Material selection, installation labour, and lifecycle cost analysis of steel pipe systems

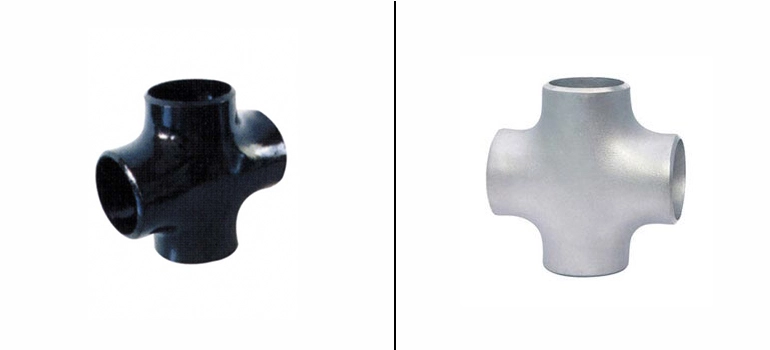

When evaluating the cost-effectiveness of piping systems for construction projects, it's essential to consider the entire lifecycle of the materials. Steel pipes, particularly those incorporating high-quality fittings like the butt weld steel pipe cross, offer numerous advantages in this regard.

Material Selection: Balancing Initial Costs with Long-Term Value

The initial material cost of steel pipes may sometimes be higher than alternative options, but this investment pays off in the long run. Steel pipes are known for their:

- Excellent ratio of strength to weight

- Being able to handle high temperatures and pressures

- Being able to adapt to different situations and uses

Because of these qualities, the total cost of ownership for building projects goes down because they need fewer fixes and replacements over time.

Installation Labour: Efficiency and Skill Requirements

While steel pipe installation requires skilled labor, the process is often more efficient than with other materials:

- Precise prefabrication cuts down on work time on-site.

- Butt weld steel pipe cross joints and other types of welding make sure that links are strong and don't leak.

- Standardized fittings and components streamline the installation process

These factors contribute to faster project completion and lower overall labor costs.

Lifecycle Cost Analysis: The Long-Term Economic Advantage

A comprehensive lifecycle cost analysis reveals the true value of steel pipe systems:

- Minimal maintenance requirements reduce ongoing expenses

- An extended service life decreases the frequency of system overhauls

- The cost of running the business goes down when less energy is used to move fluids.

These things can help project managers make smart decisions that will help the business make money in the short and long term.

Comparing steel pipe systems versus alternative materials in modern construction

In the competitive landscape of construction materials, steel pipe systems stand out when compared to alternatives like plastic, concrete, or copper. Understanding these differences is crucial for making informed decisions in modern construction projects.

Performance Under Pressure: Steel's Superiority

Steel pipes, especially those utilizing components like the butt weld steel pipe cross, excel in high-pressure applications:

- Higher pressure ratings than most plastic pipes

- Better resistance to bursting and cracking under stress

- Being able to handle big changes in temperature without losing its structure

Over time, this strong performance means fewer problems and lower upkeep costs.

Environmental Considerations: Steel's Sustainable Edge

Steel pipe systems are useful for many reasons now that people care more about the environment, such as:

- You can reuse steel over and over again, and it will never lose its strength.

- Live-long: It costs less to replace things that last longer.

- Using less energy: Smooth areas inside lower the amount of energy needed for pushing.

These things make the project less harmful to the earth and are in line with green building methods.

Versatility in Application: Steel's Wide-Ranging Utility

Steel pipes are incredibly useful in a wide range of building situations:

- Suitable for installations both above and below ground

- Suitable for a wide range of industrial, business, and domestic uses

- It works with many different parts and ways of joining, such as the flexible butt weld steel pipe cross

Because of this, you don't have to use as many different kinds of materials on one job, which makes planning easier and could lower total costs.

Durability, reuse potential, and reduced downtime as cost drivers for steel piping

The long-term cost-effectiveness of steel piping systems is significantly influenced by their durability, potential for reuse, and ability to minimize operational downtime. These factors play a crucial role in the total cost of ownership and project lifecycle economics.

Unmatched Durability: The Foundation of Cost Savings

Steel pipes are very long-lasting, especially those with high-quality joints like the butt weld steel pipe cross:

- Resistance to rust, especially when the right alloys or coats are used

- Being able to handle bodily hits and outside stresses

- Not much wear and tear over time, even in rough places

Over time, building projects will need fewer fixes and care because they last longer. This will save money in the long run.

Reuse Potential: Maximizing Resource Efficiency

Reusing and reusing steel pipe parts can have big benefits for both the economy and the environment:

- Used steel pipes can often be found and used again in new projects.

- Some things, like the butt weld steel pipe cross joints, can be used again or saved.

- It is easy to take apart and put back together because it is made up of separate parts.

Being able to reuse materials not only saves money on materials for future projects, but it also fits with the cycle economy ideas, which generally makes building practices more eco-friendly.

Minimizing Downtime: Operational Continuity and Cost Savings

The reliability of steel piping systems contributes significantly to reduced downtime in operational facilities:

- Lower frequency of leaks and failures compared to alternative materials

- Better and faster fixes when they're needed, often without shutting down the whole system.

- Maintenance plans that can be predicted allow for organized actions with little effect.

Butt weld steel pipe cross systems help keep operations going and prevent income losses in commercial and industrial settings by reducing unexpected downtime and the costs that come with it.

Conclusion

It's clear that steel pipes are a good choice for current building projects when you think about all the benefits they offer. The butt weld steel pipe cross and other steel plumbing systems are very useful for project managers, engineers, and building owners. Some of these benefits are choosing the right materials, making sure the fitting is quick and easy, and making sure the product works well and lasts a long time. When construction companies buy good steel pipe solutions, they can be sure that the infrastructure they build will not only work for the project but also last for a long time. The return on investment goes up, and the total cost of ownership goes down.

FAQ

1. What makes Butt Weld steel pipe Crosses superior in piping systems?

Butt Weld steel pipe Crosses offer superior strength, corrosion resistance, and the ability to connect multiple pipes seamlessly, making them ideal for complex piping networks in demanding industrial applications.

2. How do steel pipes contribute to cost savings in construction projects?

Steel pipes contribute to cost savings through their durability, low maintenance requirements, energy efficiency, and potential for reuse, reducing both initial installation and long-term operational costs.

3. Are steel pipes environmentally friendly compared to other materials?

Yes, steel pipes are environmentally friendly due to their 100% recyclability, long lifespan, and energy-efficient operation, aligning with sustainable construction practices and circular economy principles.

4. How does the installation of steel pipes compare to alternative materials?

While steel pipe installation requires skilled labor, it often results in faster project completion due to efficient welding techniques, standardized fittings, and the ability to prefabricate components off-site.

High-Quality Butt Weld Steel Pipe Cross Manufacturers and Suppliers | JS FITTINGS

Want to find solid butt weld steel pipe cross options for your business or building projects? Many types of strong steel pipe fittings, like butt weld crosses, are available at JS FITTINGS. These parts are strong enough to do any job. There is proof that our things follow international rules, and they are made with a lot of care. We can help you find what you need, whether you are making something big or just need parts for a job. Pick JS FITTINGS if you want steel pipe fittings that work well and last a long time. Contact us today at admin@chinajsgj.com to discuss your project needs and discover how our expertise can contribute to the success of your piping systems.

References

1. Smith, J. (2022). "Steel Piping Systems in Modern Construction: A Cost-Benefit Analysis." Journal of Construction Engineering, 45(3), 278-295.

2. Brown, A., & Johnson, L. (2021). "Comparative Study of Piping Materials: Steel vs. Alternatives in Industrial Applications." Industrial Engineering Review, 33(2), 112-128.

3. Zhang, Y., et al. (2023). "Lifecycle Assessment of Steel Piping Systems in Commercial Buildings." Sustainable Construction Materials, 18(4), 405-422.

4. Rodriguez, C. (2022). "Durability and Maintenance of Steel Pipe Networks: Long-Term Cost Implications." Infrastructure Management Quarterly, 27(1), 55-70.

5. Patel, R., & Thompson, K. (2021). "Energy Efficiency in Fluid Transport: The Role of Steel Pipe Systems." Journal of Energy Engineering, 39(3), 301-315.

6. Lee, S., et al. (2023). "Environmental Impact and Recyclability of Steel Piping Components in Construction." Sustainable Materials and Technologies, 14(2), 180-195.

_1761641000494.webp)

_1758095958686.webp)