- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Spiral Submerged Arc steel Pipe

2. Dual-standard certified steel pipes | API 5L + EN 10219 dual compliance assurance

3. Precision Cutting Services | Ready-to-use pipe end treatments

4. Oil and Gas Project Logistics System | Exclusive Shipping Solutions Covering Central Asia/Middle East

5. Compliant with International Standards: ASTM、ASME、API 5L/15CT、DIN、EN, ISO、JIS、GOST

Spiral Submerged Arc Steel Pipes: Premium Quality for Critical Infrastructure

Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd is a leading manufacturer and supplier of Spiral Submerged Arc steel Pipe. With 39 years of expertise, our state-of-the-art facility produces high-quality pipes that meet international standards. Our product advantages include advanced automated production, mass manufacturing capabilities, and rigorous quality control.

Key Features

- Superior weld integrity

- Excellent corrosion resistance

- High pressure-bearing capacity

- Uniform wall thickness

- Customizable lengths up to 12 meters

- Cost-effective for long-distance pipelines

Product Types

Our product range includes:

- Single Submerged Arc Welded (SSAW) Pipes

- Double Submerged Arc Welded (DSAW) Pipes

- Longitudinal Submerged Arc Welded (LSAW) Pipes

Available in diameters from 219mm to 3500mm and wall thicknesses from 6mm to 25mm.

Materials & Grades

We offer pipes in various steel grades to suit your project requirements:

- Carbon Steel: API 5L Gr. B, X42, X52, X60, X65, X70

- Low Alloy Steel: ASTM A516 Gr. 60, 65, 70

- Stainless Steel: 304, 316L, 321, 347

Surface Treatment

Choose from multiple surface treatment options:

- Black painting

- 3LPE/3LPP coating

- FBE coating

- Galvanization

- Customized anti-corrosion coatings

Applications

Our Spiral Submerged Arc steel Pipe is ideal for:

- Oil and gas transmission pipelines

- Water supply and sewage systems

- Piling and foundation engineering

- Offshore platforms and marine structures

- Large-scale construction projects

Packaging & Delivery

- Standard export packaging with end caps and steel straps

- Bulk shipment or container loading available

- Dedicated logistics network for timely global delivery

Quality Control

We maintain strict quality control measures:

- 100% visual inspection

- Hydrostatic testing

- Ultrasonic testing

- X-ray inspection

- Mechanical property testing

1 Dimensional Tolerance Checks(Per ASTM A530/API 5L)

|

Parameter |

Tolerance |

Instrument Used |

|

Outer Diameter(OD) |

±1%of nominal OD (or±0.79mm) |

Pi tape/Laser micrometer |

|

Wall Thickness(WT) |

±12.5%(SCH40 and below) |

Ultrasonic thickness gauge(UTG) |

|

Length |

±3mm for random,±6mm for cut-length |

Calibrated tape measure |

|

Straightness |

≤0.2%of total length |

Optical comparator |

|

Bevel Angle (for welding) |

30°-35°(±5°) |

Bevel protractor |

Visual &Surface Inspection

·Defect Identification:

o Lamination- Check for delamination near pipe ends

o Scratches/Dents -Max 5%of WT depth allowed (per ASME B31.3)

o Rust &Mill Scale-Controlled by SSPC-SP6(Commercial Blast Cleaning)

● Method:

o White light inspection(10,000 lux minimum)

o Dye penetrant test(PT)for surface cracks

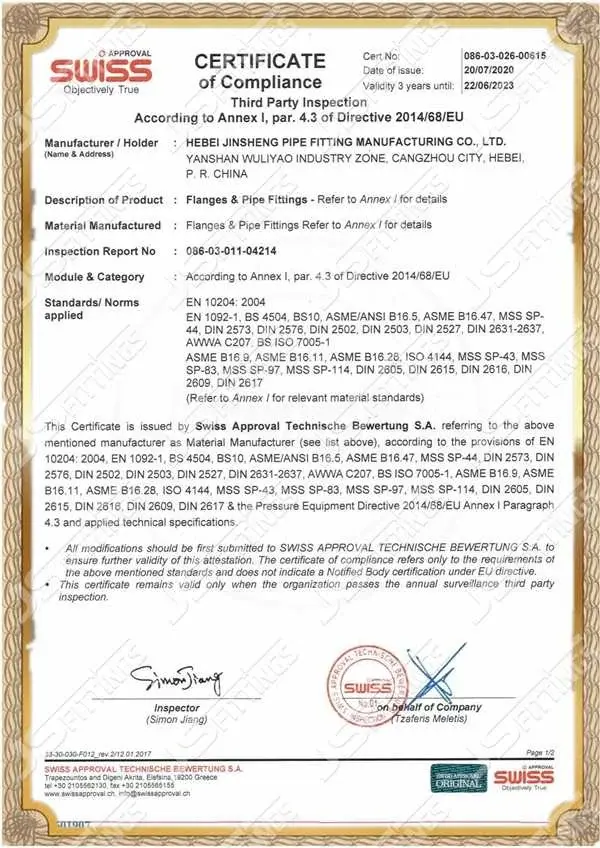

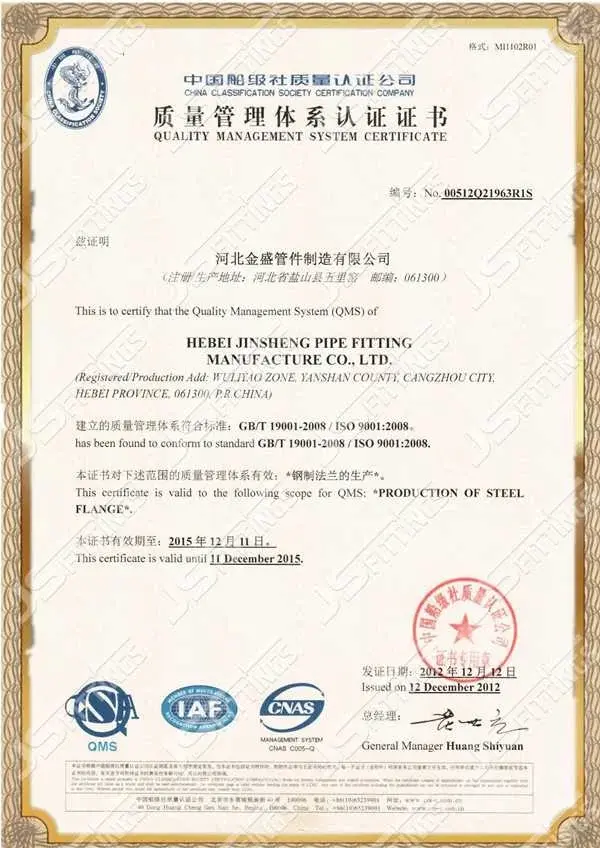

Certificates

Our products meet international standards and are certified by:

- ISO 9001:2015

- API 5L

- CE marking

- GOST-R

- PETROBRAS

FAQ

Q: What is the minimum order quantity for the products?

A: Our minimum order quantity is typically 20 tons, but we can accommodate smaller orders for special requirements.

Q: Can you provide custom specifications for your pipes?

A: Yes, we offer customization in diameter, wall thickness, length, and coating options to meet your specific project needs.

Q: What is the lead time for bulk orders?

A: Lead times vary depending on order size and specifications. Generally, we can deliver within 30-45 days for standard orders.

Q: Do you offer technical support for installation and maintenance?

A: Absolutely. Our team of experts provides comprehensive technical support, including welding guidance and corrosion prevention advice.

Q: How do you ensure consistent quality across large orders?

A: We employ advanced automated production lines and rigorous quality control processes at every stage of manufacturing to maintain consistent high quality.

Contact Us

Ready to elevate your infrastructure projects with our premium Spiral Submerged Arc steel Pipe? Our team is here to assist you with specifications, quotes, and technical information.

Email: admin@chinajsgj.com

Phone: +8618003119682

Trust Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd for your critical infrastructure needs. With our 39 years of experience, cutting-edge manufacturing processes, and commitment to quality, we deliver product that stands the test of time. contact us today to discuss your project requirements and experience the Jinsheng difference in reliability, performance, and customer satisfaction.

Learn about our latest products and discounts through SMS or email

_1758097857386.webp)