- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Schedule 40 ERW Steel Pipe

2. Dual-standard certified steel pipes | API 5L + EN 10219 dual compliance assurance

3. Precision Cutting Services | Ready-to-use pipe end treatments

4. Oil and Gas Project Logistics System | Exclusive Shipping Solutions Covering Central Asia/Middle East

5. Compliant with International Standards: ASTM、ASME、API 5L/14CT、DIN、EN, ISO、JIS、GOST

Schedule 40 Erw Steel Pipe

Product Overview

JS FITTING's Schedule 40 Erw Steel Pipe delivers industry-standard carbon steel piping solutions engineered to ANSI/ASME B36.10M specifications. Our electric resistance welding process transforms flat steel strips into cylindrical pipes with precision wall thickness tolerances. This cost-effective solution addresses your need for reliable fluid transport and structural piping without the capital expenditure of seamless alternatives. With 42 years manufacturing expertise and 30,000-ton annual capacity, we guarantee stable supply for large-scale projects. API 5L and EN 10219 dual-standard compliance ensures immediate deployment across oil, gas, and construction applications.

Precision Manufacturing Process

· Cold-forming flat steel strips with high-frequency electrical current welding

· Uniform wall thickness distribution for consistent performance

· Tighter dimensional tolerances compared to seamless alternatives

Dual-Standard Compliance

· API 5L and EN 10219 certified for international projects

· ASTM, ASME, DIN, ISO, JIS, and GOST standard conformity

· Ready-to-deploy across multiple regulatory environments

Cost-Effective Solution

· Lower material costs than seamless piping for moderate pressure applications

· Reduced lead times through streamlined production process

· Bulk pricing available for wholesale orders

Industrial-Grade Reliability

· Consistent structural strength for fluid transport systems

· Corrosion-resistant properties for long-term service life

· Compatible with automated welding and fitting processes

Technical Specifications

|

Parameter |

Range |

Standard |

|

Outside Diameter |

1/8" - 26" (10.3mm - 1219mm) |

ANSI/ASME B36.10M |

|

Wall Thickness |

0.068" - 1.031" (1.73mm - 26.19mm) |

Schedule 40 STD |

|

Length |

6m, 12m, or custom cut-to-length |

API 5L |

|

Material Grade |

A53 Grade B, X42-X70 |

ASTM/API Standards |

|

Pressure Rating |

150-3000 PSI (depending on size) |

ASME B31.3 |

|

Temperature Range |

-29°C to 343°C (650°F) |

API 5L specification |

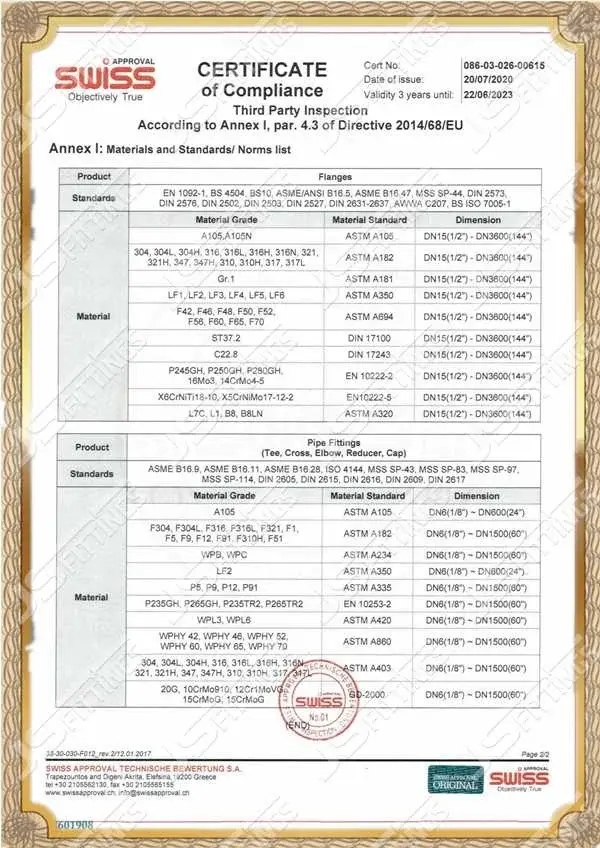

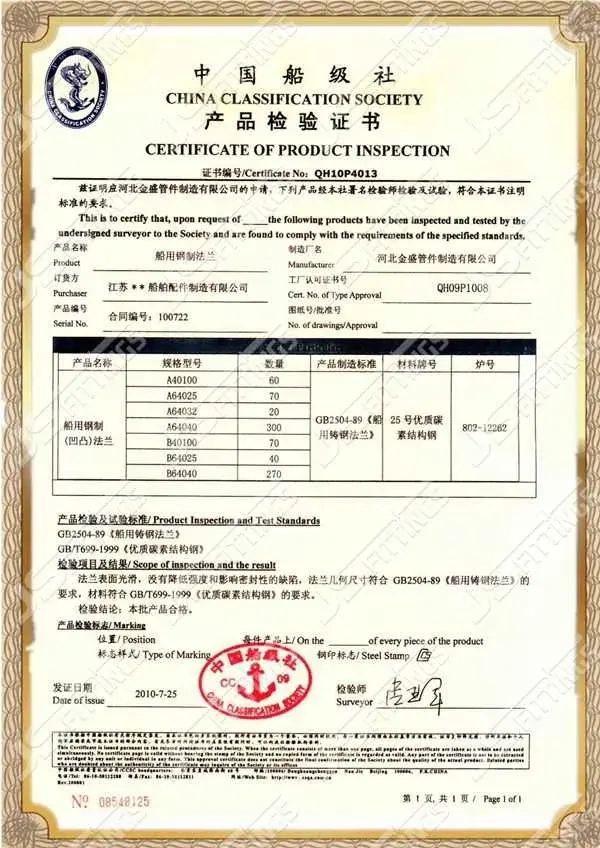

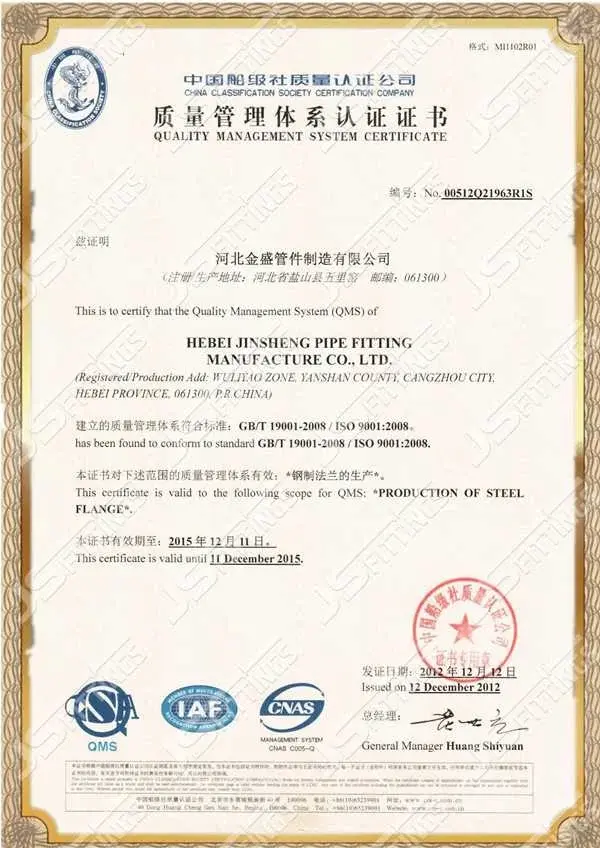

Standards & Certifications

· Manufacturing Standards: ASTM A53, API 5L, EN 10219

· Quality Certifications: ISO 9001:2015, CE, GOST-R

· Industry Approvals: PETROBRAS certified for oil & gas applications

· Testing Standards: ASME B31.3, API 5L PSL1/PSL2

· Inspection: 100% dimensional verification and hydrostatic testing

Chemical Composition & Mechanical Properties

Chemical Composition (A53 Grade B)

· Carbon (C): ≤0.30%

· Manganese (Mn): ≤1.20%

· Phosphorus (P): ≤0.05%

· Sulfur (S): ≤0.045%

· Silicon (Si): ≥0.10%

Mechanical Properties

· Tensile Strength: 415-565 MPa

· Yield Strength: ≥240 MPa

· Elongation: ≥23%

· Hardness: ≤197 HB

Manufacturing Process

Our electric resistance welding process begins with precision-cut steel strips formed into cylindrical shapes through cold-forming techniques. High-frequency electrical current creates molecular bonding at strip edges without filler metal addition. Post-welding normalization ensures uniform grain structure throughout the pipe wall. Each pipe undergoes dimensional inspection and hydrostatic testing before final quality approval.

Surface Finish & Coating Options

Standard Finishes

· Black iron finish for general applications

· Hot-dip galvanized coating for corrosion protection

· Internal/external epoxy coating for specialized environments

Custom Coating Services

· 3PE coating for underground applications

· FBE (Fusion Bonded Epoxy) for enhanced durability

· Custom color coding for project identification

Applications

Water Distribution Systems

Residential, commercial, and industrial water supply networks benefit from our pipes' corrosion resistance and leak-tight performance.

Gas Transmission Networks

Natural gas distribution systems rely on our Schedule 40 Erw Steel Pipe for safe, long-term gas transport with proper pressure ratings.

Structural Construction

Foundation piling, building support systems, and infrastructure projects utilize our pipes for load-bearing applications.

Industrial Process Piping

Chemical processing, Power Generation, and manufacturing facilities depend on our pipes for reliable fluid handling systems.

Packaging & Delivery

Standard packaging includes protective end caps, bundling with steel strapping, and moisture-resistant wrapping. Our dedicated logistics network covers Central Asia and Middle East regions with specialized handling for oil and gas projects. Delivery timeframes typically range 15-25 days depending on order volume and destination.

Certificates

Our commitment to quality is backed by international certifications:

- ISO 9001:2015

- API 5L

- CE marking

- GOST-R

These certifications demonstrate our adherence to global quality standards and regulatory requirements.

Customization Service

· Cut-to-length services with precision beveling

· Threading and coupling installation

· Custom marking and identification systems

· Special packaging for project requirements

· Expedited production for urgent deliveries

Quality Control

Every pipe undergoes comprehensive testing including dimensional verification, wall thickness measurement, and hydrostatic pressure testing. Our quality management system follows ISO 9001:2015 protocols with full traceability documentation. Third-party inspection services available upon request for critical applications.

Customer Reviews

"We tested the pipes extensively, and their performance exceeded expectations. The wall thickness consistency and weld quality impressed our engineering team."

"JS FITTINGS delivered exactly what we needed - technically compliant pipes at competitive pricing. Their export documentation was flawless."

"The production efficiency and delivery speed helped keep our project on schedule. Quality remained consistent throughout our large order."

FAQ

Q: Is your Schedule 40 ERW pipe suitable for fire sprinkler systems?

A: Yes, our A53 Grade B ERW pipes are strictly manufactured and tested for fire protection applications, offering excellent pressure resistance and easy threading for field installation.

Q: How do you guarantee the strength of the weld seam?

A: Each pipe undergoes High-Frequency Induction Welding followed by full-length seam annealing. This ensures the metallurgical structure of the weld matches the base metal, backed by 100% hydrostatic testing.

Q: What's the difference between ERW and seamless pipes?

A: ERW pipes offer tighter wall thickness tolerances and lower costs for moderate pressure applications, while maintaining comparable strength properties.

Q: Can you provide material test certificates?

A: Yes, we provide Mill Test Certificates (MTC) with complete chemical composition and mechanical property documentation for every shipment.

Q: What's your minimum order quantity?

A: Our MOQ varies by size and specification, typically starting at 10 tons for standard sizes with flexible terms for ongoing projects.

Q: Do you offer threading services?

A: Yes, we provide precision threading, beveling, and end preparation services to deliver ready-to-install pipes.

Contact Us

Ready to discuss your piping requirements? Contact our technical team at admin@jsfittings.com for detailed quotations and project consultation.

Learn about our latest products and discounts through SMS or email

_1758095958686.webp)