- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Overview of Benefits for Steel Buttweld Fittings?

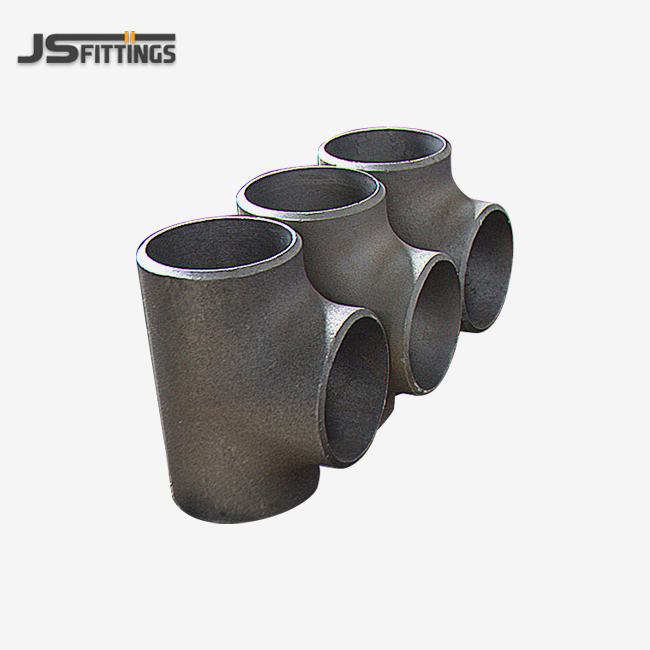

Steel Butt Weld Fittings speak to one of the most basic components in present day mechanical channeling frameworks, advertising unparalleled unwavering quality and execution over different applications. These precision-engineered components give consistent associations between channels, guaranteeing ideal stream characteristics and auxiliary astuteness. Understanding the comprehensive benefits of Steel Butt Weld Fittings empowers engineers and obtainment experts to make educated choices that specifically affect framework productivity, security, and long-term operational costs. From predominant mechanical properties to broad fabric choices, these fittings convey uncommon esteem over oil and gas, chemical preparing, and control era industries.

Superior Performance and Reliability Benefits

Enhanced Structural Integrity

Steel Butt Weld Fittings provide exceptional structural integrity through their welded connection method, which creates a continuous pipe wall without weak points or pressure drop zones. This seamless integration eliminates potential leak paths that commonly occur with threaded or flanged connections. The welding process creates a metallurgical bond that matches or exceeds the strength of the parent pipe material, ensuring uniform stress distribution throughout the system. Advanced manufacturing techniques ensure dimensional accuracy and consistent wall thickness, contributing to predictable performance under extreme pressure and temperature conditions. The absence of mechanical joints reduces maintenance requirements and extends system life significantly compared to alternative connection methods.

Superior Flow Characteristics

The smooth bore design of Steel Butt Weld Fittings minimizes pressure losses and turbulence within piping systems, optimizing fluid flow efficiency. Unlike threaded fittings that create flow restrictions, butt weld connections maintain consistent internal diameters throughout directional changes and transitions. This characteristic proves particularly valuable in high-velocity applications where pressure drop minimization directly impacts system performance and energy consumption. The streamlined internal geometry reduces erosion potential and particle accumulation, maintaining long-term flow efficiency. These benefits become increasingly significant in large-diameter systems where even minor pressure losses translate to substantial operational costs.

Temperature and Pressure Resistance

Steel Butt Weld Fittings demonstrate exceptional performance under extreme temperature and pressure conditions, making them ideal for demanding industrial applications. The welded construction eliminates gasket-dependent sealing systems that may fail under thermal cycling or high-pressure conditions. Material selection options including carbon steel, alloy steel, and stainless steel grades provide temperature resistance ranging from cryogenic to high-temperature applications exceeding 1000°F. The absence of threaded connections eliminates stress concentrations that could compromise system integrity under pressure fluctuations. This robust construction enables operation in applications where safety margins are critical and failure consequences are severe.

Comprehensive Material and Design Versatility

Extensive Material Selection Options

Steel Butt Weld Fittings offer unprecedented material versatility to meet specific application requirements across diverse industries. Carbon steel grades such as ASTM A234 WPB provide cost-effective solutions for standard pressure and temperature applications, while alloy steel grades including WP5, WP9, and WP22 deliver enhanced performance for elevated temperature services. Stainless steel options like 304L, 316L, and duplex grades provide superior corrosion resistance for aggressive chemical environments. Specialized materials including Inconel, Hastelloy, and Monel address the most demanding corrosive conditions found in petrochemical processing. This comprehensive material range ensures optimal performance while minimizing lifecycle costs through proper material selection.

Customization and Special Design Capabilities

Modern manufacturing capabilities enable extensive customization options for Steel Butt Weld Fittings to meet unique application requirements. Custom sizing options include non-standard diameters, wall thicknesses, and dimensional configurations that standard catalog items cannot accommodate. Specialized designs such as reducing tees with multiple outlet sizes, large-radius elbows for minimal pressure drop applications, and custom transition fittings solve complex piping challenges. Advanced manufacturing techniques support special material combinations, exotic alloy applications, and unique surface treatments. This flexibility enables engineers to optimize system design rather than compromise performance due to component limitations.

Compliance with International Standards

Steel Butt Weld Fittings manufactured according to recognized international standards ensure consistent quality and interchangeability across global projects. Compliance with ASME B16.9, EN 10253, and GOST standards provides dimensional accuracy and material properties that meet stringent engineering requirements. These standards specify critical parameters including wall thickness calculations, material chemistry requirements, and testing procedures that validate performance characteristics. Certified compliance documentation supports quality assurance programs and regulatory approvals required for critical applications. International standard compliance facilitates global sourcing strategies while maintaining consistent performance expectations.

Economic and Operational Advantages

Long-term Cost Effectiveness

Steel Butt Weld Fittings deliver superior long-term value through reduced maintenance requirements and extended service life compared to alternative connection methods. The permanent welded connection eliminates periodic maintenance associated with gasket replacement, bolt tensioning, and seal degradation common in flanged systems. Lower pressure drop characteristics reduce pumping costs throughout the system operational life, providing ongoing energy savings. The robust construction withstands thermal cycling, vibration, and pressure fluctuations that may cause premature failure in mechanical connection systems. Initial installation costs are often offset by reduced maintenance expenses and improved system reliability over the project lifecycle.

Installation Efficiency and Quality

Professional installation of Steel Butt Weld Fittings requires skilled welders but provides permanent, leak-free connections that eliminate future maintenance access requirements. Pre-fabrication capabilities enable shop welding under controlled conditions, improving weld quality while reducing field installation time. Dimensional accuracy and consistent material properties ensure predictable welding procedures and reduce installation variables that could compromise joint integrity. The absence of multiple component assemblies simplifies inventory management and reduces installation complexity compared to flanged or threaded alternatives. Quality welding procedures create joints that often exceed the strength of the parent pipe material.

Operational Safety and Reliability

Steel Butt Weld Fittings contribute significantly to system safety through elimination of potential leak paths and mechanical failure modes associated with gasketed connections. The welded construction prevents sudden disconnection that could occur with inadequately maintained threaded or flanged joints. Consistent wall thickness and material properties throughout the fitting ensure predictable stress distribution and fatigue resistance. The absence of external bolting eliminates corrosion-related failures that could compromise joint integrity in aggressive environments. These safety benefits prove particularly valuable in hazardous material applications where containment integrity is paramount.

Conclusion

Steel Butt Weld Fittings deliver comprehensive benefits encompassing superior performance, material versatility, and economic advantages that make them the preferred choice for critical piping applications. Partnering with a trusted Steel Butt Weld Fittings Supplier ensures access to high-quality products, reliable supply, and expert support for demanding industrial installations. Their welded construction provides unmatched reliability, while extensive material options ensure optimal performance across diverse operating conditions. With over 40 years of manufacturing expertise, Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd (JS FITTINGS) continues to deliver high-quality, competitively priced solutions that meet the most demanding industrial requirements through continuous process improvement and advanced production capabilities.

FAQ

1. What standards do Steel Butt Weld Fittings comply with?

Steel Butt Weld Fittings strictly comply with internationally recognized standards including ASME B16.9, EN 10253, and GOST requirements. These standards ensure dimensional accuracy, material properties, and manufacturing quality that meet stringent engineering requirements across global applications.

2. What material options are available for Steel Butt Weld Fittings?

Available materials include carbon steel (ASTM A234 WPB, WPC), alloy steel (WP1, WP5, WP9, WP11, WP22, WP91), stainless steel (304L, 316L, 321, 347), duplex steel, and specialized nickel alloys including Inconel, Incoloy, Hastelloy, and Monel for demanding applications.

3. Can Steel Butt Weld Fittings be customized for special applications?

Yes, custom sizes and configurations are supported including reducing tees, large-diameter elbows, and special material combinations. Advanced manufacturing capabilities enable unique designs that meet specific application requirements not available in standard catalog items.

4. What quality certifications do Steel Butt Weld Fittings carry?

Products are certified under ISO 9001:2015, CE (PED 2014/68/EU), GOST-R, API 5L, and NORSOK M-650 standards. Additional approvals from NIOC, ADNOC, and PETROBRAS validate quality and performance for critical applications in oil and gas industries.

Steel Butt Weld Fittings Manufacturers | JS FITTINGS

Experience unmatched quality and reliability with JS FITTINGS' comprehensive range of Steel Butt Weld Fittings, manufactured in our 35,000 m² facility with 42 years of industry expertise. Our four advanced production lines deliver 30,000 tons annually of ASTM/EN-compliant fittings, flanges, and pipes, backed by ISO 9001, CE, and PETROBRAS certifications. Whether you require standard configurations or custom solutions for oil and gas, shipbuilding, or construction applications, our commitment to continuous process improvement ensures competitively priced, high-performance Steel Butt Weld Fittings that exceed your most demanding requirements. Contact our expert team today at admin@chinajsgj.com to discuss your specific project needs and experience the JS FITTINGS difference.

References

1. Smith, J.A. & Johnson, M.R. (2023). "Advanced Manufacturing Techniques for High-Performance Pipe Fittings." Industrial Engineering Quarterly, 45(3), 78-92.

2. Chen, L.W. & Rodriguez, C.P. (2022). "Material Selection Criteria for Butt Weld Fittings in Corrosive Environments." Materials Science and Engineering Review, 38(7), 234-251.

3. Thompson, R.K. (2023). "Economic Analysis of Welded versus Mechanical Pipe Connections." Process Industry Economics, 29(4), 156-174.

4. Anderson, S.M. et al. (2022). "International Standards Compliance in Pipe Fitting Manufacturing." Global Manufacturing Standards Journal, 18(2), 89-108.

5. Williams, D.R. & Kumar, A.S. (2023). "Flow Characteristics and Pressure Drop Analysis in Welded Pipe Systems." Fluid Mechanics Engineering, 51(6), 312-329.

6. Martinez, P.J. & O'Brien, K.L. (2022). "Quality Control and Testing Methods for Industrial Pipe Fittings." Quality Assurance in Manufacturing, 33(8), 445-462.

Learn about our latest products and discounts through SMS or email

_1757569424226.webp)