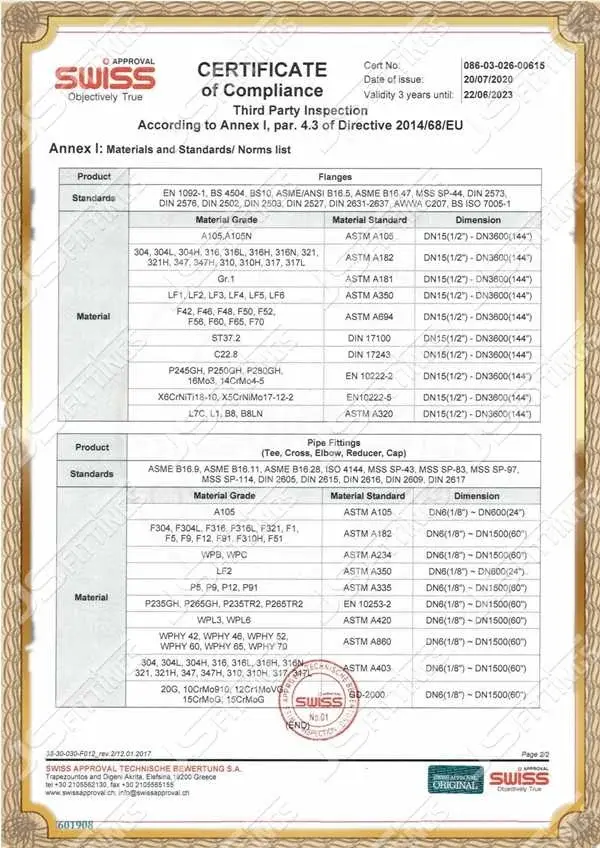

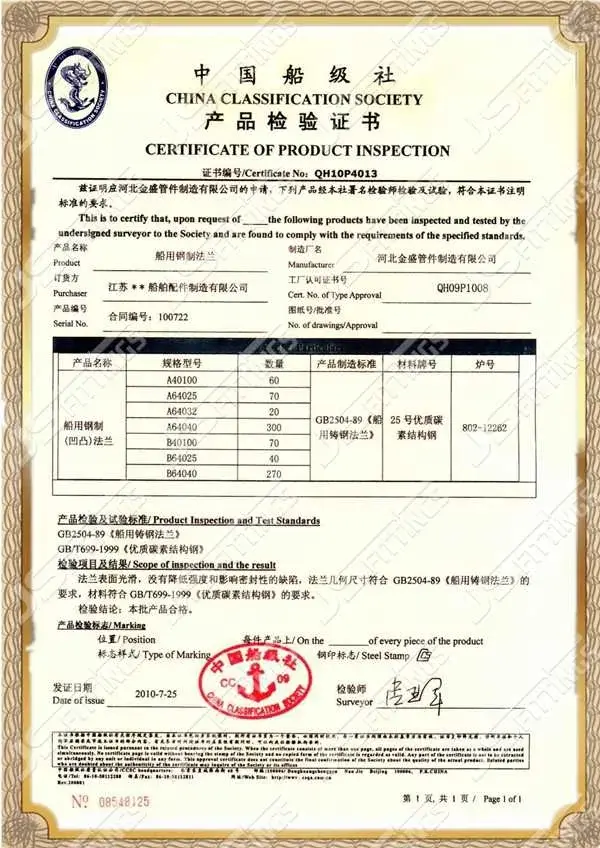

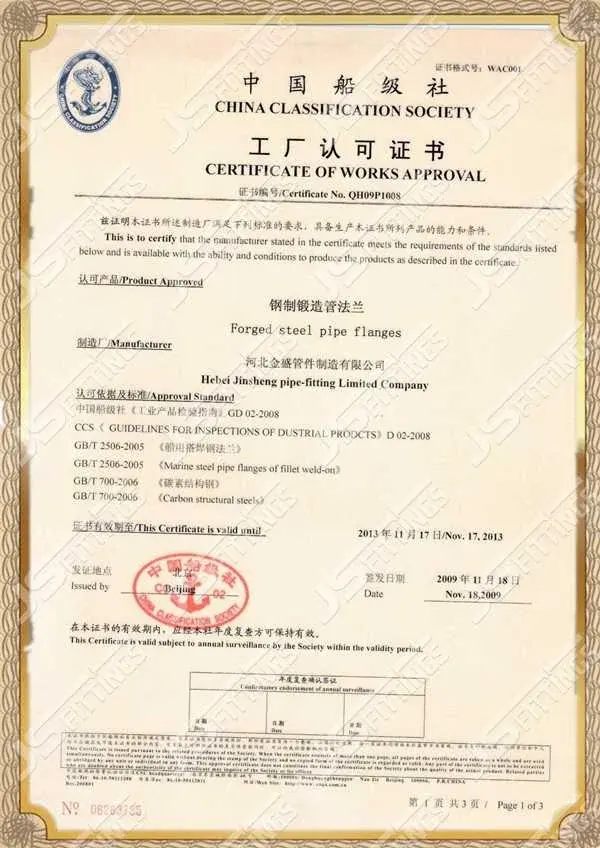

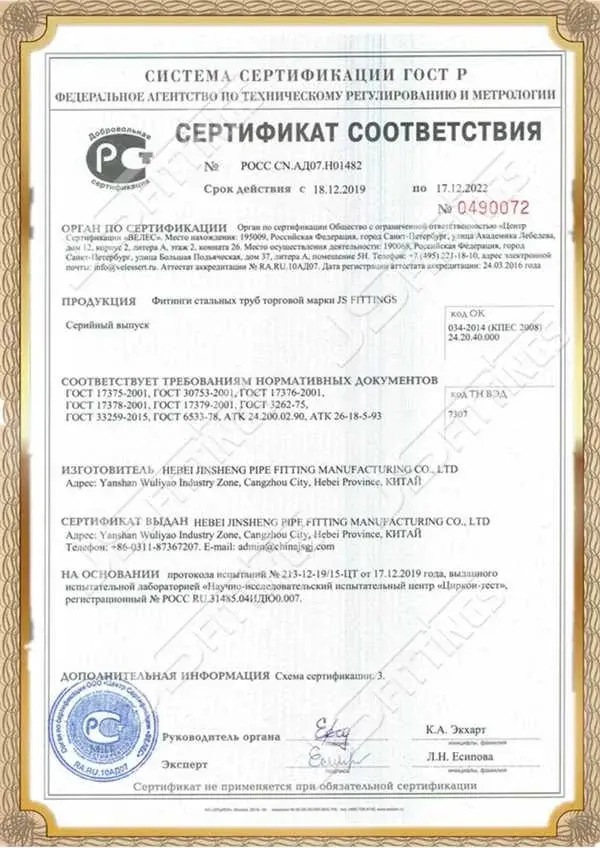

4. Full product range certified by CE/PED 2014/68/EU, ISO 9001, GOST-R, with complete technical documentation provided

5. Cooperate with NIOC, ADNOC, Pand ETROBRAS

Butt Weld Elbow – Adjusting the Flow Direction Of Fluid In Piping Systems

Butt weld elbow is a commonly used fitting in piping systems. It is used to connect two pipes with the same or different nominal diameters, and to make the pipe turn to a certain direction of 45 degrees or 90 degrees.

Butt weld elbow is a steel elbow formed by hot pressing or forging. Its connection form is to directly weld the elbow and steel pipe. Butt welded elbows are mainly used for elbow with higher pressure and temperature than other connection types (socket welded elbow or threaded pipe elbow)

Butt weld Elbow Types

180° butt weld elbow

180 Degree steel elbow helps change direction at 180 degrees, since it usually results in low pressure. Its application is limited to minimal deposition and low turbulence system.

- There are 180° short radius elbows and 180° long radius elbows. Long radius elbows provide smaller flow resistance and pressure loss, and are suitable for general piping systems. Short radius elbows are suitable for limited space or situations that require faster changes in flow direction.

- They are commonly used in situations where there is a need for a significant change in direction, causing the fluid to flow in the opposite direction.

- It is connected to the pipe by welding. It has high strength and sealing performance, and can withstand high pressure and temperature.

- Made of materials such as stainless steel, duplex steel, or special alloy steel, it has corrosion resistance and can resist corrosion from oxidizing agents, acids, alkalis, salt solutions, and other corrosive media.

90° butt weld elbow

90 degree steel pipe elbow functioned to change fluid direction by 90 degree, so also named as vertical elbow. It is the common degree in all the pipeline systems and used most in all different degree of elbows. (As it is convenient to suit to steel construction and structural.)

Long radius 90 degree elbow

LR 90 degree steel pipe elbow are installed between different lengths pipe or tubing. It helps to change direction at 90 degree, and is commonly used to connect hoses to pumps, deck drains and valve.

Short radius 90 degree elbow

SR 90 degree elbow is the same as the pipe elbow mentioned above, but the diameter is shorter. Therefore, this kind of steel elbow is often used when space is not.

45 Degree Steel Pipe Elbow

45 degree elbow is second common use after 90 degree elbow.

45 degree elbow of long radius

The pipe elbow is mounted between two pipes so that the fluid direction can be changed to 45 degrees. Compared to 90 degree elbow, 45 degree elbow produces less friction, and with the lower pressure.

45 degree elbow of short radius

SR Elbow in 45 degree is usually attached to copper, plastic, steel, cast iron and lead, and can also be connected to stainless and rubber fixtures. It is widely used in Chemical, food, water supply facilities, electronic industry, chemical pipelines, horticulture, agriculture production, solar equipment pipelines, air conditioning pipeline and other fields.

What is the Elbow Radius?

The elbow radius mean curvature radius. If the radius is the same as the pipe diameter, it is called a short radius elbow, also called an SR elbow, normally for low-pressure and low-speed pipelines.

If the radius is larger than the pipe diameter, R ≥ 1.5 Diameter, then we call it a long radius elbow (LR Elbow), applied for high-pressure and high-flow-rate pipelines.

Material & Standard

Carbon Steel Buttweld Elbow

Material in carbon steel, referred standards as:

- ASTM 234 WPB and WPC

- ASTM A420 WPL6

- MSS-SP-75 WPHY 42, 46, 52, 56, 60, 65 and 70

Stainless Steel Buttweld Pipe Elbow

Material in stainless steel, referred to standards as:

- ASTM A403 WP 304/304L, 316/316L

- ASTM A270

Key Features

Our products stand out for their:

- Seamless construction: Eliminates weak points for enhanced pressure resistance

- Precision manufacturing: Ensures perfect fit and alignment in your piping systems

- Corrosion resistance: Specially treated materials for harsh environments

- High temperature tolerance: Ideal for extreme operating conditions

- Compliance with international standards: ASTM, ASME, and API specifications

Surface Treatment

We offer various surface finishes to meet your project needs:

- Pickled and passivated

- Sand blasted and painted

- Galvanized

- Special coatings for enhanced corrosion protection

Applications

Our Buttweld Seamless Steel Pipe Elbows excel in diverse industries:

- Oil & Gas: Exploration, refining, and transportation pipelines

- Chemical Processing: Corrosive fluid handling systems

- Power Generation: High-pressure steam and coolant lines

- Shipbuilding: Marine-grade piping for offshore platforms and vessels

- Construction: HVAC and water supply networks

- Heavy Machinery: Hydraulic systems and equipment manufacturing

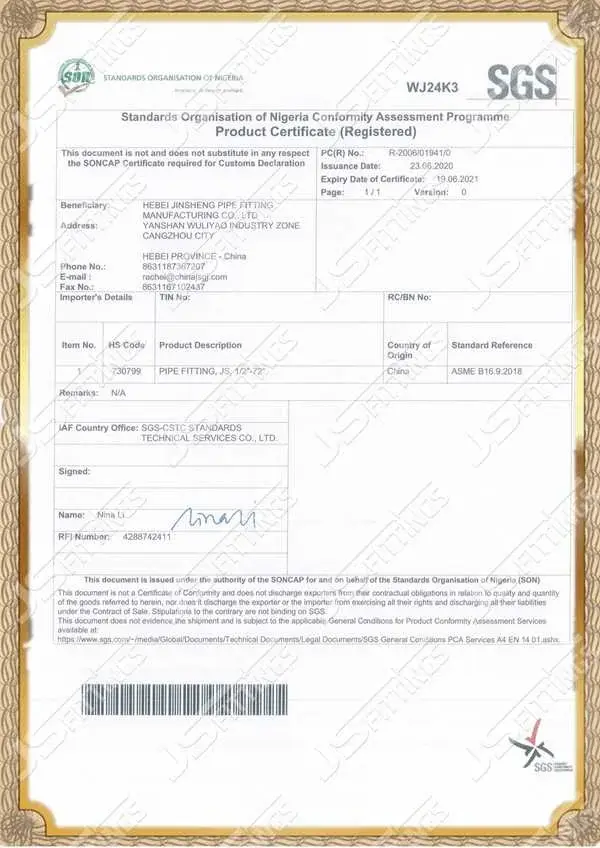

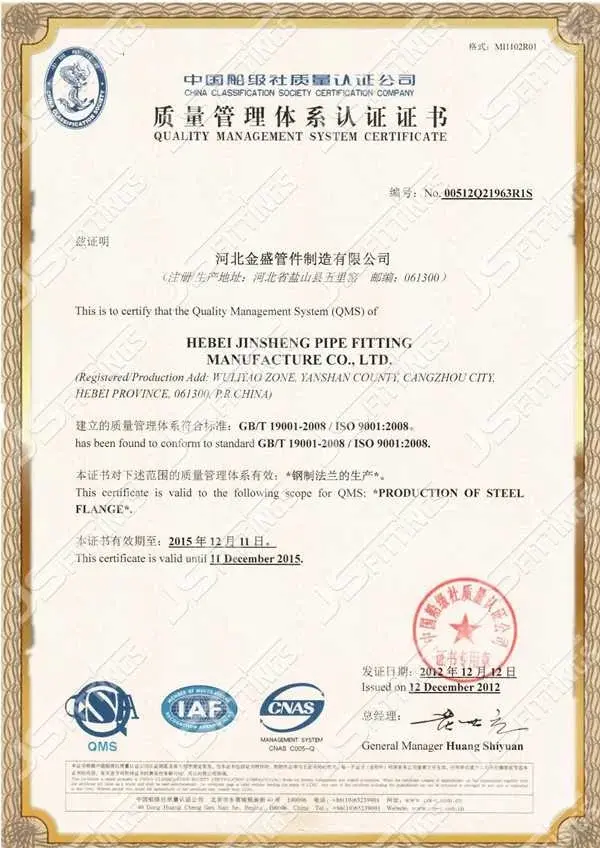

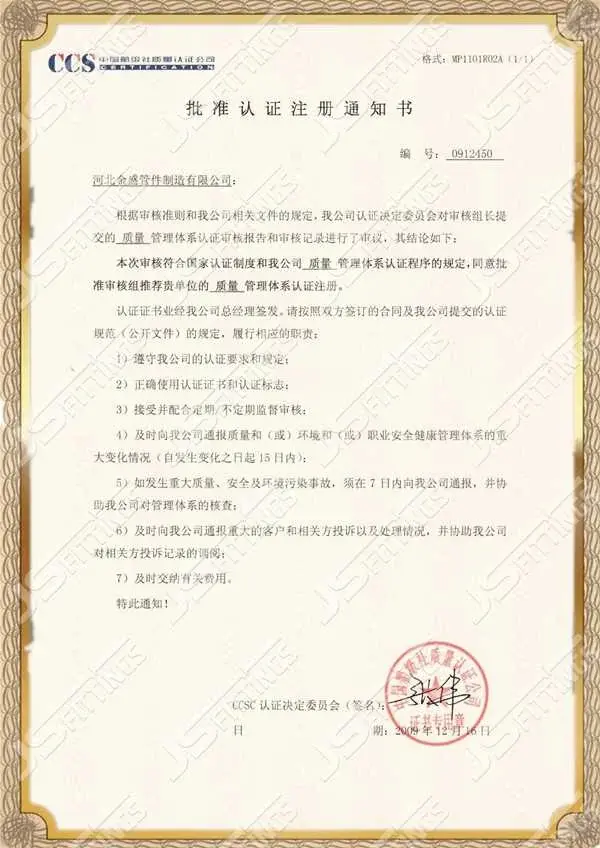

Quality Certificates

Trust in our internationally recognized certifications:

- ISO 9001:2015 Quality Management System

- CE marking for European market compliance

- API 5L and API 6A for oil & gas industry standards

- PED (Pressure Equipment Directive) certification

- NORSOK approval for offshore applications

Why choose JSFITTINGS as your buttweld pipe fitting Factory?

Our butt weld fittings are suitable for Hot and Cold water, Oil, Gas, Nuclear power and chemical processing lines.

We have cooperated with many national oil companies such as ADNOC, PETROBRAS, and CNPC, etc.

JSFITTINGS is a butt weld pipe fittings manufacturer that offers the full range of fittings of ASME B16.9, ASME B16.28, ASME B16.49, GOST 17375, GOST 30753-2001, GOST 17376, GOST 17378, GOST 17379, EN 10253 butt weld pipe elbow, pipe reducer, pipe tee, pipe cross, pipe bends, and pipe caps. JSFITTINGS' high-quality products have been approved by ISO 9001, GOST-R, and CE.

Customized steel pipe fittings are also available.

Benefits of Butt Weld Fittings

Continuous metal structure increases the strength of the piping system

• Various turning options and easy to weld.

• Butt weld saves more cost than socket weld or threaded.

• Allow thin thickness as SCH 10 or SCH 10S.

• Compatible with different sizes from 1/4 inch to 24 inch and up to 72 inch.

JSFITTINGS supplies buttweld pipe fittings with competitive price and urgent delivery.

Material standard ASTM A234 WPB, WP5, WP9, WP11, WP22. Dimensions up to 48 inch.

FAQ

Q: Where is your factory?

A: The factory of RAYOUNG is in the base of Chinese pipe fittings, Yanshan County, Cangzhou City, Hebei Province. contact us to get the visit brochure.

Q: What is your annual production?

A: The output is 1000 tons/month, almost an export of 35-40 containers per month, annual output is more than 10000 tons.

Q: How can I get your price list?

A: The real price is based on the size, thickness, surface treatment, material, standard, quantity, and destination. If you don't have a purchase plan, we can supply you with a FOB price based on 1 container for reference.

Q: Do you have distributors in my country?

A: We have stable distributors in Russia, Thailand, the UAE, Nigeria, South Africa, Iran, and other countries. If you can't import by yourself, we will be glad to introduce you to our customers.

Q: What is the warranty time of your products?

A: The warranty period for regular carbon steel products is 1 year, and the normal use time is over 3 years. The warranty period for special products can reach more than 5 years.

Q: What is the minimum order quantity (MOQ) for your elbows?

A: We offer flexible MOQs to accommodate both small and large projects. Contact our sales team for details.

Q: Can you provide custom products?

A: Yes, we specialize in creating custom solutions. Our engineering team will work closely with you to meet your exact specifications.

Q: What is the typical lead time for standard orders?

A: Lead times vary based on material and quantity, but we strive for 2-4 weeks for most standard orders. Rush options are available.

Q: Do you provide material test reports (MTRs) with your products?

A: Absolutely. We provide comprehensive MTRs and all necessary documentation for full product traceability.

Q: How do you ensure consistent quality across large orders?

A: Our advanced automated production lines, coupled with rigorous quality control measures at every stage, guarantee uniform quality for even the largest bulk orders.

Contact Us

Ready to elevate your piping systems with our superior Buttweld Seamless Steel Pipe Elbows? Our team of experts is standing by to assist you with product selection, technical support, and competitive quotes.

Email: admin@chinajsgj.com

Tel/WhatsApp: +8618003119682

JSFITTINGS Steel Pipe Fitting Engineering and Supply Company welcomes Active engineering trading and stockists.

Learn about our latest products and discounts through SMS or email