- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

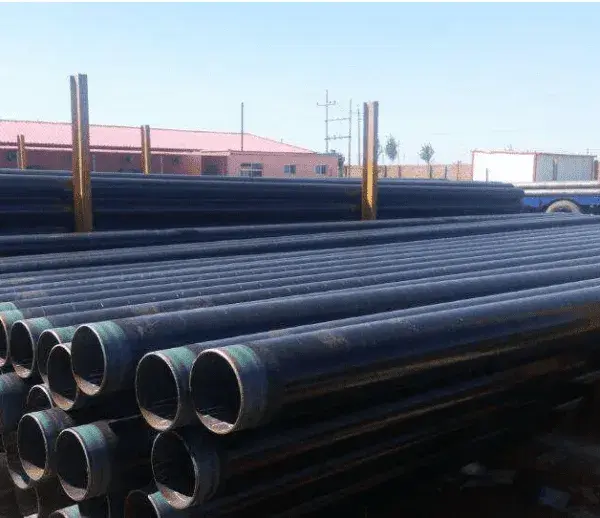

black mild steel pipe

2. Dual-standard certified steel pipes | API 5L + EN 10219 dual compliance assurance

3. Precision Cutting Services | Ready-to-use pipe end treatments

4. Oil and Gas Project Logistics System | Exclusive Shipping Solutions Covering Central Asia/Middle East

Black Mild Steel Pipe - Premium Quality for Industrial Applications

As a leading manufacturer of black mild steel pipe, Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd brings 39 years of expertise to the table. Our state-of-the-art 35,000 m² facility houses advanced production lines, delivering top-quality pipes that meet ASTM and EN standards. With ISO 9001, CE, and PETROBRAS certifications, we ensure uncompromising quality for various industrial sectors.

Key Features

- Durable and versatile for multiple applications

- Compliant with international quality standards

- Cost-effective solution for large-scale projects

- Excellent weldability and formability

- Consistent quality across bulk orders

Product Types

We offer a comprehensive range of the product options to suit your specific needs:

- Seamless pipes

- Welded pipes

- ERW (Electric Resistance Welded) pipes

- Schedule 40 and Schedule 80 pipes

- Custom sizes and lengths available upon request

Materials & Grades

Our products are manufactured using high-quality carbon steel, typically:

- ASTM A53 Grade B

- ASTM A106 Grade B

- API 5L Grade B

- EN 10255 (formerly BS 1387)

These grades offer an excellent balance of strength, ductility, and weldability, making them ideal for various industrial applications.

Surface Treatment

- Black phosphate coating for enhanced corrosion resistance

- Optional hot-dip galvanization for extended durability

- Customizable surface treatments available for specific project requirements

Dimensional Tolerance Checks(Per ASTM A530/API 5L)

|

Parameter |

Tolerance |

Instrument Used |

|

Outer Diameter(OD) |

±1%of nominal OD (or±0.79mm) |

Pi tape/Laser micrometer |

|

Wall Thickness(WT) |

±12.5%(SCH40 and below) |

Ultrasonic thickness gauge(UTG) |

|

Length |

±3mm for random,±6mm for cut-length |

Calibrated tape measure |

|

Straightness |

≤0.2%of total length |

Optical comparator |

|

Bevel Angle (for welding) |

30°-35°(±5°) |

Bevel protractor |

Visual &Surface Inspection

·Defect Identification:

o Lamination- Check for delamination near pipe ends

o Scratches/Dents -Max 5%of WT depth allowed (per ASME B31.3)

o Rust &Mill Scale-Controlled by SSPC-SP6(Commercial Blast Cleaning)

● Method:

o White light inspection(10,000 lux minimum)

o Dye penetrant test(PT)for surface cracks

Applications

Black mild steel pipe is a versatile product widely used across multiple industries:

- Construction: Structural frameworks, scaffolding, and general piping systems

- Oil & Gas: Transportation pipelines and drilling equipment

- Manufacturing: Machinery components and industrial fabrication

- Automotive: Chassis construction and exhaust systems

- Agriculture: Irrigation systems and equipment repair

Packaging & Delivery

- Standard bundle packaging with protective end caps

- Custom packaging options for specific transportation requirements

- Efficient logistics network ensuring timely global deliveries

- Bulk orders accommodated with dedicated shipping solutions

Quality Control

At Hebei Jinsheng, we maintain rigorous quality control measures:

- Raw material inspection and testing

- In-process quality checks at each production stage

- Non-destructive testing (NDT) including ultrasonic and hydrostatic tests

- Dimensional and visual inspections

- Third-party quality audits for enhanced reliability

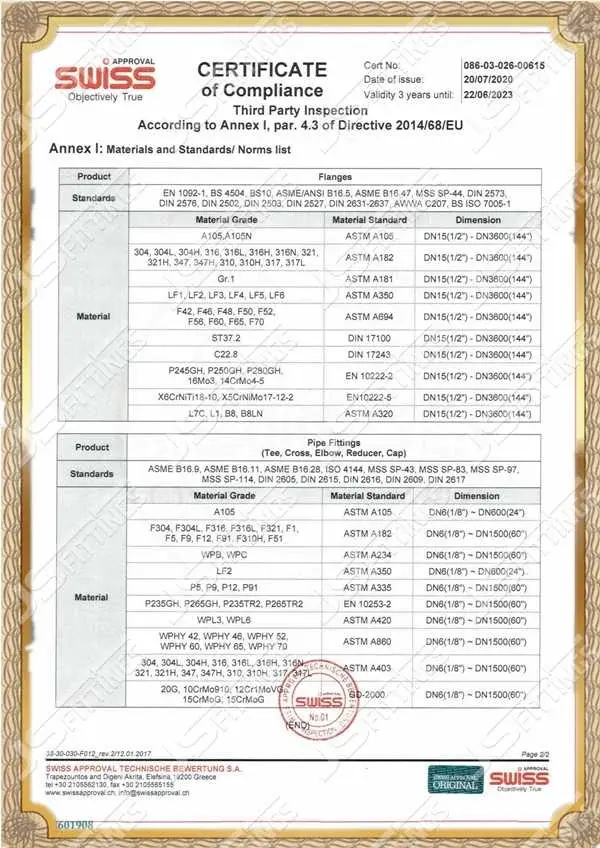

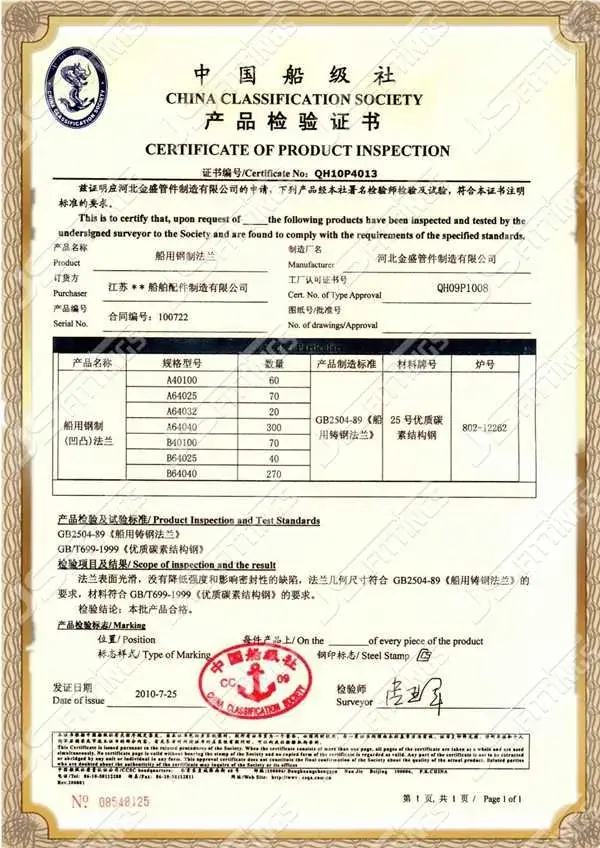

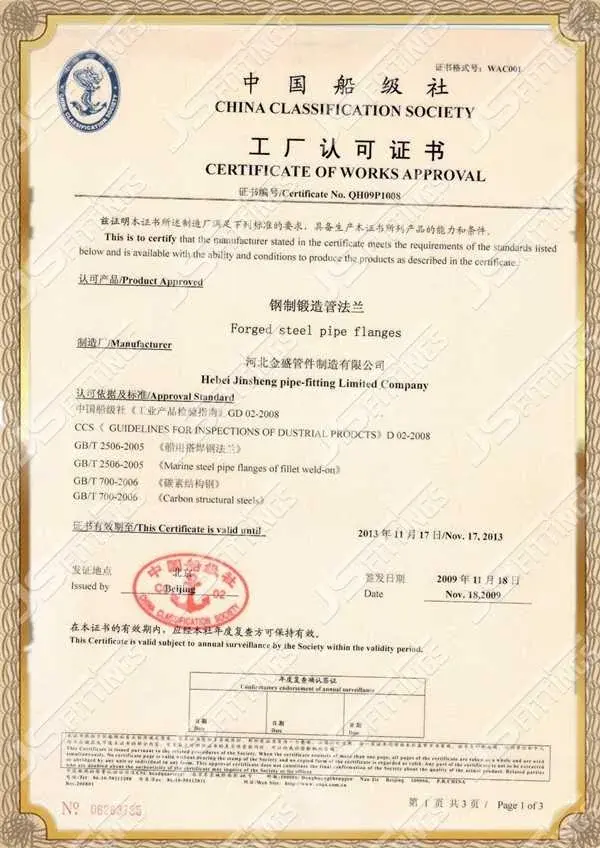

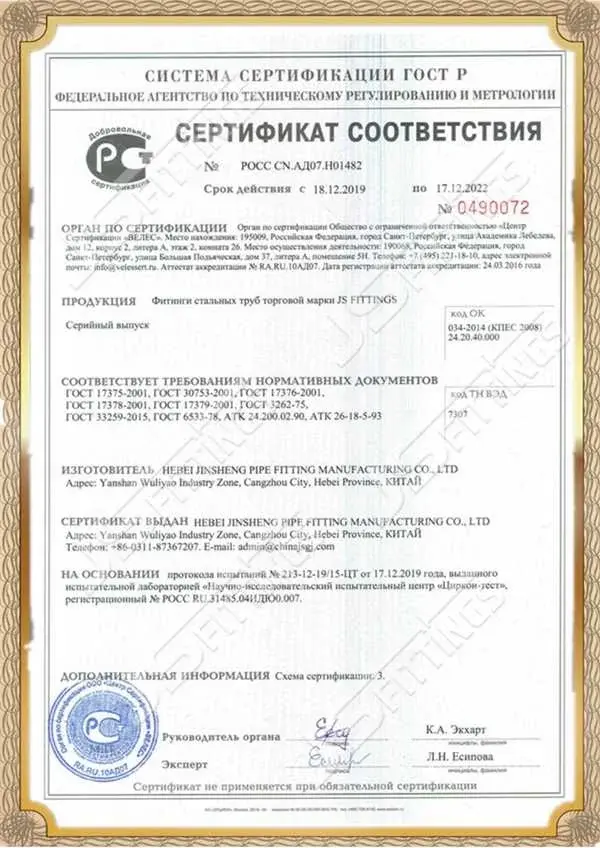

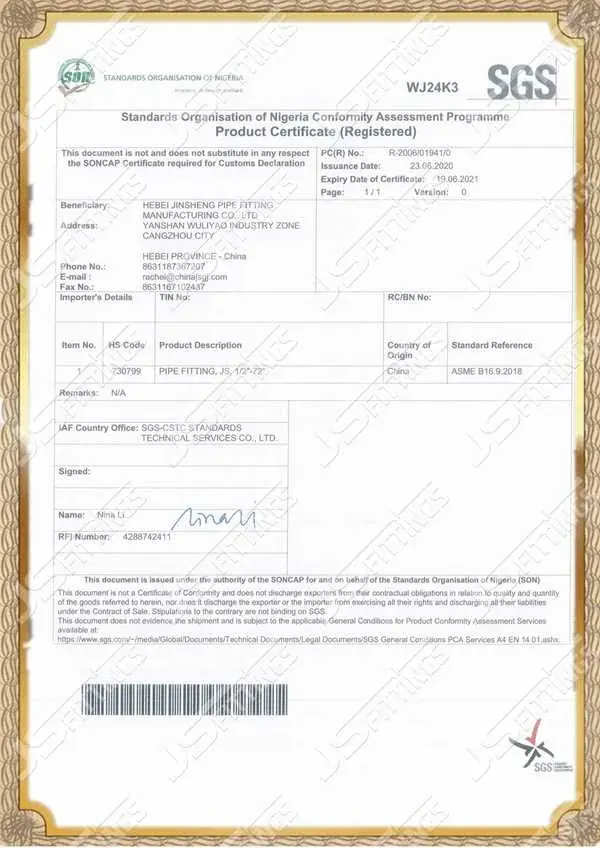

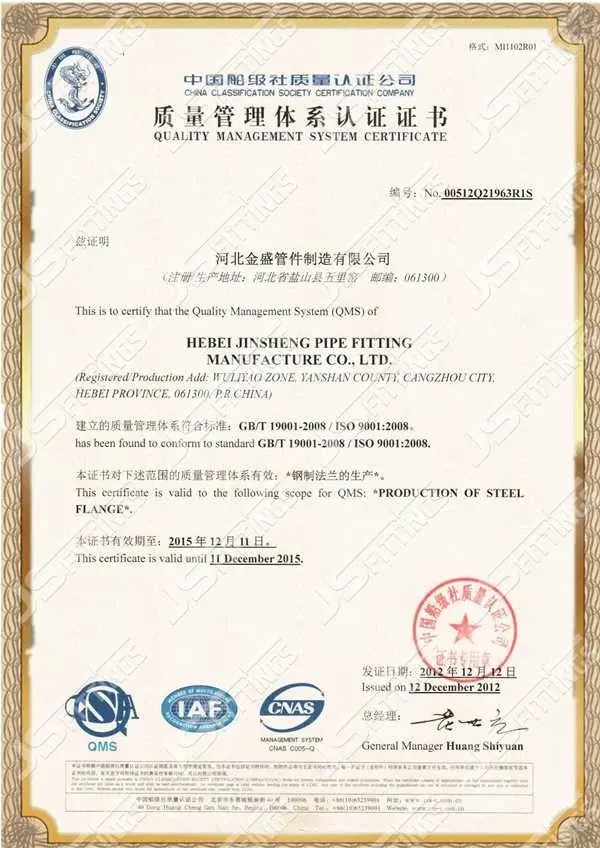

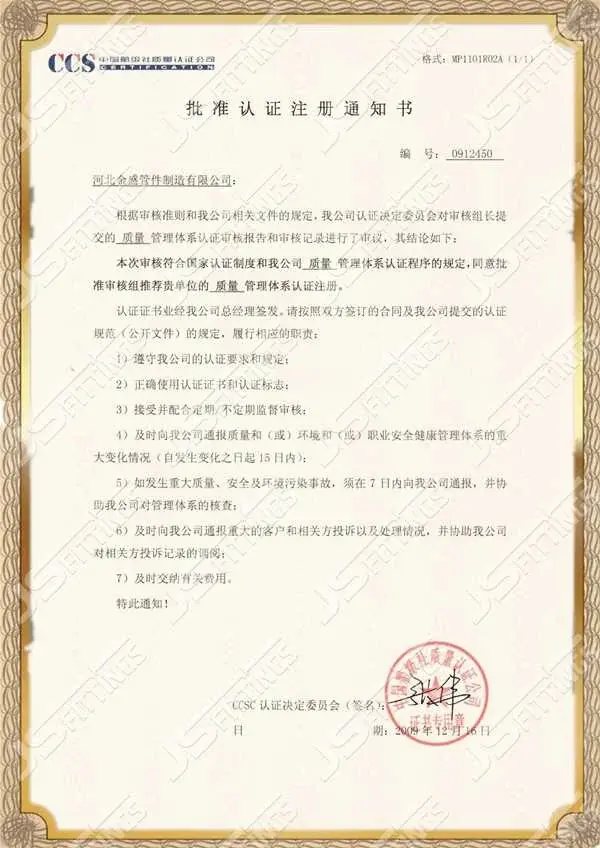

Certificates

Our commitment to quality is backed by international certifications:

- ISO 9001:2015 Quality Management System

- CE Marking for European market compliance

- GOST-R certification for Russian market standards

- API Spec Q1 for oil and gas industry requirements

FAQ

Q1: What is the standard length of your products?

A1: Our standard lengths are 6 meters and 12 meters. However, we can accommodate custom lengths based on your project requirements.

Q2: Can you provide pipes with custom threading or end preparations?

A2: Yes, we offer various end preparations including plain ends, beveled ends, and threaded ends (NPT or BSPT) to suit your specific needs.

Q3: What is the typical lead time for bulk orders?

A3: Lead times vary depending on order volume and complexity. For standard products, we typically aim for 2-4 weeks. Please contact us for a precise estimate based on your requirements.

Q4: Do you offer any corrosion protection options?

A4: Yes, we provide black phosphate coating as standard. For enhanced protection, we can offer hot-dip galvanization or other specialized coatings upon request.

Q5: Can you assist with material selection for my project?

A5: Absolutely. Our experienced technical team can help you choose the most suitable product grade and specifications based on your application and project requirements.

Contact Us

Ready to discuss your black mild steel pipe needs? Our dedicated team is here to assist you:

Email: admin@chinajsgj.com

Phone: +8618003119682

At Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd, we're committed to delivering high-quality products that meet your exact specifications. With our extensive experience, advanced manufacturing capabilities, and commitment to customer satisfaction, we're your ideal partner for all your industrial piping needs. Contact us today to request a quote or discuss your project requirements!

Learn about our latest products and discounts through SMS or email