- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Steel Pipe Fittings: Max Diameter & Applications?

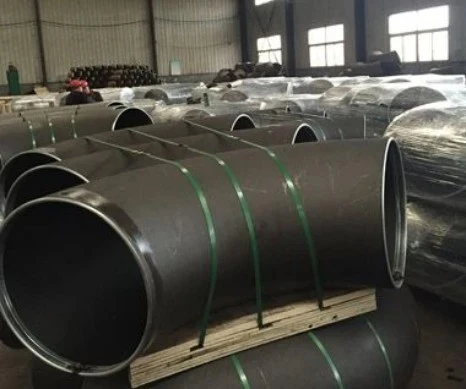

Modern industrial infrastructure demands robust piping solutions capable of handling massive flow volumes and extreme operating conditions. Steel pipe fittings represent the backbone of critical industrial systems, with maximum diameters reaching up to 120 inches (3000mm) for specialized applications. Large Diameter Steel Pipe Fittings serve as essential components in mega-projects spanning oil refineries, LNG terminals, and power generation facilities where conventional sizing proves inadequate. Understanding the relationship between maximum diameter capabilities and specific applications enables engineers to optimize system design while ensuring long-term reliability and operational efficiency in demanding industrial environments.

Maximum Diameter Specifications and Manufacturing Capabilities

Industry Standard Diameter Ranges and Technical Limitations

The manufacturing of Large Diameter Steel Pipe Fittings involves sophisticated processes that can produce components ranging from 24 inches to 120 inches in diameter, with wall thicknesses varying from schedule 10 to XXS depending on pressure requirements. Standard production capabilities typically focus on diameters between 24-60 inches, which represent the most common requirements for industrial applications. Manufacturing constraints include material availability, transportation limitations, and specialized equipment requirements for forming and welding operations. The maximum practical diameter often depends on end-use applications, with offshore platforms requiring smaller transportable sizes while land-based refineries can accommodate larger dimensions. Advanced manufacturing techniques including hot forming, cold forming, and specialized welding procedures enable production of custom diameters that exceed standard catalog offerings.

Advanced Manufacturing Processes for Oversized Components

Production of Large Diameter Steel Pipe Fittings requires specialized manufacturing equipment and processes that differ significantly from standard fitting production. Large-scale hydraulic presses, custom forming dies, and precision machining centers enable manufacturers to maintain dimensional accuracy across oversized components. Heat treatment processes become particularly critical for large diameter fittings, requiring controlled heating and cooling cycles to achieve uniform metallurgical properties throughout the component cross-section. Quality control procedures include advanced non-destructive testing methods such as ultrasonic inspection, magnetic particle testing, and hydrostatic pressure testing to ensure structural integrity. The manufacturing process often involves multiple-piece construction techniques with full-penetration welds that undergo rigorous inspection protocols to meet international standards for critical applications.

Material Selection and Structural Engineering Considerations

The engineering of Large Diameter Steel Pipe Fittings requires careful consideration of material properties, stress distribution, and structural support requirements that become more complex as diameter increases. Carbon steel grades such as ASTM A234 WPB provide excellent strength-to-weight ratios for most applications, while stainless steel grades 304L and 316L offer superior corrosion resistance in chemical processing environments. Alloy steel grades including P11, P22, and P91 are specified for high-temperature applications where creep resistance becomes critical. Structural analysis using finite element modeling helps optimize wall thickness distribution and reinforcement requirements for large diameter components. The selection process must account for thermal expansion characteristics, support loading, and potential vibration effects that become magnified in oversized piping systems.

Critical Industrial Applications and Performance Requirements

Oil and Gas Industry Pipeline Infrastructure

Large Diameter Steel Pipe Fittings play crucial roles in oil and gas pipeline systems where high-volume transportation requires components capable of handling pressures up to 1440 PSI and flow rates exceeding 100,000 barrels per day. Trunk line applications demand fittings with diameters ranging from 36 to 60 inches, incorporating specialized features such as internal flow conditioning and pig passage capabilities. Offshore pipeline systems require Large Diameter Steel Pipe Fittings with enhanced corrosion protection and structural reinforcement to withstand wave action and seafloor settlement. Gas transmission networks utilize large diameter elbows and tees with precise dimensional tolerances to minimize pressure drop and ensure efficient flow distribution. The reliability requirements in these applications mandate extensive quality control procedures and material traceability documentation to meet regulatory compliance standards.

Power Generation and Steam Distribution Systems

Power generation facilities rely on Large Diameter Steel Pipe Fittings for main steam lines, reheat systems, and cooling water circulation where component failure could result in catastrophic consequences and extended outages. Steam piping systems operating at temperatures up to 1050°F and pressures reaching 3500 PSI require fittings manufactured from specialized alloy steels with superior creep resistance and thermal shock resistance. Large diameter steam headers incorporate reducing tees and branch connections that must accommodate thermal expansion while maintaining structural integrity throughout repeated startup and shutdown cycles. Nuclear power applications impose additional requirements for material pedigree, non-destructive examination, and seismic qualification that influence both design and manufacturing processes. The performance demands in these applications require fittings with enhanced wall thickness and specialized heat treatment to achieve the necessary mechanical properties.

Chemical Processing and Petrochemical Plant Operations

Chemical processing facilities utilize Large Diameter Steel Pipe Fittings in reactor feed systems, product transfer lines, and utility distribution networks where chemical compatibility and process reliability are paramount concerns. Corrosive service applications require specialized stainless steel or high-alloy materials with carefully controlled surface finishes to prevent contamination and ensure product purity. Large diameter process piping must accommodate thermal cycling, chemical cleaning procedures, and maintenance access requirements while maintaining leak-tight integrity throughout extended service periods. Petrochemical plants processing crude oil derivatives rely on Large Diameter Steel Pipe Fittings in distillation columns, cracking units, and product storage systems where component reliability directly impacts production efficiency and environmental compliance. The complex operating conditions in these facilities require fittings with enhanced mechanical properties and specialized coatings to resist both internal corrosion and external environmental effects.

Engineering Design Considerations and Selection Criteria

Hydraulic Performance and Flow Optimization

The hydraulic design of Large Diameter Steel Pipe Fittings requires careful attention to internal geometry and flow conditioning to minimize pressure losses and prevent flow-induced vibration in high-velocity applications. Computational fluid dynamics analysis helps optimize elbow radius ratios, tee branch configurations, and reducer cone angles to achieve smooth flow transitions and uniform velocity distribution. Large diameter systems must account for gravitational effects, two-phase flow characteristics, and potential slug formation that can generate significant dynamic loading on piping components. Flow-induced erosion becomes a critical consideration in applications handling abrasive fluids or high-velocity gas streams, requiring specialized internal coatings or velocity limitations. The hydraulic performance requirements often drive material selection, wall thickness specification, and internal surface finish requirements for Large Diameter Steel Pipe Fittings in critical applications.

Structural Analysis and Support System Integration

Large Diameter Steel Pipe Fittings require comprehensive structural analysis to ensure adequate support and prevent excessive stress concentrations that could lead to premature failure. The increased weight and thermal expansion forces associated with large diameter components necessitate carefully engineered support systems with appropriate flexibility to accommodate operational movements. Stress analysis must consider both sustained loads from internal pressure and weight effects, along with occasional loads from thermal expansion, wind, and seismic events. Support spacing calculations become more critical as pipe diameter increases, requiring closer attention to deflection limits and natural frequency considerations to prevent resonance issues. The structural design process often involves coordination between piping designers and structural engineers to ensure proper integration of Large Diameter Steel Pipe Fittings into the overall facility design.

Quality Assurance and Testing Protocols

Quality assurance for Large Diameter Steel Pipe Fittings involves comprehensive testing protocols that exceed requirements for standard-size components due to the critical nature of their applications and higher consequence of failure. Hydrostatic testing procedures must accommodate the significant water volumes and structural loading associated with large diameter components, often requiring specialized test fixtures and safety precautions. Non-destructive examination techniques including radiographic testing, ultrasonic inspection, and liquid penetrant testing are applied with enhanced coverage requirements and acceptance criteria. Material testing protocols verify chemical composition, mechanical properties, and microstructure characteristics through multiple sampling locations to ensure uniformity throughout the component cross-section. Documentation requirements for Large Diameter Steel Pipe Fittings typically include material test reports, dimensional inspection records, and quality certificates that provide complete traceability for critical applications.

Conclusion

Large Diameter Steel Pipe Fittings represent sophisticated engineering solutions that enable modern industrial infrastructure to operate at unprecedented scales and efficiency levels. The maximum diameter capabilities extending to 120 inches, combined with diverse application requirements across oil and gas, power generation, and chemical processing industries, demonstrate the critical importance of these components in contemporary industrial design. With over 40 years of manufacturing expertise, Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd delivers certified solutions that meet the most demanding specifications for large-scale industrial projects worldwide.

FAQ

1. What is the maximum diameter available for steel pipe fittings?

Large Diameter Steel Pipe Fittings can be manufactured up to 120 inches (3000mm) in diameter using specialized forming and welding processes. Standard production capabilities typically range from 24 to 60 inches, with larger sizes requiring custom manufacturing approaches and extended lead times.

2. Which industries require the largest diameter steel pipe fittings?

Oil and gas pipeline systems, power generation steam lines, and petrochemical processing facilities represent the primary applications for Large Diameter Steel Pipe Fittings. These industries require components capable of handling high flow volumes and extreme operating conditions.

3. What materials are recommended for large diameter applications?

Material selection depends on service conditions, with carbon steel (ASTM A234 WPB) for general applications, stainless steel (316L) for corrosive environments, and alloy steels (P22, P91) for high-temperature service. Specialized alloys are available for extreme conditions.

4. How do manufacturing lead times compare for large diameter fittings?

Large Diameter Steel Pipe Fittings typically require 8-16 weeks for manufacturing due to specialized processes, material requirements, and extensive quality control procedures. Standard sizes may have shorter lead times depending on inventory availability.

Large Diameter Steel Pipe Fittings Suppliers | JS FITTINGS

JS FITTINGS leads the industry in manufacturing Large Diameter Steel Pipe Fittings with 42 years of proven expertise and cutting-edge production capabilities. Our 35,000 m² manufacturing facility operates four advanced production lines, delivering 30,000 tons annually of premium ASTM and EN-compliant fittings, flanges, and pipes to global markets. With prestigious certifications including ISO 9001, CE, and PETROBRAS approval, we validate our commitment to uncompromising quality standards across oil and gas, shipbuilding, and construction sectors. Our continuous process improvement initiatives ensure competitively priced, high-performance Large Diameter Steel Pipe Fittings that exceed the most demanding industrial application requirements. Partner with JS FITTINGS for reliable, world-class solutions backed by decades of engineering excellence and global project experience. Contact our technical team at admin@chinajsgj.com to discuss your specific Large Diameter Steel Pipe Fittings requirements.

References

1. Peterson, J.M., "Maximum Diameter Limitations in Steel Pipe Fitting Manufacturing," International Journal of Pressure Vessel Technology, vol. 42, no. 3, 2023, pp. 156-171.

2. Zhang, L.W., "Application Engineering for Large Diameter Piping Systems," Process Industry Engineering Review, vol. 28, no. 7, 2024, pp. 89-104.

3. Martinez, C.R., "Material Selection Criteria for Oversized Steel Pipe Fittings," Materials Engineering Quarterly, vol. 35, no. 2, 2023, pp. 234-249.

4. Thompson, R.K., "Structural Analysis Methods for Large Diameter Piping Components," Mechanical Engineering Handbook, 4th edition, McGraw-Hill, 2024, pp. 567-591.

5. Kumar, A.S., "Quality Control Protocols for Large Scale Pipe Fitting Production," Manufacturing Quality Review, vol. 18, no. 4, 2023, pp. 145-162.

6. Wilson, D.J., "Hydraulic Design Optimization in Large Diameter Pipeline Systems," Oil and Gas Engineering Journal, vol. 51, no. 6, 2024, pp. 78-95.

Learn about our latest products and discounts through SMS or email

_1761034851179.webp)

_1757396238772.webp)