- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

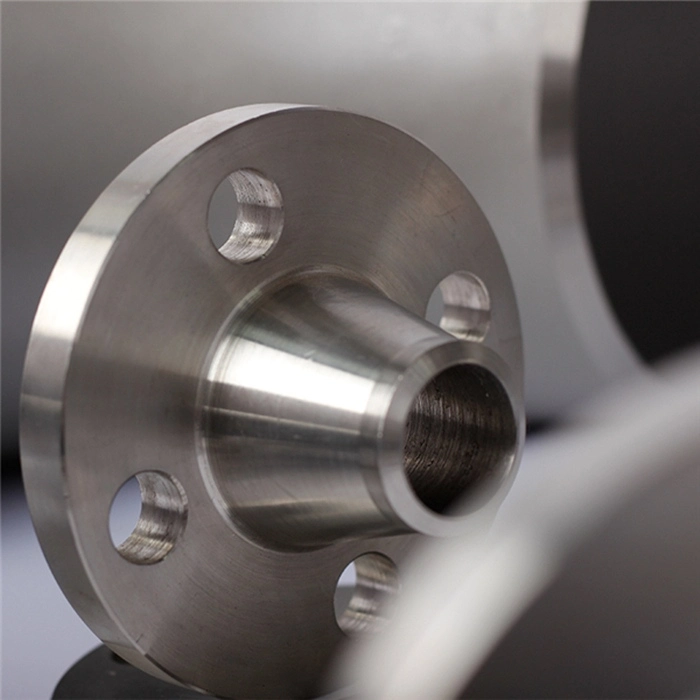

10 Inch Weld Neck Flanges

Class range: Class 150 to 2500(# or LB). PN 2.5 to PN 250.

Flange face type: RF (Raised Face), RTJ (Ring Type Joint)

Weld neck flanges, also known as welding neck flanges, are an important part of various industries, providing a strong connection between pipes, valves, and equipment. These specialized flanges have unique features that make them useful in challenging situations.

Types of Weld Neck Flanges

Weld neck flanges come in two main designs:

1. Standard Weld Neck Flanges:

These flanges are used with butt weld fittings, making them a crucial part of many piping systems. They work with various face types and different pressure classes.

2. Long Weld Neck Flanges:

Also called nozzle flanges or “long neck” flanges, these special flanges are mainly designed for pressure vessel and tank fabrication. They act as a one-piece replacement for standard weld neck and pipe weld combinations.

Applications of Weld Neck Flanges

Weld neck flanges are used in situations where conditions are tough. Some common scenarios include:

- High-pressure systems

- Wide temperature and pressure fluctuations

- High-temperature environments

- Handling volatile and hazardous fluids

- Working in very cold conditions

These flanges are built to handle such challenging conditions, thanks to their strong construction and excellent stress distribution capabilities.

Materials of Weld Neck Flanges

Welding neck flanges come in various materials, chosen to meet industry standards and application needs. The material used depends on factors like temperature, pressure, and the type of fluids being transported. Common materials for weld neck flanges include:

- Carbon steel (ASTM A105)

- Alloy steel (ASTM A182, with variations like F11 and F22)

- Stainless steel (ASTM A182, including grades like F304/F304L, F316/F316L)

- Duplex steel (UNS S31803)

- Nickel alloys (e.g., Inconel 600 and 625, Hastelloy C22 and C276)

Standards for Weld Neck Flanges

The manufacturing and usage of weld neck flanges are governed by recognized standards to ensure consistency and safety. Some relevant standards include:

ASTM A105 for carbon steel weld neck flanges

ASTM A182 for alloy and stainless steel weld neck flanges, with variations for different grades

ASME B16.5 for flange dimensions and specifications

ASME B16.47 for large diameter flanges

BS 3293 for British standards

DIN 2630 PN standards for European applications

Frequently Asked Questions (FAQs)

1. What is a Weld Neck Flange?

A Weld Neck Flange, often called a welding neck flange, is a type of flange designed for welding to pipes. It has a long-tapered hub that provides mechanical strength and resistance to deformation.

2. What are the Main Types of Weld Neck Flanges?

There are two primary types: Standard Weld Neck Flanges, used with butt weld fittings, and Long Weld Neck Flanges, designed for pressure vessels and tanks.

3. Where are Weld Neck Flanges Commonly Used?

Weld Neck Flanges are ideal for applications with challenging conditions, such as high pressure, extreme temperatures, volatile fluids, or sub-zero environments.

4. What Materials are Weld Neck Flanges Made From?

Weld Neck Flanges can be crafted from various materials, including carbon steel, alloy steel (e.g., ASTM A182 F11, F22), stainless steel (e.g., ASTM A182 F304/F304L, F316/F316L), and nickel alloys (e.g., Inconel 600, Hastelloy C22).

5. What Are the Common Dimensions and Sizes of Weld Neck Flanges?

Weld Neck Flanges are available in a wide range of sizes, with dimensions tailored to match pipe inside diameters. For example, a 1/2″ NPS weld neck flange has an inside diameter of 0.62″ and an outside diameter of 3.50″.

6. What Pressure Classes Are Available for Weld Neck Flanges?

Weld Neck Flanges come in various pressure classes, including Class 150, 300, 400, 600, 900, 1500, and 2500, as well as PN 2.5 to PN 250.

7. What Are the Common Face Types for Weld Neck Flanges?

Common face types include Raised Face (RF) and Ring Type Joint (RTJ). RF flanges have a small raised portion surrounding the bore, while RTJ flanges have a special groove for metal gasket seating.

8. What Standards Govern the Use of Weld Neck Flanges?

Weld Neck Flanges adhere to industry standards such as ASTM A105 for carbon steel, ASTM A182 for alloy and stainless steel, ASME B16.5 for dimensions, ASME B16.47 for large diameter flanges, BS 3293, and DIN 2630 PN standards.

9. How Are Weld Neck Flanges Tested for Quality?

Non-Destructive Testing (NDT) techniques like phased array, magnetic particle inspection, dye penetrant inspection, radiographic testing, and ultrasonic testing are employed to ensure weld integrity and detect internal damage on sealing faces.

10. Why Choose Weld Neck Flanges Despite Higher Costs?

Weld Neck Flanges may come at a higher cost, but they offer superior reliability and safety, making them an essential choice for demanding applications where performance is critical.

Contact Us

Ready to elevate your industrial projects with our premium steel weld neck flanges? Our team of experts is here to assist you.

Email: admin@chinajsgj.com

Phone: +8618003119682

Trust Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd for all your product needs. With our commitment to quality, competitive pricing, and customer satisfaction, we're your ideal partner for industrial piping solutions.

Learn about our latest products and discounts through SMS or email

_1761292428702.webp)