- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

ASME B16.9: Certification & Compliance?

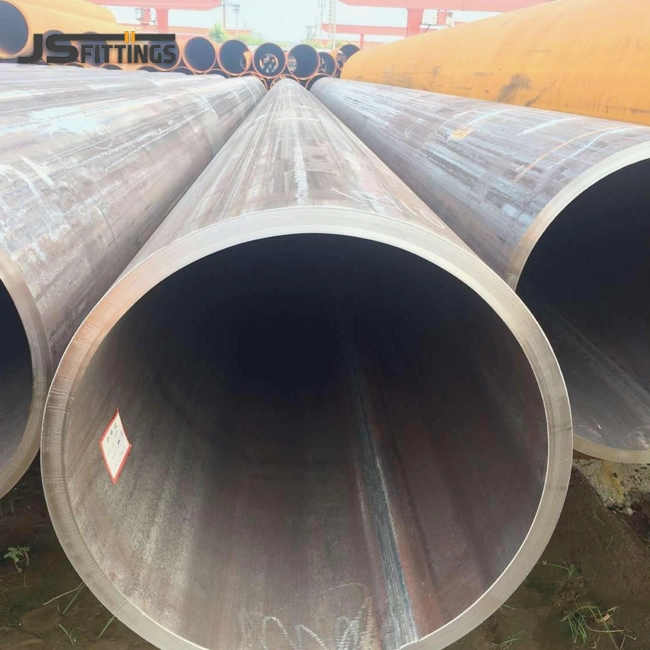

ASME B16.9: Certification & Compliance represents the cornerstone of industrial piping integrity, establishing rigorous standards that ensure safety, reliability, and performance across critical infrastructure projects worldwide. Understanding the comprehensive certification requirements and compliance protocols for ASME B16.9 Fittings enables engineers, procurement specialists, and project managers to make informed decisions that protect both personnel and assets. This detailed exploration examines the multi-layered certification processes, regulatory compliance frameworks, and quality assurance protocols that validate ASME B16.9 Fittings for use in demanding industrial environments where failure is not an option.

Certification Standards and Regulatory Framework

International Standards Compliance

The certification landscape for ASME B16.9 Fittings encompasses multiple international standards that ensure global acceptance and regulatory compliance across diverse markets. Primary compliance with ASME B16.9 establishes the foundation for dimensional accuracy, material specifications, and testing requirements that govern manufacturing processes. Concurrent adherence to EN 10253 European standards ensures compatibility with European Union directives and facilitates market access across member nations. GOST standards compliance enables deployment in Russian Federation and Commonwealth of Independent States projects, while maintaining alignment with regional engineering practices and material specifications. These parallel certifications demonstrate that ASME B16.9 Fittings meet or exceed the most stringent international requirements, providing confidence for multinational projects where regulatory harmonization is essential for successful implementation and long-term operational success.

Quality Management System Certifications

ISO 9001 quality management system certification forms the operational backbone for ASME B16.9 Fittings manufacturing, establishing systematic approaches to quality control, process improvement, and customer satisfaction. This comprehensive framework encompasses design controls, procurement procedures, manufacturing processes, and post-delivery support that ensure consistent product quality throughout the entire lifecycle. CE marking under the Pressure Equipment Directive (PED) 2014/68/EU validates conformity with European safety requirements for pressure-bearing equipment, enabling unrestricted market access across European Union territories. The certification process involves rigorous assessment of design capabilities, manufacturing processes, quality systems, and technical competencies by notified bodies that verify compliance with essential safety requirements. These certifications provide ASME B16.9 Fittings with the regulatory credentials necessary for deployment in regulated industries where safety and reliability are paramount concerns.

Industry-Specific Approvals

Major industry operators including NIOC (National Iranian Oil Company), ADNOC (Abu Dhabi National Oil Company), and PETROBRAS have developed stringent approval processes that validate ASME B16.9 Fittings for use in their critical infrastructure projects. These approvals typically involve comprehensive factory audits, material testing verification, quality system assessments, and ongoing surveillance activities that ensure sustained compliance with operator-specific requirements. The approval process examines manufacturing capabilities, technical expertise, quality control procedures, and supply chain management practices to verify the ability to consistently deliver products that meet demanding operational requirements. Successfully achieving these industry-specific approvals demonstrates that ASME B16.9 Fittings have undergone the most rigorous evaluation processes in the industry, providing procurement teams with confidence in product quality, delivery reliability, and long-term performance in challenging operational environments.

Testing Protocols and Quality Assurance

Material Verification and Traceability

Comprehensive material verification processes for ASME B16.9 Fittings begin with certified raw material sourcing from approved suppliers who provide complete chemical composition analysis and mechanical property certification. Heat treatment processes are carefully controlled and documented to optimize metallurgical properties while maintaining traceability throughout the manufacturing sequence. Each batch of fittings undergoes chemical analysis to verify compliance with specified grade requirements, while mechanical testing validates tensile strength, yield strength, elongation, and impact resistance properties. Material test certificates accompany every shipment of ASME B16.9 Fittings, providing complete documentation of material properties, heat treatment parameters, and test results that enable full traceability from raw material source through final installation. This comprehensive approach ensures that material properties remain consistent and predictable throughout the service life of the fittings.

Dimensional and Visual Inspection

Precision dimensional inspection of ASME B16.9 Fittings utilizes advanced measurement technologies including coordinate measuring machines, laser scanning systems, and optical comparators that verify compliance with specified tolerances. Critical dimensions including center-to-end measurements, wall thickness uniformity, and socket preparation geometry are validated against drawing specifications with documented measurement uncertainty. Visual inspection procedures identify surface defects, manufacturing irregularities, and finish quality issues that could compromise performance or appearance. Surface roughness measurements ensure optimal conditions for welding operations and protective coating adhesion. Each ASME B16.9 Fittings undergoes 100% inspection before shipment, with detailed dimensional reports and photographic documentation providing complete verification of conformance to specified requirements and enabling confident acceptance by installation teams.

Pressure Testing and Performance Validation

Hydrostatic pressure testing represents the final validation step for ASME B16.9 Fittings, subjecting each component to pressures exceeding normal operating conditions to verify structural integrity and leak-tight performance. Test pressures are calculated based on material properties, wall thickness, and safety factors specified in applicable codes and standards. Pneumatic testing using controlled air pressure provides alternative verification for applications where water contamination is unacceptable. Non-destructive testing methods including radiographic examination, ultrasonic testing, and magnetic particle inspection identify internal defects that could compromise long-term reliability. These comprehensive testing protocols ensure that ASME B16.9 Fittings consistently meet or exceed performance requirements, providing confidence for critical applications where failure could result in safety hazards, environmental contamination, or significant economic losses.

Compliance Documentation and Certification Management

Technical Documentation Requirements

Complete technical documentation for ASME B16.9 Fittings encompasses design calculations, material specifications, manufacturing procedures, testing protocols, and quality control records that demonstrate full compliance with applicable standards and customer requirements. Design verification documents validate dimensional accuracy, stress analysis calculations, and compatibility with associated piping components. Manufacturing procedure specifications detail forming processes, heat treatment parameters, surface treatment procedures, and inspection requirements that ensure consistent product quality. Test certificates document material properties, dimensional verification, pressure testing results, and non-destructive examination findings that provide complete assurance of product conformance. This comprehensive documentation package enables ASME B16.9 Fittings to be confidently specified for critical applications where regulatory compliance and performance verification are essential requirements.

Certification Maintenance and Continuous Improvement

Ongoing certification maintenance for ASME B16.9 Fittings requires continuous monitoring of manufacturing processes, quality systems, and product performance to ensure sustained compliance with evolving standards and customer expectations. Regular internal audits verify adherence to established procedures while identifying opportunities for process improvement and cost optimization. External surveillance audits by certification bodies validate continued compliance with quality management systems and product certification requirements. Customer feedback and field performance data provide valuable insights for product development and manufacturing process refinement. This commitment to continuous improvement ensures that ASME B16.9 Fittings consistently incorporate the latest technological advances while maintaining the highest levels of quality and reliability that customers expect from certified products.

Supply Chain Compliance Management

Effective supply chain management for ASME B16.9 Fittings requires careful selection and ongoing evaluation of raw material suppliers, subcontractors, and service providers to ensure compliance with quality requirements and certification standards. Supplier audits verify quality systems, technical capabilities, and compliance with environmental and social responsibility requirements. Incoming material inspection validates chemical composition, mechanical properties, and dimensional characteristics against specified requirements. Subcontractor qualification procedures ensure that outsourced processes maintain the same quality standards applied to internal operations. This comprehensive supply chain management approach ensures that ASME B16.9 Fittings consistently meet certification requirements while maintaining the flexibility to respond to changing market demands and customer specifications.

Conclusion

ASME B16.9: Certification & Compliance establishes the foundation for safe, reliable piping systems across diverse industrial applications. The comprehensive certification framework, rigorous testing protocols, and thorough documentation requirements ensure that ASME B16.9 Fittings consistently meet the highest quality standards. With over four decades of manufacturing excellence, advanced production capabilities, and multiple international certifications, these fittings provide unmatched reliability for critical infrastructure projects worldwide.

FAQ

1. What certifications are required for ASME B16.9 Fittings?

ASME B16.9 Fittings require compliance with ASME B16.9 standard, along with ISO 9001 quality management certification, CE/PED 2014/68/EU marking for European markets, and industry-specific approvals from major operators like NIOC, ADNOC, and PETROBRAS for specialized applications.

2. How are ASME B16.9 Fittings tested for compliance?

ASME B16.9 Fittings undergo comprehensive testing including material chemical analysis, mechanical property verification, dimensional inspection, hydrostatic pressure testing, and non-destructive examination to ensure full compliance with applicable standards and performance requirements.

3. What documentation accompanies ASME B16.9 Fittings?

Complete documentation for ASME B16.9 Fittings includes material test certificates, dimensional inspection reports, pressure test certificates, non-destructive testing records, and compliance declarations that provide full traceability and performance verification.

4. Which international standards apply to ASME B16.9 Fittings?

ASME B16.9 Fittings comply with multiple international standards including ASME B16.9, EN 10253, and GOST requirements, ensuring global acceptance and regulatory compliance across diverse markets and applications.

Premium Certified ASME B16.9 Fittings Manufacturers | JS FITTINGS

Trust JS FITTINGS for certified excellence in ASME B16.9 Fittings manufacturing, where 42 years of industry expertise combines with state-of-the-art technology across our 35,000 m² facility. Our four advanced production lines deliver 30,000 tons annually of fully certified fittings, flanges, and pipes that exceed ASTM and EN standards. With prestigious ISO 9001, CE, and PETROBRAS certifications validating our uncompromising commitment to quality, we serve oil & gas, shipbuilding, and construction sectors worldwide. Our continuous process improvement initiatives ensure competitively priced, high-performance ASME B16.9 Fittings that meet the most demanding industrial applications. Ready to secure certified quality for your next project? Contact our certification experts at admin@chinajsgj.com for comprehensive compliance solutions and competitive quotations.

References

1. American Society of Mechanical Engineers. "ASME B16.9 Factory-Made Wrought Buttwelding Fittings: Certification Requirements." New York: ASME Press, 2018.

2. European Committee for Standardization. "EN 10253 Butt-welding Pipe Fittings: Compliance and Testing." Brussels: CEN Publications, 2019.

3. International Organization for Standardization. "ISO 9001 Quality Management Systems: Requirements for Industrial Manufacturing." Geneva: ISO Press, 2020.

4. Pressure Equipment Directive. "PED 2014/68/EU: Compliance Guide for Pressure Bearing Components." Brussels: European Commission, 2019.

5. Smith, Robert K. "Industrial Piping Certification: Standards, Testing, and Documentation." London: Technical Engineering Press, 2021.

6. Williams, Michael J. "Quality Assurance in Pipe Fitting Manufacturing: Certification Protocols and Best Practices." Houston: Industrial Publications, 2020.

Learn about our latest products and discounts through SMS or email