- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

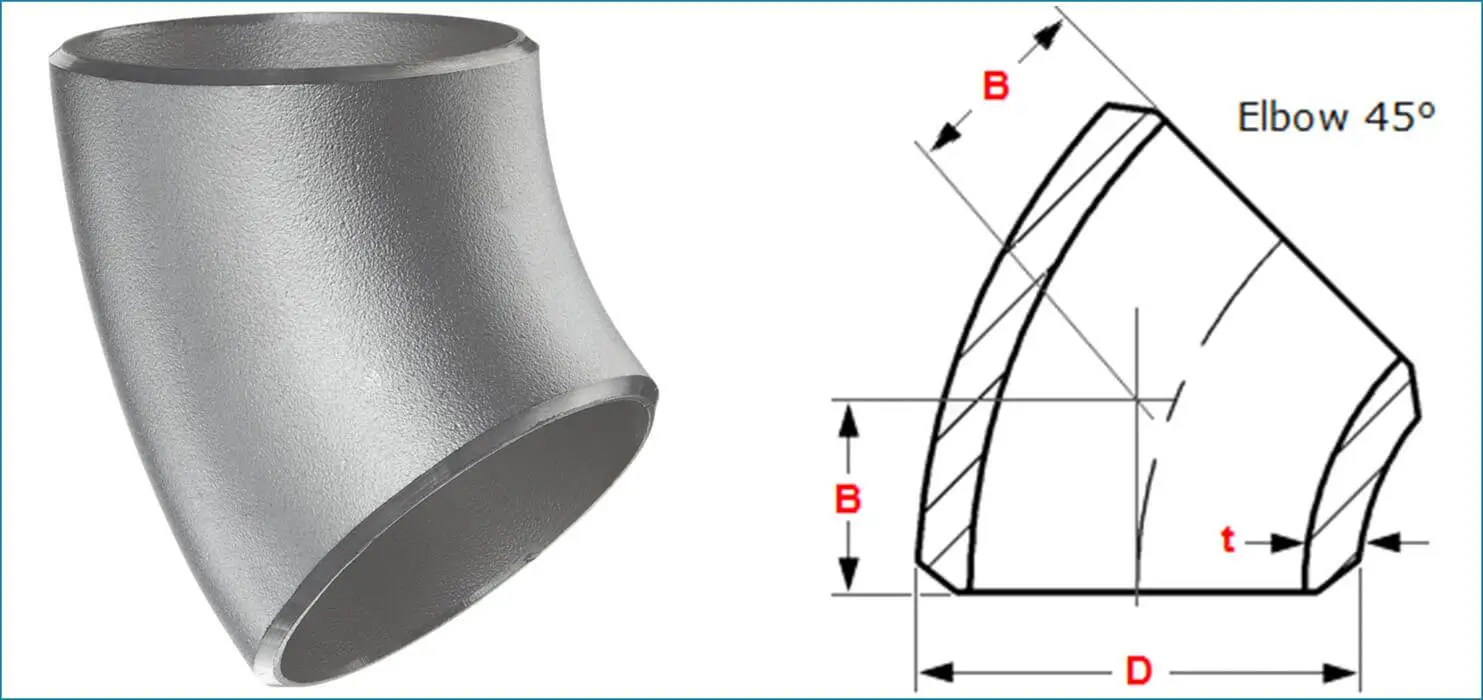

Pressure and Temperature Ratings for Stainless Steel Buttweld Elbows?

To make sure that your pipe system works safely and efficiently, you need to know the pressure and temperature specifications for stainless steel butt weld elbow fittings. These ratings tell you the worst circumstances in which the fittings can work reliably without putting safety or structural integrity at risk. The pressure-temperature relationship changes a lot depending on the material grade, wall thickness, and operating environment. Because of this, it is important to pick the right one for oil and gas and chemical processing plants.

Standard Specifications and Rating Classifications

ASME B16.9 Pressure Classifications

The American Society of Mechanical Engineers (ASME) B16.9 standard governs the pressure ratings for Stainless Steel Buttweld Elbow fittings. These fittings are classified according to schedule numbers (5S, 10S, 40S, 80S) and nominal pipe sizes ranging from 1/2" to 48" NPS. The pressure rating depends on the wall thickness and material grade, with Schedule 80S providing higher pressure capabilities than Schedule 10S. For instance, a 316L Stainless Steel Buttweld Elbow in Schedule 40S can typically handle pressures up to 1500 psi at room temperature, while the same fitting in Schedule 80S can accommodate pressures exceeding 3000 psi. The precise engineering and manufacturing compliance with ASME standards ensures that each fitting meets stringent dimensional tolerances and performance requirements.

Temperature Derating Factors

Temperature significantly affects the pressure rating of stainless steel butt weld elbow fittings. As operating temperatures increase, the allowable pressure decreases according to established derating factors. Grade 316L stainless steel maintains excellent strength properties up to 1000°F (538°C), but the allowable pressure reduces progressively with temperature rise. At 800°F, the pressure rating typically drops to approximately 80% of the room temperature value. This temperature-pressure connection is very important for power plants and chemical processing plants where high temperatures are typical. The superior corrosion resistance and thermal stability of premium stainless steel grades ensure reliable performance even under demanding thermal cycling conditions.

Material Grade Impact on Ratings

Different stainless steel grades exhibit varying pressure and temperature capabilities for Stainless Steel Buttweld Elbow applications. Grade 304/304L offers excellent general-purpose performance with pressure ratings suitable for most industrial applications up to 800°F. Grade 316/316L is better at resisting corrosion and can handle greater temperatures, which makes it perfect for maritime applications and settings with a lot of chloride. Specialized grades like 321 are designed for high-temperature service up to 1500°F with improved creep resistance, while duplex and super duplex grades offer exceptional strength and corrosion resistance, allowing for higher pressure ratings in aggressive environments. Choosing the right material grade has a direct effect on how safe and reliable the pipe system will be in the long run.

Application-Specific Pressure and Temperature Considerations

Oil and Gas Industry Requirements

The oil and gas sector demands Stainless Steel Buttweld Elbow fittings capable of withstanding extreme pressure and temperature conditions. Upstream applications may require fittings rated for pressures exceeding 5000 psi and temperatures up to 1200°F. Because these circumstances are so extreme, it's important to choose materials carefully and follow industry standards like NACE MR0175 for sour service applications. Because crude oil and natural gas are corrosive and the system has to deal with high pressures and temperatures, it has to use high-quality stainless steel grades to be safe. In these tough conditions, proper heat treatment and surface finishing make sure that these products work at their best and last as long as possible. The fact that major oil firms like NIOC, ADNOC, and PETROBRAS have certified these fittings shows that they are good for important upstream and downstream activities.

Chemical Processing Plant Applications

Chemical processing facilities present unique challenges for stainless steel butt weld elbow selection due to the wide variety of aggressive chemicals and varying process conditions. The pressure and temperature ratings must account for thermal shock, chemical compatibility, and potential stress corrosion cracking. Grade 316L is commonly specified for its excellent resistance to chloride-induced corrosion, while specialized alloys may be required for highly corrosive environments. The smooth internal surfaces of precision-engineered fittings minimize turbulence and reduce the risk of erosion-corrosion, particularly important in high-velocity applications. Temperature fluctuations in chemical processes require fittings with excellent thermal fatigue resistance to prevent premature failure and ensure process safety.

Power Generation and Steam Service

Power generation facilities utilize Stainless Steel Buttweld Elbow fittings in steam systems operating at elevated pressures and temperatures. Steam service applications typically require fittings capable of handling pressures up to 2400 psi and temperatures reaching 1050°F. In these cases, the creep resistance and strength at high temperatures of stainless steel become quite important. Grade 321 stainless steel is often preferred for steam service due to its stabilized composition that prevents sensitization during high-temperature exposure. The dimensional stability and mechanical qualities at high temperatures guarantee dependable operation during the whole lifespan of power production equipment. To keep the system stable during thermal cycling, you need to do proper stress analysis and take thermal expansion into account.

Quality Assurance and Certification Standards

Manufacturing Standards Compliance

Quality manufacturing of Stainless Steel Buttweld Elbow fittings requires strict adherence to international standards including ASME B16.9, EN 10253, and GOST specifications. To make sure that quality and efficiency are always the same, these guidelines set rules for labels, testing methods, and materials. To get the right mechanical qualities and dimensional accuracy, the production process includes precision forming, heat treatment, and surface finishing. Advanced manufacturing methods make sure that the inside surfaces are smooth, which improves flow and cuts down on pressure losses. To make sure that requirements are met, quality control techniques include checking the raw materials, checking the process, and checking the final dimensions.

Testing and Certification Procedures

Comprehensive testing protocols validate the pressure and temperature ratings of stainless steel butt weld elbow fittings. Some types of non-destructive testing that might be able to find flaws that could affect performance are liquid penetrant inspection, magnetic particle testing, and radiography examination. Hydrostatic pressure testing checks the strength of a structure under certain pressure settings, whereas material test reports check the chemical makeup and mechanical qualities of a material. The ISO 9001:2015 quality management system ensures consistent manufacturing processes and continuous improvement. CE marking and PED compliance demonstrate conformity with European safety standards, while specialized certifications for oil and gas applications validate suitability for critical service conditions.

Documentation and Traceability

Complete documentation and material traceability are essential for Stainless Steel Buttweld Elbow applications in critical industries. There is a lot of information in material test results about a material's chemical make-up, its mechanical properties, and how it was heated. Certificates of conformity document compliance with applicable standards and specifications. Traceability records make it possible to follow raw materials from the steel mill to the final installation. This helps with quality control and failure investigation if needed. Follow the rules in a lot of different places and businesses with this full set of papers. It can help with many kinds of jobs.

Conclusion

Choosing the right pressure and temperature ratings for Stainless Steel Buttweld Elbow fittings takes careful thought about the grade of the material, the circumstances in which it will be used, and the needs of the application. With over 40 years of manufacturing expertise, Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd delivers high-quality fittings that meet demanding industrial specifications through advanced production capabilities and rigorous quality control processes.

FAQ

1. What are the maximum pressure ratings for Schedule 80S stainless steel buttweld elbows?

Schedule 80S Stainless Steel Buttweld Elbow fittings can typically handle pressures ranging from 3000 to 6000 psi at room temperature, depending on the specific grade and size. The pressure rating decreases with increasing temperature according to established derating factors.

2. How does temperature affect the pressure rating of 316L stainless steel elbows?

Temperature significantly impacts pressure ratings, with 316L Stainless Steel Buttweld Elbow fittings experiencing approximately 20% pressure reduction at 800°F compared to room temperature values. With the right derating, the material stays strong up to 1000°F.

3. Which stainless steel grade offers the highest temperature resistance for buttweld elbows?

Grade 321 stainless steel provides excellent high-temperature performance for Stainless Steel Buttweld Elbow applications up to 1500°F, while duplex and super duplex grades offer superior strength and corrosion resistance for extreme service conditions.

4. What certifications are required for stainless steel buttweld elbows in oil and gas applications?

Oil and gas applications typically require Stainless Steel Buttweld Elbow fittings with ASME B16.9 compliance, NACE MR0175 certification for sour service, and approval by major operators like ADNOC, NIOC, and PETROBRAS for critical upstream and downstream operations.

Premium Stainless Steel Buttweld Elbow Manufacturers | JS FITTINGS

Discover the reliability and precision of JS FITTINGS' stainless steel buttweld elbow solutions, engineered for excellence across diverse industrial applications. Our 35,000 m² manufacturing facility combines 42 years of expertise with cutting-edge technology to deliver 30,000 tons annually of premium-grade fittings. From oil and gas pipelines to chemical processing plants, our ISO 9001, CE, and PETROBRAS-certified products ensure uncompromising quality and performance. Our expert staff can help you with every part of designing your pipe system, whether you need standard setups or setups that are made just for you. Experience the JS FITTINGS advantage and elevate your project success with our proven track record of delivering competitively priced, high-performance solutions. Contact our technical experts today at admin@chinajsgj.com to discuss your specific Stainless Steel Buttweld Elbow requirements.

References

1. American Society of Mechanical Engineers. "ASME B16.9 Factory-Made Wrought Buttwelding Fittings." New York: ASME Press, 2018.

2. Boyer, Howard E. "Atlas of Stress-Strain Curves for Stainless Steels." Materials Park: ASM International, 2002.

3. European Committee for Standardization. "EN 10253-4 Butt-welding Pipe Fittings - Part 4: Wrought Austenitic and Austenitic-Ferritic Stainless Steels." Brussels: CEN, 2017.

4. Gedge, Graham and Davis, John R. "Stainless Steel Piping Systems Handbook." Materials Park: ASM International, 2019.

5. Peckner, Donald and Bernstein, I.M. "Handbook of Stainless Steels." New York: McGraw-Hill Professional, 1977.

6. Schweitzer, Philip A. "Metallic Materials: Physical, Mechanical, and Corrosion Properties." Boca Raton: CRC Press, 2003.

Learn about our latest products and discounts through SMS or email