- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

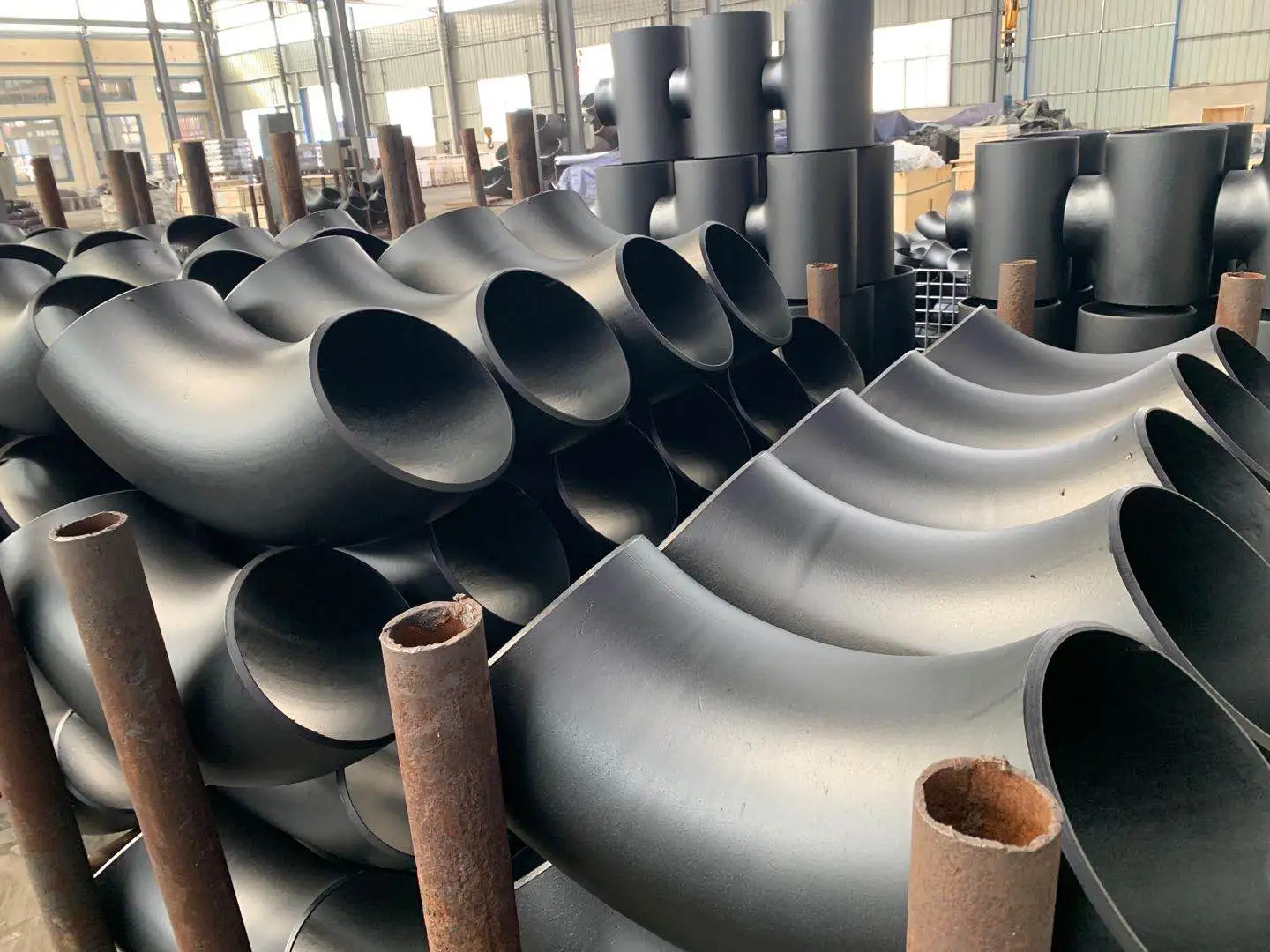

Carbon Steel 180-degree Schedule 40 Butt Weld Elbow

Master Full Flow Reversal with Our High-Performance Carbon Steel 180-Degree Schedule 40 Butt Weld Elbows

In industrial piping systems where a complete U-turn in flow direction is required, compromise on component quality is simply not an option. Our Carbon Steel 180-Degree Schedule 40 Butt Weld Elbows are meticulously designed and manufactured to deliver uncompromising strength, reliability, and precision. These essential fittings are crafted to ensure seamless, efficient, and leak-free flow reversal, making them indispensable for a wide array of demanding applications across various industries.

The Indispensable Role of a 180-Degree Elbow

A 180-degree return bend, often referred to as a "U-bend," is critical for compact system designs and heat exchanger applications where space is at a premium and efficient heat transfer is paramount. Our carbon steel variants, with their Schedule 40 wall thickness, provide the robust solution needed to handle the rigorous conditions often found in these environments.

Why Our Carbon Steel 180-Degree Schedule 40 Elbows Stand Out:

Exceptional Material Strength: Forged from premium carbon steel (commonly ASTM A234 WPB), these elbows offer superior tensile strength and resistance to fatigue, ensuring a prolonged operational life even under continuous stress and pressure fluctuations.

Built to Endure: Schedule 40 Wall Thickness: The robust Schedule 40 designation signifies a substantial wall thickness, providing enhanced pressure containment capabilities and structural integrity. This is crucial for systems operating at elevated pressures and temperatures, guaranteeing safety and reliability.

Complete Flow Reversal, Minimized Turbulence: The smooth internal contours and precise 180-degree radius are engineered to facilitate a full and efficient reversal of flow with minimal pressure drop and reduced turbulence. This design promotes energy efficiency and protects downstream equipment.

Secure, Leak-Proof Butt Weld Connections: Designed for butt welding, these elbows integrate flawlessly into your pipeline. Butt welding creates a monolithic connection that is inherently leak-proof, highly resistant to vibration, and provides maximum structural strength without obstructing flow.

Versatility Across Industries: These specialized elbows are vital in applications ranging from heat exchangers in power plants and refineries, to compact loop designs in HVAC systems, and critical process lines in Chemical and petrochemical facilities.

Cost-Effective Durability: Carbon steel offers an optimal balance between high performance, exceptional durability, and competitive cost, providing a long-term, reliable solution that contributes positively to your project's bottom line.

Adherence to Global Standards: Manufactured in strict accordance with international standards like ASME B16.9 and material specifications such as ASTM A234 WPB, our fittings ensure guaranteed quality, dimensional accuracy, and universal compatibility.

Core Technical Specifications

Material Grade: High-quality Carbon Steel (e.g., ASTM A234 Grade WPB)

Nominal Pipe Size (NPS): Available in a comprehensive range, typically from 1/2" to 24" NPS and custom sizes on request.

Wall Thickness: Schedule 40 (SCH 40)

Bend Angle: 180 Degrees

Radius Type: Long Radius (LR) is standard for smooth flow, Short Radius (SR) also available for compact installations.

Manufacturing Standards: ASME B16.9 for dimensions, ASTM A234 for material.

End Preparation: Beveled ends for butt welding.

Surface Finish: Mill finish, black paint, or primer coating available.

Testing & Certification: Comprehensive material test reports (MTRs) provided; options for additional non-destructive testing (NDT) upon request.

Where Reliability of Return Bends is Paramount?

Our Carbon Steel 180-Degree Schedule 40 Butt Weld Elbows are indispensable for:

Heat Exchanger Units: Facilitating efficient fluid pass-through for optimal heat transfer.

Boiler Systems: Managing steam and water lines within a confined space.

Petrochemical Plants: Guiding critical process fluids in compact configurations.

Refineries: Handling various hydrocarbon streams safely and efficiently.

HVAC and Refrigeration Systems: Creating compact loops for refrigerant and water lines.

Any application requiring a complete, space-saving directional change in fluid flow.

Seamless Integration and Lasting Performance

Installation of butt weld fittings requires professional, certified welding to achieve the robust, permanent connection they are designed for. When correctly installed, these carbon steel elbows provide exceptional longevity with minimal maintenance requirements. We always recommend periodic inspection in line with industry best practices to ensure continued optimal performance.

Choosing the right components is a direct investment in the long-term efficiency and safety of your operations. Our Carbon Steel 180-Degree Schedule 40 Butt Weld Elbows represent the pinnacle of engineering excellence, delivering the unwavering reliability and performance essential for the most demanding industrial environments.

Contact our team today for a detailed quote or to discuss your project-specific needs.

Email: admin@chinajsgj.com

Phone: +8618003119682

Learn about our latest products and discounts through SMS or email

_1761641000494.webp)