- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

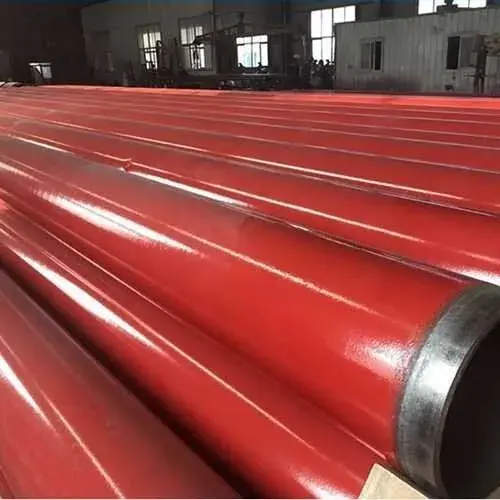

Fusion Bonded Epoxy Coated Carbon Steel Pipe

2. Dual-standard certified steel pipes | API 5L + EN 10219 dual compliance assurance

3. Precision Cutting Services | Ready-to-use pipe end treatments

4. Oil and Gas Project Logistics System | Exclusive Shipping Solutions Covering Central Asia/Middle East

5. Compliant with International Standards: ASTM、ASME、API 5L/11CT、DIN、EN, ISO、JIS、GOST

Fusion Bonded Epoxy Coated Carbon Steel Pipe: Corrosion Protection for Critical Infrastructure

Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd is a leading manufacturer and supplier of Fusion Bonded Epoxy Coated Carbon Steel Pipe. With 39 years of expertise, our state-of-the-art 35,000 m² facility houses advanced production lines delivering 30,000 tons annually of high-quality piping solutions. Our products offer superior corrosion resistance, extended service life, and compliance with international standards, making them ideal for oil & gas, water treatment, and industrial applications.

Key Features

- Exceptional Corrosion Protection: Our FBE coating provides a robust barrier against harsh environments.

- Extended Service Life: Significantly reduces maintenance costs and downtime.

- Chemical Resistance: Withstands exposure to various chemicals and aggressive fluids.

- Temperature Performance: Suitable for service temperatures from -40°C to 110°C.

- Excellent Adhesion: The coating bonds strongly to the steel substrate, preventing under-film corrosion.

- Smooth Surface: Reduces friction and improves flow efficiency.

Product Types

- Straight Pipe Sections: Available in various lengths and diameters.

- Bends and Elbows: Coated fittings for directional changes.

- Custom Fabrications: Tailored solutions for specific project requirements.

Materials & Grades

- Base Pipe: Carbon steel (API 5L Gr. B, X42, X52, X60, X65, X70)

- Coating: High-performance fusion bonded epoxy powder

Surface Treatment

- Surface Preparation: Automated grit blasting to achieve optimal surface profile for Fusion Bonded Epoxy Coated Carbon Steel Pipe.

- Preheating: Controlled heating to ensure proper coating adhesion.

- Powder Application: Electrostatic spray for uniform coverage.

- Curing: Precisely controlled heat treatment for optimal coating properties.

Dimensional Tolerance Checks(Per ASTM A530/API 5L)

|

Parameter |

Tolerance |

Instrument Used |

|

Outer Diameter(OD) |

±1%of nominal OD (or±0.79mm) |

Pi tape/Laser micrometer |

|

Wall Thickness(WT) |

±12.5%(SCH40 and below) |

Ultrasonic thickness gauge(UTG) |

|

Length |

±3mm for random,±6mm for cut-length |

Calibrated tape measure |

|

Straightness |

≤0.2%of total length |

Optical comparator |

|

Bevel Angle (for welding) |

30°-35°(±5°) |

Bevel protractor |

Visual &Surface Inspection

·Defect Identification:

o Lamination- Check for delamination near pipe ends

o Scratches/Dents -Max 5%of WT depth allowed (per ASME B31.3)

o Rust &Mill Scale-Controlled by SSPC-SP6(Commercial Blast Cleaning)

● Method:

o White light inspection(10,000 lux minimum)

o Dye penetrant test(PT)for surface cracks

Applications

- Oil and Gas Pipelines

- Water Transmission Systems

- Wastewater Treatment Plants

- Chemical Processing Facilities

- Offshore Platforms

- Underground and Submarine Pipelines

Packaging & Delivery

- End Caps: Protective covers to prevent coating damage during transport.

- Wooden Crates: Secure packaging for long-distance shipping.

- Custom Palletization: Optimized for efficient handling and storage.

- Global Logistics: Reliable delivery through our established shipping network.

Quality Control

- Coating Thickness: Regular measurements to ensure uniform application.

- Holiday Detection: 100% inspection for coating continuity.

- Adhesion Testing: Pull-off tests to verify coating bond strength.

- Cathodic Disbondment: Rigorous testing to ensure long-term performance.

- Chemical Resistance: Exposure tests for specific service environments.

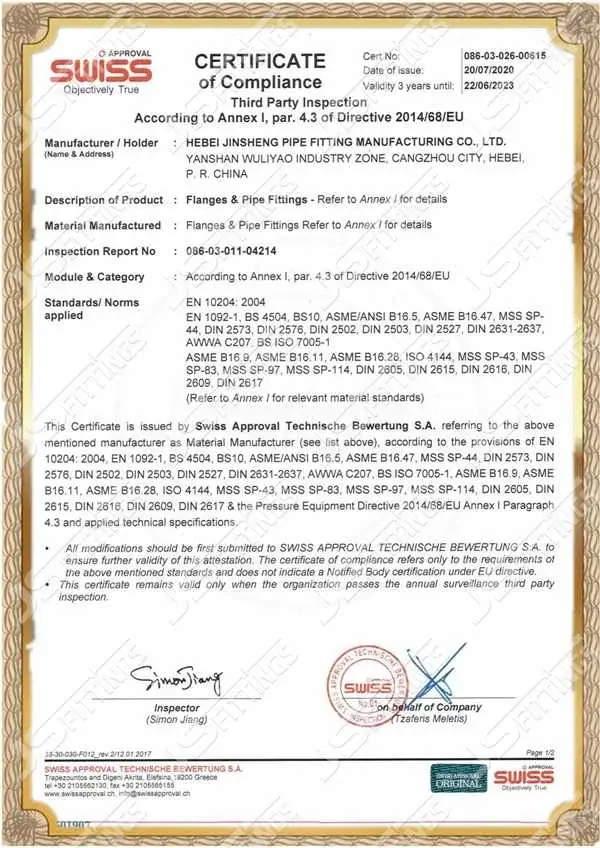

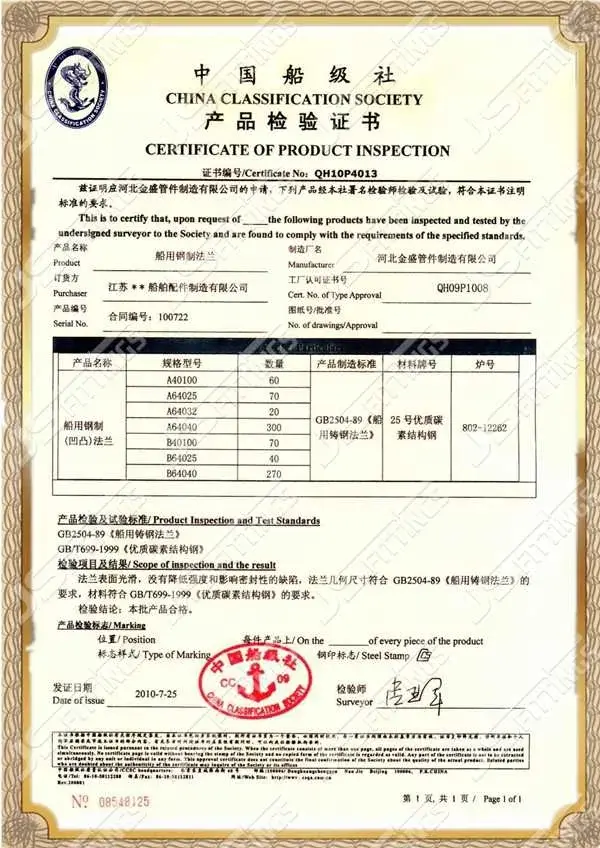

Certificates

- ISO 9001:2015 Quality Management System

- API 5L Certification for Line Pipe Manufacturing

- NACE Certified Coating Inspectors on Staff

- CE Marking for European Market Compliance

- NSF/ANSI 61 Certification for Potable Water Systems (where applicable)

- Our Business Partner

FAQ

Q: What is the typical coating thickness for your FBE coated pipes?

A: Our standard coating thickness ranges from 14 to 16 mils (350-400 microns), but we can adjust based on specific project requirements.

Q: Can you provide custom pipe lengths?

A: Yes, we offer cut-to-length services to meet your exact specifications.

Q: How does FBE coating compare to other corrosion protection methods?

A: FBE coating offers superior adhesion, Chemical resistance, and durability compared to many traditional coatings, resulting in longer service life and reduced maintenance costs.

Q: What is the lead time for large orders of the product?

A: Lead times vary based on order volume and specifications. For bulk orders, we typically estimate 4-8 weeks, but please contact us for a precise quote.

Q: Do you offer field joint coating solutions?

A: Yes, we provide compatible field joint coating systems and can offer technical support for on-site application.

Contact Us

Ready to enhance your infrastructure with our high-performance Fusion Bonded Epoxy Coated Carbon Steel Pipe? Our team of experts is here to assist you with specifications, quotes, and technical support.

Email: admin@chinajsgj.com

Phone: +8618003119682

Trust Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd for your critical piping needs. With our advanced manufacturing capabilities, rigorous quality control, and commitment to customer satisfaction, we deliver product that stands the test of time. Contact us today to discuss how we can support your next project with our corrosion-resistant piping solutions.

Learn about our latest products and discounts through SMS or email

_1755158680854.webp)