- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

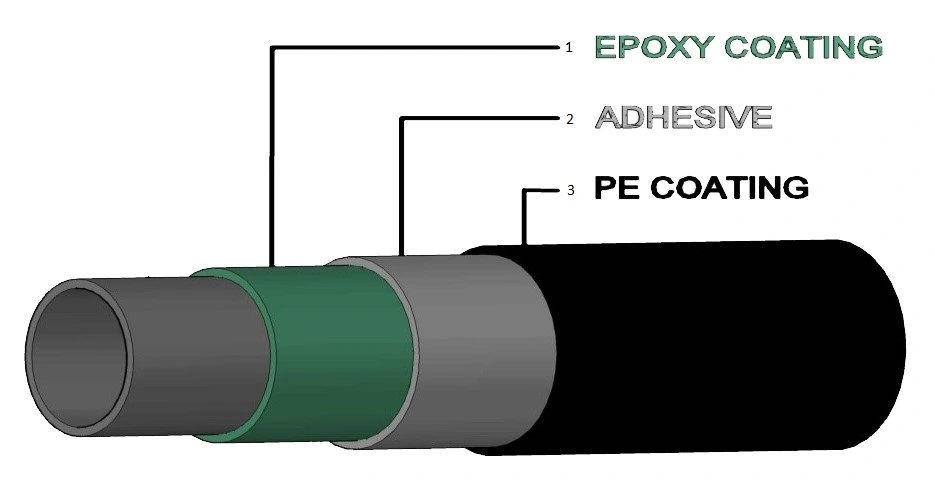

3LPE Coated Steel Pipe

Ends:Square Ends/Plain Ends (straight cut, saw cut, torch cut), Beveled/Threaded Ends

Coating: FBE,Fusion Bonded Epoxy

A three-layer polyethylene coat (3LPE) is a multilayer, anti-corrosive steel pipe coating. The three layers consist of an Epoxy layer, followed by an adhesive layer and a polyethylene layer, as follows:

3LPE Coated Features and Benefits:

⦁ The 3LPE is designed to provide long-term protection to the underground steel pipes, and fights against corrosion caused by soil minerals.

⦁ The layers provide tough and durable protection for pipes.

⦁ Mechanical Protection: The Polyethylene layer protects the pipes during transportation and installation, which consequently reducing costly repairs.

⦁ It also offers strong Chemical resistance that makes 3LPE applicable even in the most aggressive of environments, including all forms of soil. The chemical resistance of this coating prevents corrosion.

⦁ 3LPE can be applied on the outer surface of both black and galvanized steel pipes.

3LPE Coated Pipes Advantages:

1. 3LPE coated pipe can protect the pipe in a severe environment and extend its lifetime to 30-50 years even longer.

2. The 3LPE coated pipe has a favorable thermal insulation property; the thermal losses are just 25% of the traditional pipe.

3. The 3PE coated pipe can be directly laid underground or in the water, even directly in the frozen earth, because of its good anticorrosion property and impact resistance property in low temperatures, without the need to construct a ditch.

Key applications

1. Oil and gas transportation: Widely used for transmitting oil, natural gas, and other fluids, including those in challenging environments like deserts or underwater.

2. Water pipelines: Used in municipal water supply and distribution networks for both clean and raw water transportation, ensuring safety and longevity.

3. Industrial fluid transport: Suitable for transporting a variety of other fluids in industrial settings.

4. Infrastructure projects: Employed for structural and piling applications where durability and corrosion protection are essential.

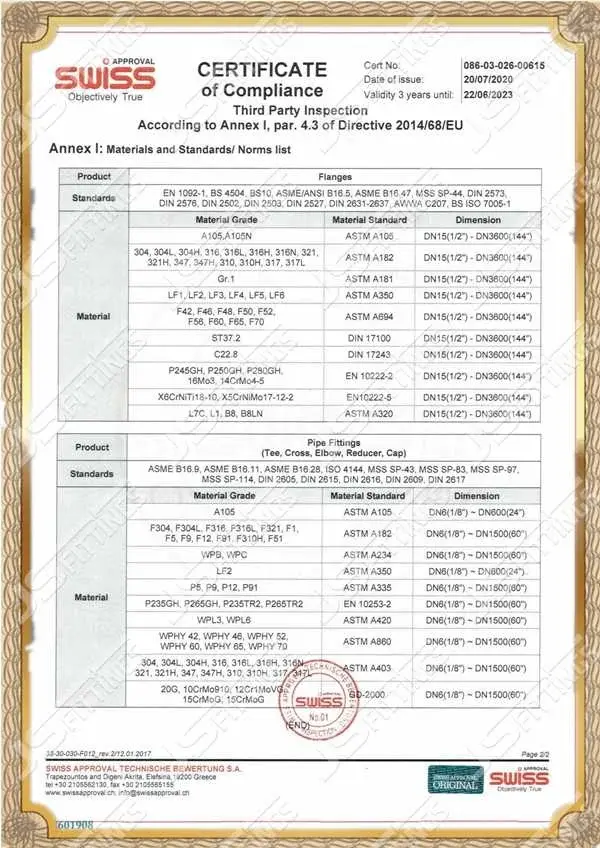

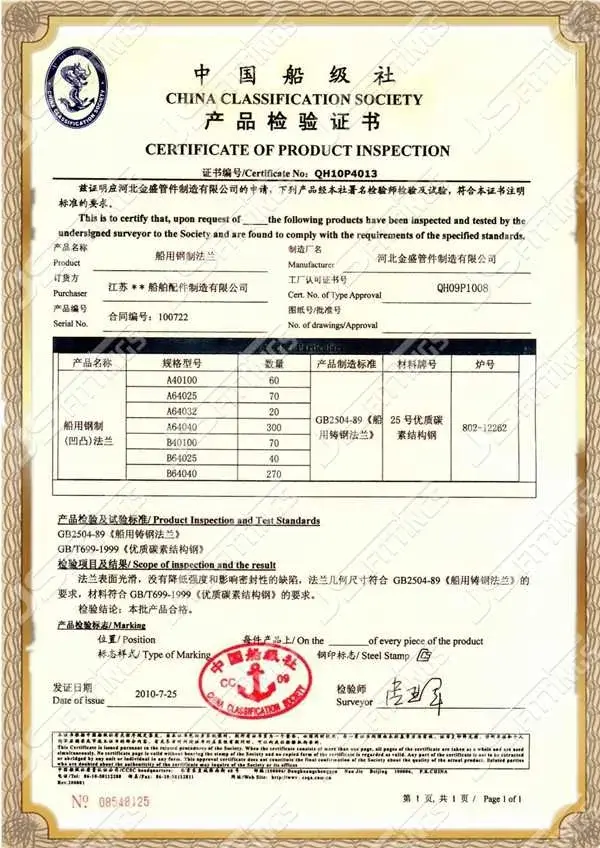

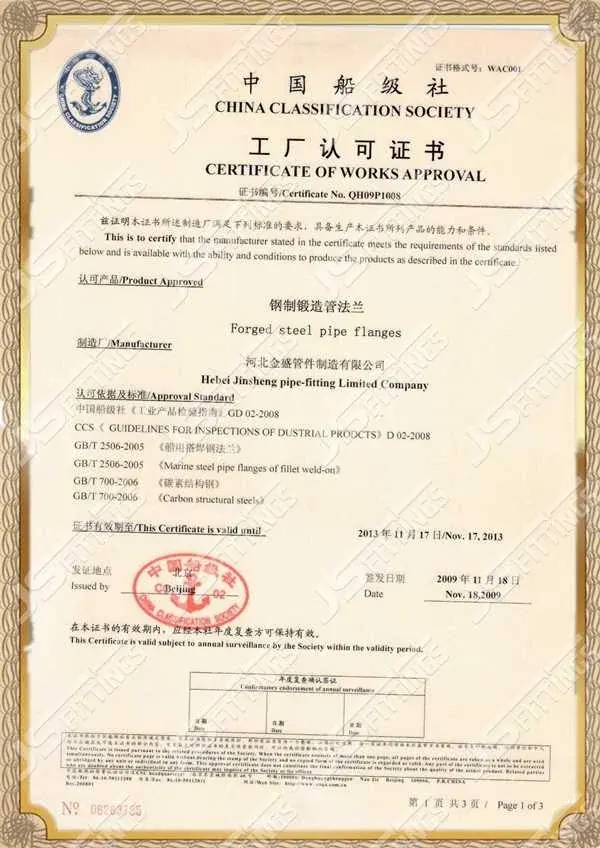

Certificates

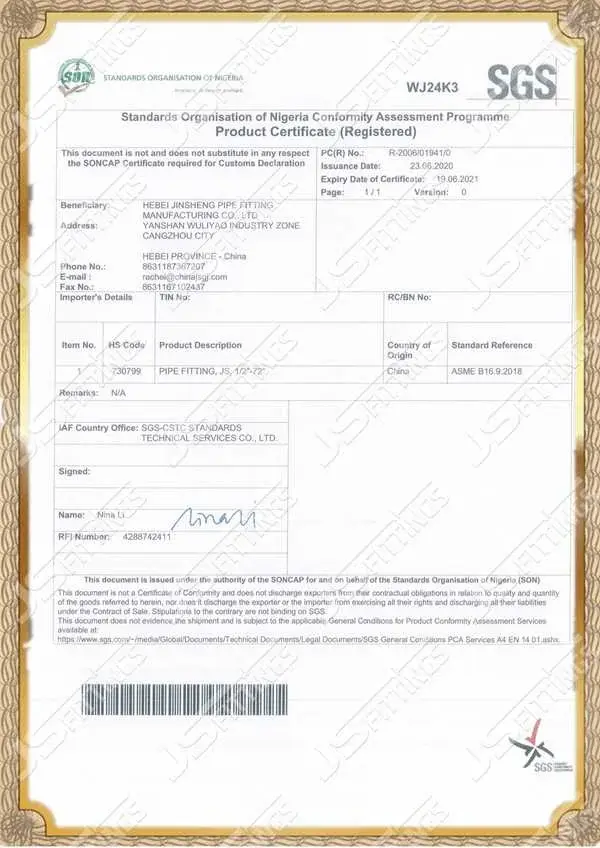

Our commitment to quality is backed by international certifications:

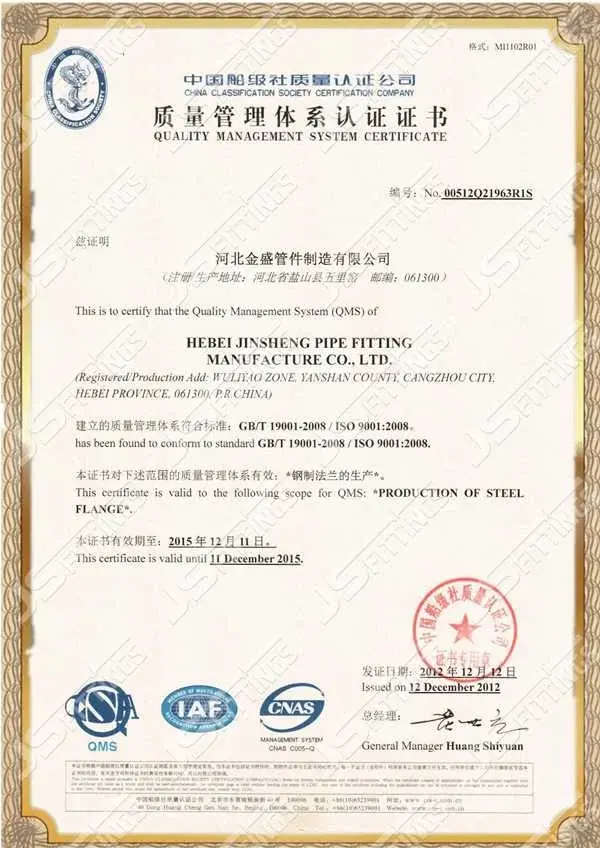

- ISO 9001:2015 Quality Management System

- CE Marking for European market compliance

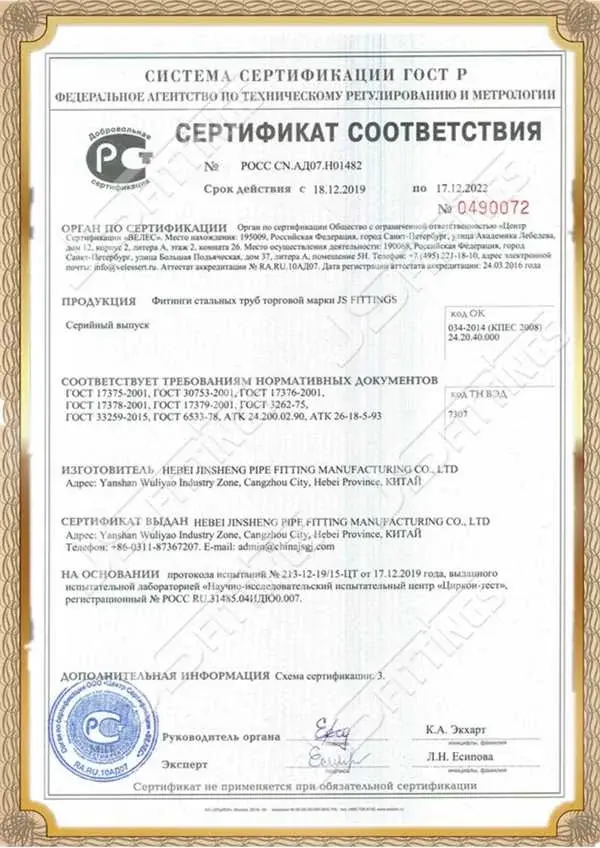

- GOST-R certification for Russian market standards

- API Spec Q1 for oil and gas industry requirements

FAQ

Q1: What is the standard length of your products?

A1: Our standard lengths are 6 meters and 12 meters. However, we can accommodate custom lengths based on your project requirements.

Q2: Can you provide pipes with custom threading or end preparations?

A2: Yes, we offer various end preparations including plain ends, beveled ends, and threaded ends (NPT or BSPT) to suit your specific needs.

Q3: What is the typical lead time for bulk orders?

A3: Lead times vary depending on order volume and complexity. For standard products, we typically aim for 2-4 weeks. Please contact us for a precise estimate based on your requirements.

Q4: Do you offer any corrosion protection options?

A4: Yes, we provide black phosphate coating as standard. For enhanced protection, we can offer hot-dip galvanization or other specialized coatings upon request.

Q5: Can you assist with material selection for my project?

A5: Absolutely. Our experienced technical team can help you choose the most suitable product grade and specifications based on your application and project requirements.

Contact Us

Ready to discuss your 3LPE Coated Steel Pipe needs? Our dedicated team is here to assist you:

Email: admin@chinajsgj.com

Phone: +8618003119682

At Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd, we're committed to delivering high-quality products that meet your exact specifications. With our extensive experience, advanced manufacturing capabilities, and commitment to customer satisfaction, we're your ideal partner for all your industrial piping needs. Contact us today to request a quote or discuss your project requirements!

Learn about our latest products and discounts through SMS or email

_1758005569089.webp)