- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Stainless Steel Blind Flange

Type: Blind Flange

Size Ranges: From 1/2 inch (i.e. 15 NB) upto 48 inch (i.e. 1200NB)

Standards: ASME | BS | DIN | ANSI | GOST | EN Flanges

JIS Standards: 5 K, 10K, 16K, 20 K, 30K, 40K, 63 K

Pressure Classes: Cl 150, Class 300, Cl. 400, 600, Class 900, Cl 1500 and 2500

EN Standard: 6Bar, 10 Bar, 16Bar, 25 Bar, 40Bar

Blind flanges are an essential component in various industrial piping systems, and our stainless steel blind flanges offer superior performance and reliability. Crafted from high-quality stainless steel, these flanges are designed to seal off pipe ends, providing a secure and leak-proof closure.

What are Blind Flanges?

Unlike other flange types that connect two sections of pipe, a blind flange serves as a blanking plate, effectively terminating a pipeline or vessel opening. This makes them ideal for isolating sections of a system for maintenance, repair, or future expansion.

The Advantage of Stainless Steel in blind flanges:

Our blind flanges are manufactured from premium stainless steel, a material renowned for its exceptional properties:

Corrosion Resistance: Stainless steel offers excellent resistance to a wide range of corrosive media, making it suitable for harsh environments in Chemical, petrochemical, and marine applications.

High Strength and Durability: Forged stainless steel provides superior hardness, toughness, and resistance to wear and tear, ensuring a long service life even under demanding conditions.

Temperature Resistance: Stainless steel maintains its integrity and performance across a broad spectrum of temperatures, from cryogenic to high-heat applications.

Hygienic Properties: The smooth, non-porous surface of stainless steel is easy to clean and sanitize, making it a preferred choice for pharmaceutical and food processing industries.

Applications Across Industries

The versatility and robust nature of stainless steel blind flanges make them indispensable in numerous sectors:

Oil & Gas: Used in pipelines, drilling equipment, and refining facilities to safely isolate sections.

Chemical & Petrochemical: Ideal for highly corrosive environments where chemical resistance is paramount.

Pharmaceutical: Ensures a sterile and contamination-free seal in drug manufacturing processes.

Marine: Excellent resistance to saltwater corrosion makes them perfect for shipbuilding and offshore platforms.

Water Treatment: Provides reliable sealing in municipal and industrial water processing plants.

Understanding Material Grades

The performance characteristics of a flange are largely determined by its material grade. Different grades of stainless steel offer varying mechanical properties, including tensile strength, yield strength, and temperature limits. We offer a range of material grades to meet the specific requirements of your application, ensuring optimal performance and safety.

Packaging & Delivery

We ensure secure packaging to protect your products during transit:

Wooden cases or pallets

Bubble wrap and plastic film protection

Custom packaging solutions available

Our dedicated logistics network guarantees timely delivery of bulk orders worldwide.

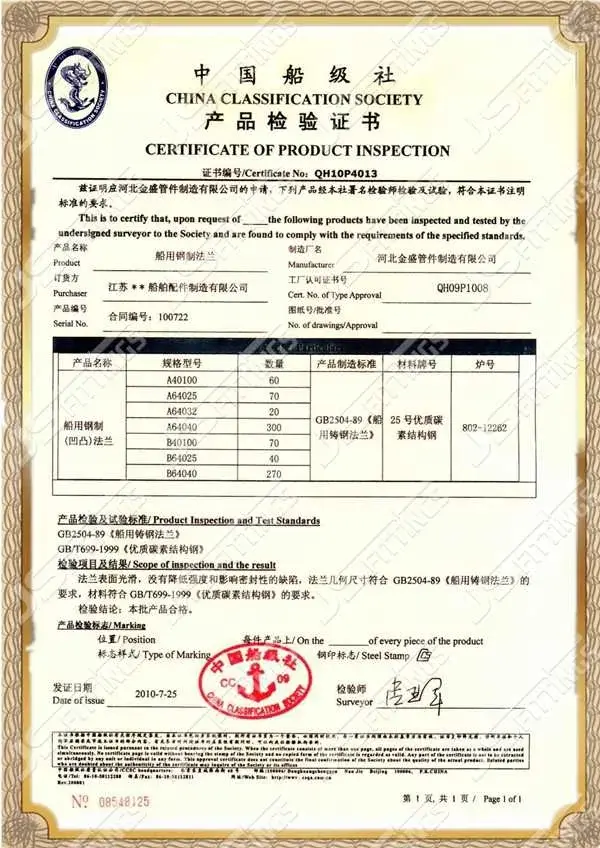

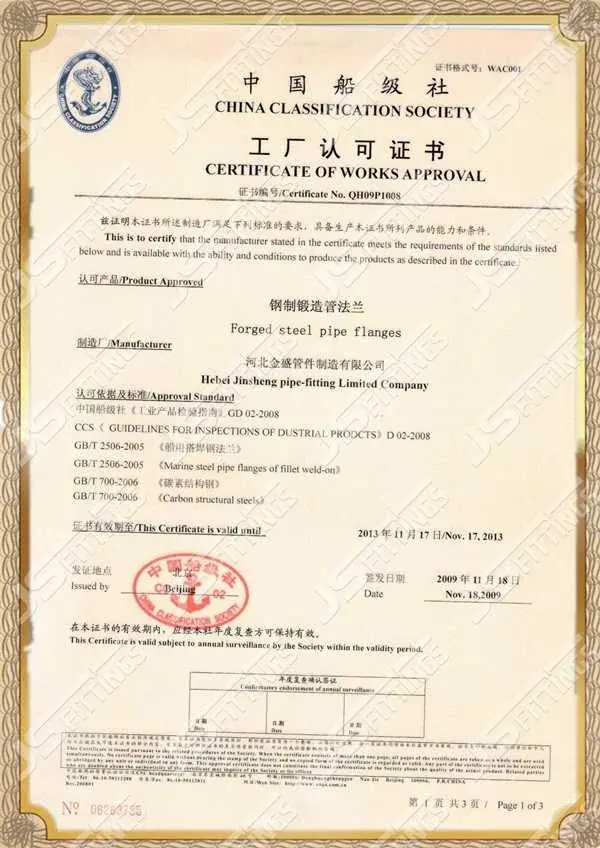

Quality Control

At Hebei Jinsheng, quality is paramount. Our products undergo rigorous testing:

Material composition analysis

Dimensional checks

Hydrostatic pressure tests

Non-destructive examinations (NDT)

Visual inspections

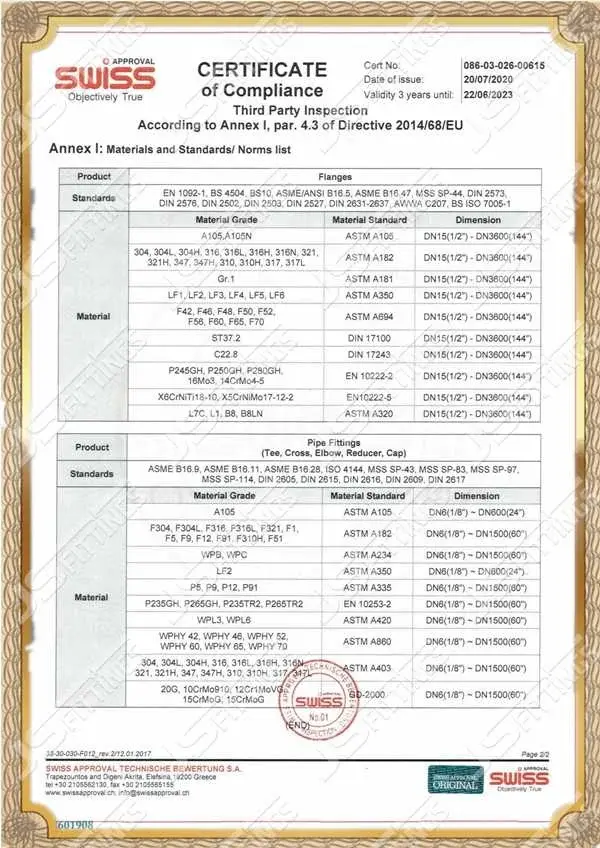

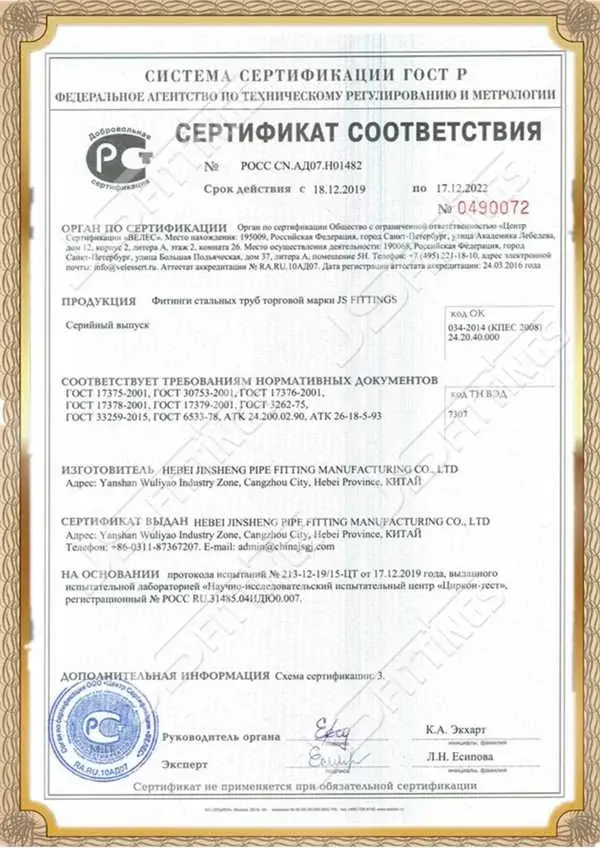

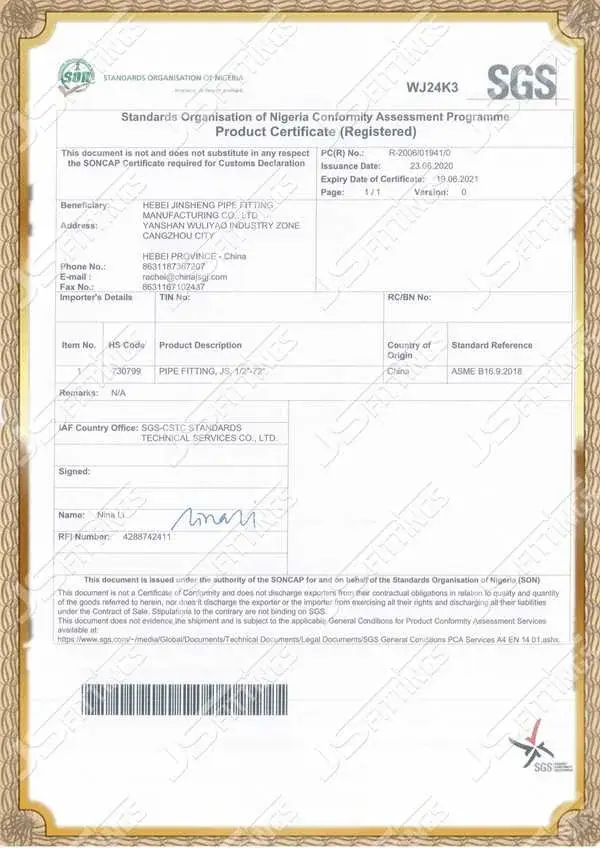

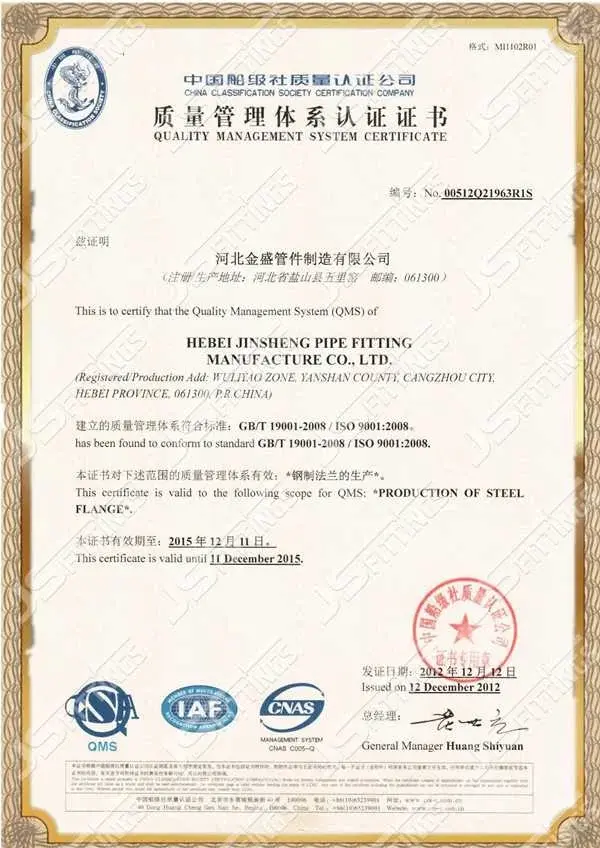

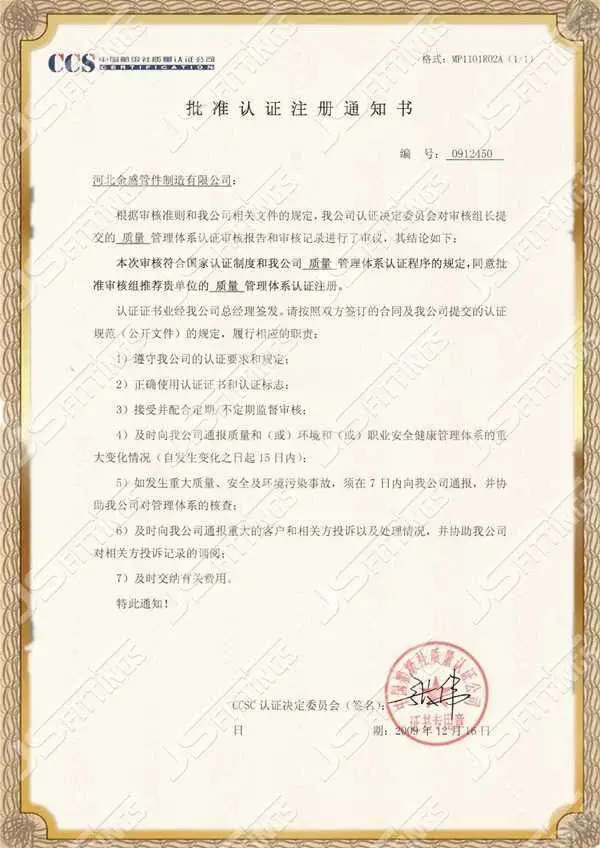

Certificates

Our commitment to quality is backed by international certifications:

ISO 9001:2015

CE Marking

GOST-R

API Spec Q1

PED 2014/68/EU

FAQ

Q: What is the minimum order quantity for the products?

A: We typically accommodate orders starting from 100 pieces, but we're flexible based on your project needs.

Q: Can you provide custom products?

A: Yes, we offer customization services to meet your specific requirements. Contact our team for details.

Q: What is the lead time for bulk orders?

A: Lead times vary based on order size and specifications. Generally, we aim for 15-30 days for standard products.

Q: Do you provide material test reports (MTR)?

A: Yes, we provide comprehensive MTRs with every shipment to ensure full traceability.

For reliable, long-lasting, and high-performance piping solutions, look no further.

For a customized quote or to discuss your specific requirements, please contact us today!

Email: admin@chinajsgj.com

Phone: +8618003119682

Learn about our latest products and discounts through SMS or email