- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Seamless Butt Weld steel pipe fitting

2. Materials: Carbon steel / Alloy steel / Stainless steel, surface treated with sandblasting + anti-rust oil / water-based eco-friendly paint / epoxy coating

3. Custom sizes supported (e.g., reducing tees, large-diameter 90° elbows) and special materials available

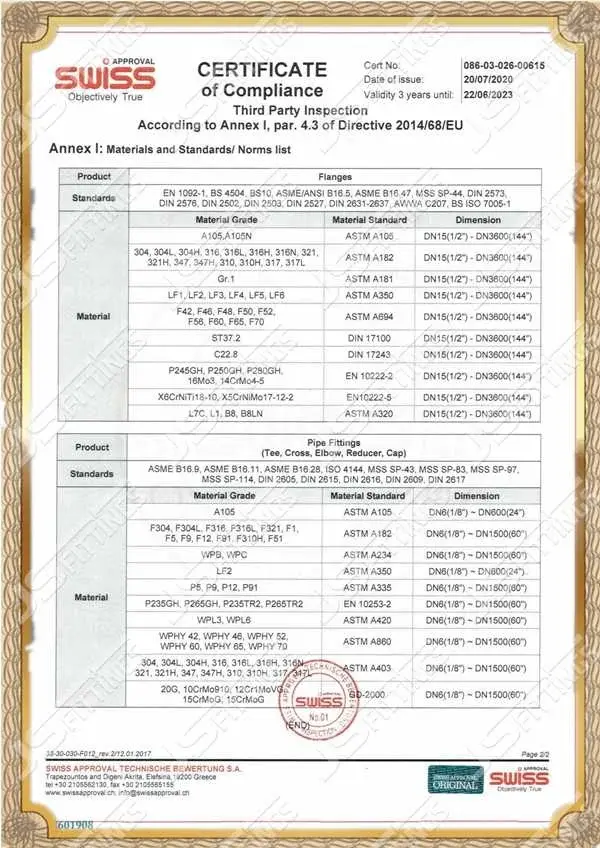

4. Full product range certified by CE/PED 2014/68/EU, ISO 9001, GOST-R, with complete technical documentation provided

5. Approved by NIOC, ADNOC, PETROBRAS

Seamless butt weld steel pipe fittings are components used to connect pipes in a piping system where the ends of the pipes and fittings are welded together, creating a strong, leak-proof joint. These fittings are available in both seamless and welded versions, with seamless fittings generally preferred for higher pressure or temperature applications due to their lack of weld seams.

Key characteristics of seamless butt weld fittings:

Seamless Construction:

These fittings are formed from a single piece of metal, typically by piercing a heated billet of steel, rather than being welded together from separate pieces.

Butt Welding:

The fittings are welded directly to the ends of the pipes, creating a continuous, leak-tight connection.

Material Options:

Seamless butt weld fittings are available in various materials, including carbon steel, stainless steel, and other alloys.

Wide Range of Applications:

They are used in diverse industries such as petrochemical, oil and gas, water treatment, and more.

Seamless vs. Welded Butt Weld Fittings:

Seamless:

Generally considered stronger and more reliable, especially in high-pressure and high-temperature applications, due to the absence of weld seams.

Welded:

Typically used for larger diameter pipes and may be more cost-effective, but the weld seam can be a potential weak point.

Seamless Butt Weld Steel Pipe Fittings: Premium Quality for Industrial Applications

Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd. is a leading manufacturer and supplier of high-quality Seamless Butt Weld steel pipe fittings. With over 39 years of expertise, our 35,000 m² state-of-the-art facility produces 30,000 tons of ASTM/EN-compliant fittings annually. Our ISO 9001, CE, and PETROBRAS certifications ensure uncompromising quality for oil & gas, shipbuilding, and construction sectors. Trust JS FITTING for durable, reliable products that meet your industrial needs.

Key Features

- Premium Quality: Our Seamless Butt Weld fittings are manufactured using advanced technology, ensuring superior strength and durability.

- Precise Dimensions: Each fitting is crafted to exact specifications, guaranteeing perfect alignment and leak-free connections.

- Corrosion Resistance: High-grade materials and surface treatments provide excellent resistance to corrosion and chemical attack.

- Pressure Ratings: Engineered to withstand high-pressure applications in demanding industrial environments.

- Compliance: All fittings meet or exceed industry standards, including ASTM, ASME, and MSS-SP specifications.

Product Types

We offer a comprehensive range of the products to suit various piping configurations:

- Elbows (45°, 90°, and 180°)

- Tees (equal and reducing)

- Reducers (concentric and eccentric)

- Caps

- Stub ends

- Weldolets and sockolets

Materials & Grades

Our Seamless Butt Weld fittings are available in a variety of materials to meet your specific application requirements:

- Carbon Steel: ASTM A234 WPB, WPC

- Alloy Steel: ASTM A234 WP1, WP5, WP9, WP11, WP22, WP91

- Stainless Steel: ASTM A403 WP304/L, WP316/L, WP321, WP347

- Duplex and Super Duplex: ASTM A815 UNS S31803, S32750, S32760

Surface Treatment

To enhance performance and longevity, we offer various surface treatment options:

- Pickling and passivation

- Sandblasting

- Anti-corrosion coatings

- Galvanization

- Custom treatments upon request

Applications

Our Seamless Butt Weld steel pipe fittings are widely used in critical industries, including:

- Oil and gas exploration and refining

- Petrochemical plants

- Power generation facilities

- Chemical processing

- Shipbuilding and marine applications

- Water treatment and distribution systems

- HVAC systems in large-scale construction projects

Packaging & Delivery

We understand the importance of protecting your investment during transit. Our packaging options include:

- Wooden cases

- Pallets

- Bundles with protective wrapping

- Custom packaging solutions for specific requirements

Our dedicated logistics network ensures timely global deliveries for bulk orders, with flexible shipping options to meet your project timelines.

Quality Control

At JS FITTING, quality is our top priority. Our rigorous quality control process includes:

- Raw material inspection and testing

- In-process quality checks at each production stage

- Dimensional and visual inspections

- Non-destructive testing (NDT) as per customer requirements

- Hydrostatic pressure testing

- Final inspection and documentation review

Certificates

Our commitment to quality is backed by internationally recognized certifications:

- ISO 9001:2015 Quality Management System

- CE Marking (Pressure Equipment Directive 2014/68/EU)

- GOST-R for Russian market compliance

- PETROBRAS approval for oil and gas applications

- Material Test Reports (MTR) provided with each shipment

FAQ

Q1: What is the minimum order quantity for the products?

A1: Our minimum order quantity varies depending on the product type and specifications. Please contact our sales team for detailed information.

Q2: Can you provide custom Seamless Butt Weld fittings for non-standard sizes?

A2: Yes, we offer custom fabrication services for special sizes and configurations. Our engineering team can work with you to develop solutions for your unique requirements.

Q3: What is the typical lead time for the product orders?

A3: Lead times vary based on product type, quantity, and current production schedules. Generally, we aim to deliver within 2-4 weeks for standard items and 4-6 weeks for custom orders.

Q4: Do you offer inspection services before shipment?

A4: Yes, we welcome third-party inspections and can arrange for pre-shipment inspections upon request.

Contact Us

Ready to elevate your piping systems with our premium Seamless Butt Weld steel pipe fittings? Contact our expert team today for personalized assistance, quotations, or technical support.

Email: admin@chinajsgj.com

Phone: +8618003119682

Trust Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd. for all your product needs. Our commitment to quality, innovation, and customer satisfaction ensures that you receive the best products for your industrial applications.

Learn about our latest products and discounts through SMS or email