- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Schedule Galvanized 40 steel Pipe

2. Dual-standard certified steel pipes | API 5L + EN 10219 dual compliance assurance

3. Precision Cutting Services | Ready-to-use pipe end treatments

4. Oil and Gas Project Logistics System | Exclusive Shipping Solutions Covering Central Asia/Middle East

5. Compliant with International Standards: ASTM、ASME、API 5L/12CT、DIN、EN, ISO、JIS、GOST

Schedule Galvanized 40 Steel Pipe: Durable, Versatile, and Industry-Trusted

At Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd, we're proud to offer top-quality Schedule 40 Galvanized Steel Pipe. With 39 years of manufacturing expertise, we deliver superior products that meet rigorous industry standards. Our Schedule Galvanized 40 steel Pipe combines durability, corrosion resistance, and versatility, making it the go-to choice for various industrial applications.

Key Features

- Superior Corrosion Resistance: Hot-dip galvanization ensures long-lasting protection.

- Uniform Wall Thickness: Consistent strength and reliability throughout the pipe.

- High Pressure Rating: Suitable for demanding industrial environments.

- ASTM A53/A106 Compliant: Meets or exceeds industry standards.

- Versatile Applications: Ideal for water, gas, and oil transport systems.

Product Types

- Seamless Schedule 40 Galvanized Steel Pipe

- Welded Schedule 40 Galvanized Steel Pipe

- Threaded and Coupled Schedule 40 Galvanized Steel Pipe

Materials & Grades

Our product is manufactured using high-quality carbon steel, typically ASTM A53 Grade B or ASTM A106 Grade B. These materials offer:

- Excellent mechanical properties

- High tensile strength

- Good weldability

- Optimal corrosion resistance when galvanized

Surface Treatment

Hot-dip galvanization is our standard surface treatment for Schedule 40 steel pipes. This process involves:

- Thorough cleaning of the steel surface

- Immersion in molten zinc at approximately 450°C (842°F)

- Formation of a zinc-iron alloy layer

- Outer layer of pure zinc for added protection

The result is a durable, corrosion-resistant finish that significantly extends the pipe's lifespan.

Dimensional Tolerance Checks(Per ASTM A530/API 5L)

|

Parameter |

Tolerance |

Instrument Used |

|

Outer Diameter(OD) |

±1%of nominal OD (or±0.79mm) |

Pi tape/Laser micrometer |

|

Wall Thickness(WT) |

±12.5%(SCH40 and below) |

Ultrasonic thickness gauge(UTG) |

|

Length |

±3mm for random,±6mm for cut-length |

Calibrated tape measure |

|

Straightness |

≤0.2%of total length |

Optical comparator |

|

Bevel Angle (for welding) |

30°-35°(±5°) |

Bevel protractor |

Visual &Surface Inspection

·Defect Identification:

o Lamination- Check for delamination near pipe ends

o Scratches/Dents -Max 5%of WT depth allowed (per ASME B31.3)

o Rust &Mill Scale-Controlled by SSPC-SP6(Commercial Blast Cleaning)

● Method:

o White light inspection(10,000 lux minimum)

o Dye penetrant test(PT)for surface cracks

Applications

Our versatile Schedule Galvanized 40 steel Pipe finds use in numerous industries:

- Construction: Structural support and framework

- Oil & Gas: Transportation of petroleum products

- Water Treatment: Municipal water systems and irrigation

- Fire Protection: Sprinkler systems and hydrant supply lines

- HVAC: Ventilation and air conditioning systems

- Agricultural: Irrigation and livestock watering systems

- Manufacturing: Process piping and equipment fabrication

Packaging & Delivery

We understand the importance of safe transportation for our products. Our packaging options include:

- Bundle packaging with steel strips

- Wooden crates for added protection

- Custom packaging solutions for specific requirements

Our dedicated logistics network ensures timely delivery, whether you're ordering locally or internationally.

Quality Control

At Hebei Jinsheng, quality is our top priority. Our rigorous quality control process includes:

- Raw material inspection

- In-process checks during manufacturing

- Dimensional accuracy verification

- Hydrostatic pressure testing

- Galvanization thickness measurement

- Visual and ultrasonic inspections

These measures guarantee that every product meets our high standards and your specific requirements.

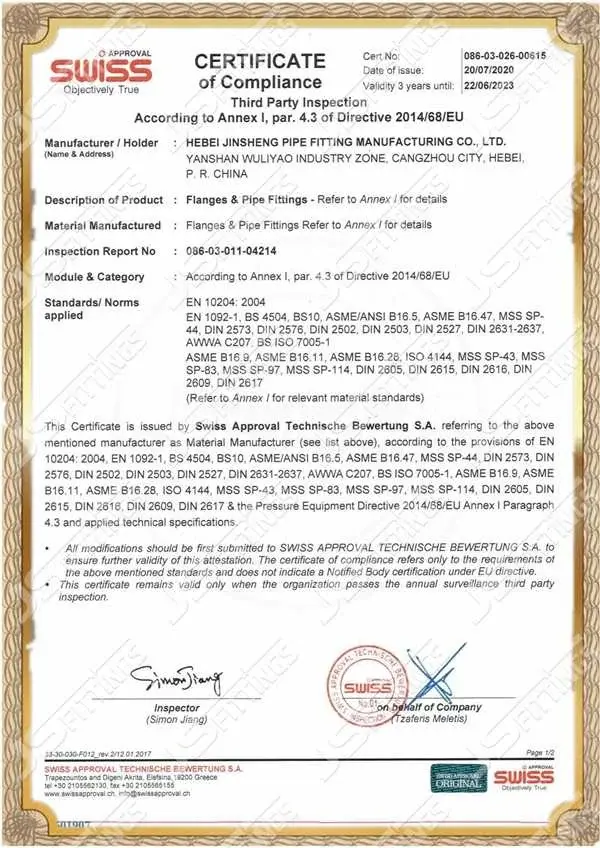

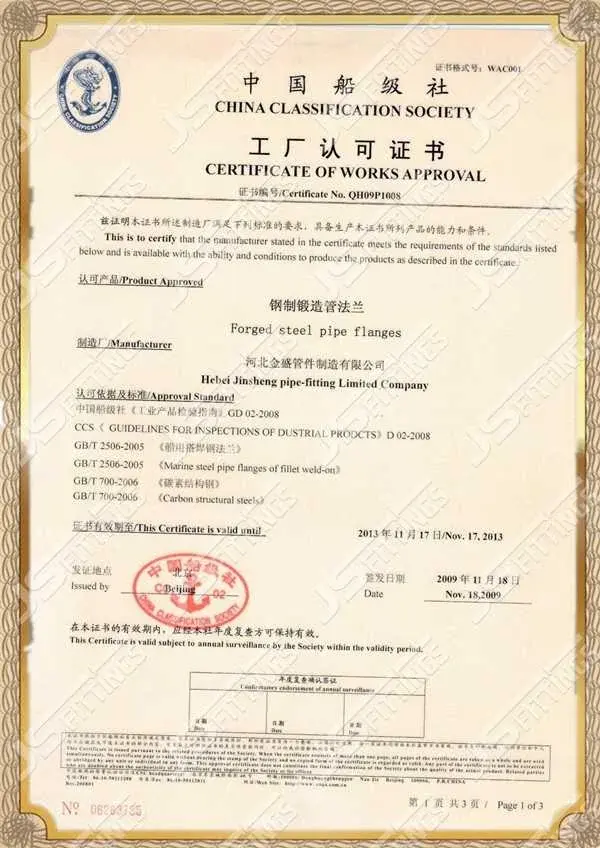

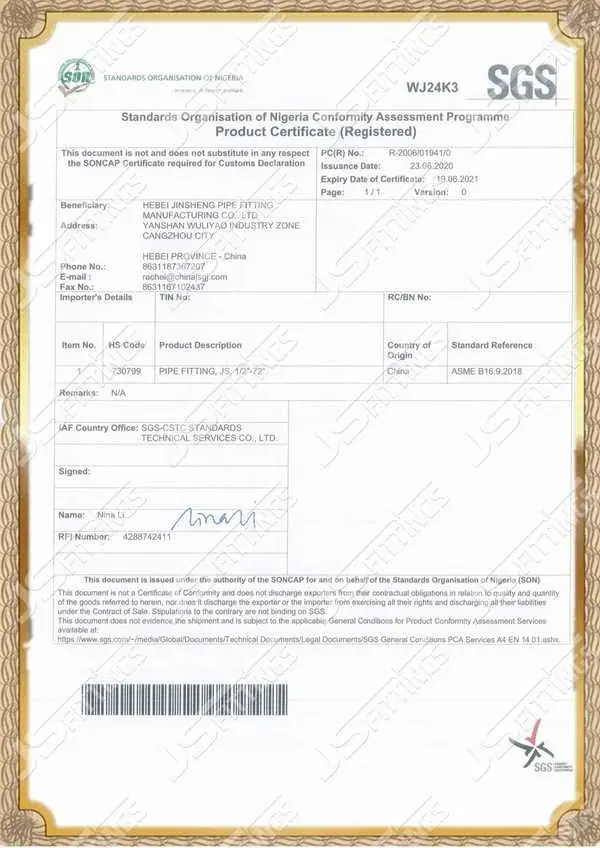

Certificates

Our commitment to quality is backed by international certifications:

- ISO 9001:2015 Quality Management System

- CE Marking for European market compliance

- GOST-R certification for Russian market access

- API 5L certification for oil and gas industry standards

These certifications demonstrate our dedication to producing reliable, high-quality products that meet global standards.

FAQ

Q: What is the standard length for Schedule 40 Galvanized Steel Pipe?

A: Standard lengths are typically 6 meters (20 feet) or 12 meters (40 feet), but custom lengths are available upon request.

Q: Can Schedule 40 Galvanized Steel Pipe be used for drinking water systems?

A: Yes, our pipes are suitable for potable water systems when properly installed and maintained.

Q: What is the temperature range for Schedule 40 Galvanized Steel Pipe?

A: These pipes can typically withstand temperatures from -20°C to 350°C (-4°F to 662°F), depending on the specific application and pressure requirements.

Q: How long does the galvanization process extend the pipe's lifespan?

A: Galvanization can extend the pipe's lifespan by 50 years or more, depending on environmental conditions and proper maintenance.

Q: Can you provide custom dimensions for Schedule 40 Galvanized Steel Pipe?

A: Yes, we offer customization services to meet specific project requirements. Contact our sales team for more information.

Contact Us

Ready to elevate your projects with our premium Schedule Galvanized 40 steel Pipe? Our team of experts is here to assist you with product selection, technical support, and custom solutions. Get in touch today to discuss your needs and experience the Hebei Jinsheng difference.

Email: admin@chinajsgj.com

Phone: +8618003119682

Trust Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd for all your Schedule 40 Galvanized Steel Pipe needs. With our commitment to quality, extensive industry experience, and customer-focused approach, we're your reliable partner for durable, high-performance piping solutions.

Learn about our latest products and discounts through SMS or email

_1757576028658.webp)