Material Science Behind Seamless Technology

The superior performance of seamless butt weld fittings is deeply rooted in the material science and manufacturing processes used to create them. Understanding these aspects helps appreciate why these fittings are often the go-to choice for critical applications.

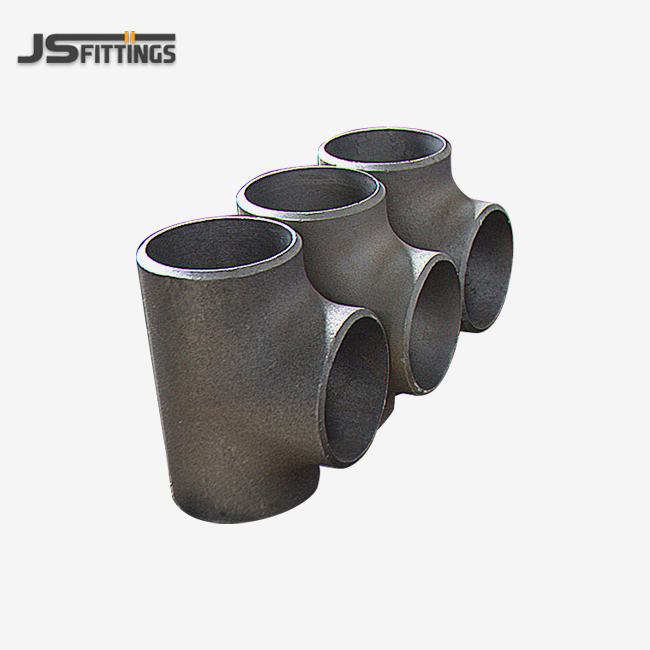

Manufacturing Process

Seamless butt weld fittings are typically produced through a process called hot working. This involves heating a solid billet of metal to high temperatures and then using specialized machinery to pierce and shape it into the desired form. This method ensures that the fitting maintains a uniform grain structure throughout, contributing to its overall strength and durability.

The absence of weld seams in seamless fittings eliminates potential weak points that could be susceptible to stress concentration or corrosion. This seamless construction results in a more homogeneous material structure, which is particularly beneficial in applications involving high pressures, extreme temperatures, or corrosive environments.

Material Selection

The choice of material for seamless butt weld steel pipe fittings is crucial and depends on the specific requirements of the application. Common materials include:

- Carbon Steel: Offers good strength and ductility at a competitive cost.

- Alloy Steel: Provides enhanced strength and heat resistance for more demanding applications.

- Stainless Steel: Offers excellent corrosion resistance and is ideal for use in chemical processing and food industries.

Each material brings its own set of properties, allowing engineers to select the most suitable option for their specific project needs. The seamless construction further enhances these inherent material properties, resulting in fittings that can withstand extreme conditions more effectively than their welded counterparts.

Cost-Benefit Analysis: Long-Term Savings Explained

While the initial cost of seamless butt weld fittings may be higher compared to welded alternatives, a comprehensive cost-benefit analysis reveals significant long-term savings. This section explores the economic advantages of choosing seamless fittings for construction projects.

Reduced Maintenance and Downtime

One of the primary benefits of using seamless butt weld steel pipe fittings is the reduction in maintenance requirements and associated downtime. The robust, uniform construction of seamless fittings makes them less prone to issues such as stress cracking, corrosion at weld points, or fatigue failure. This translates to:

- Fewer inspections and repairs

- Extended intervals between maintenance shutdowns

- Reduced risk of unexpected failures and emergency repairs

For industrial facilities where downtime can cost thousands of dollars per hour, the reliability offered by seamless fittings can result in substantial savings over the life of the system.

Extended Service Life

Seamless butt weld fittings typically offer a longer service life compared to welded alternatives. This longevity is attributed to:

- Higher resistance to cyclic loading and fatigue

- Better performance under extreme temperatures and pressures

- Improved resistance to corrosion and erosion

A longer service life means less frequent replacements, reducing both material costs and the labor expenses associated with system upgrades or overhauls. This extended lifespan is particularly valuable in industries where piping systems are expected to operate reliably for decades.

Energy Efficiency

The smooth internal surface of seamless fittings contributes to improved flow characteristics within the piping system. This can lead to:

- Reduced pumping energy requirements

- Lower pressure drops across the system

- Improved overall system efficiency

Over time, these efficiency gains can result in significant energy savings, particularly in large-scale industrial applications where even small improvements in flow efficiency can translate to substantial cost reductions.

Expert Tips: Proper Installation Techniques

To fully leverage the advantages of seamless butt weld fittings, proper installation is crucial. This section provides expert insights on installation techniques to ensure optimal performance and longevity of your piping system.

Preparation and Alignment

Proper preparation and alignment are fundamental to achieving a high-quality butt weld joint:

- Clean the pipe and fitting ends thoroughly to remove any contaminants

- Use precision cutting tools to ensure square end cuts

- Employ alignment clamps or jigs to maintain proper positioning during welding

- Verify that the pipe and fitting materials are compatible and meet project specifications

Accurate alignment not only facilitates a stronger weld but also helps maintain the integrity of the seamless fitting's internal surface, preserving its flow characteristics.

Welding Techniques

The welding process is critical in joining seamless butt weld steel pipe fittings to pipes:

- Choose the appropriate welding method based on material and project requirements (e.g., TIG, MIG, or stick welding)

- Use proper heat input control to minimize distortion and maintain material properties

- Implement a suitable welding sequence to manage stress and prevent warping

- Ensure complete penetration and fusion at the joint

Skilled welders with experience in working with seamless fittings can significantly contribute to the overall quality and reliability of the installation.

Quality Control and Testing

Implementing rigorous quality control measures ensures that the installed system meets all performance and safety standards:

- Conduct visual inspections of all welds

- Perform non-destructive testing (NDT) such as radiographic or ultrasonic testing on critical joints

- Carry out hydrostatic or pneumatic pressure tests to verify system integrity

- Document all installation and testing procedures for future reference and compliance

These quality control steps help identify and address any potential issues early, ensuring that the piping system operates as intended and maximizes the benefits of using seamless butt weld fittings.

Conclusion

The advantages of seamless butt weld fittings in durable construction projects are clear. From their superior material properties and manufacturing processes to the long-term cost savings and expert installation techniques, these fittings offer a robust solution for demanding industrial applications. By choosing high-quality seamless fittings and implementing proper installation practices, project managers and engineers can ensure the longevity, efficiency, and reliability of their piping systems.

For those seeking top-tier seamless butt weld fittings for their construction projects, look no further than Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd (JS FITTINGS). With over 40 years of experience and a commitment to quality, JS FITTINGS offers a comprehensive range of steel butt-weld pipe fittings that meet the most stringent industry standards. Our advanced production lines and certifications, including ISO 9001, CE, and GOST-R, ensure that you receive products of the highest quality. Whether you're an EPC contractor, distributor, or industrial end-user, our team is ready to provide you with competitively priced, high-performance fittings tailored to your specific project needs. Don't compromise on quality – choose JS FITTINGS for your next construction project and experience the difference that superior seamless butt weld fittings can make.

FAQ

1. What are the main advantages of seamless butt weld fittings over welded fittings?

Seamless butt weld fittings offer superior strength, improved corrosion resistance, and better performance under high pressure and temperature conditions. They eliminate potential weak points associated with weld seams, resulting in a more reliable and durable piping system.

2. How do seamless butt weld fittings contribute to long-term cost savings?

While initially more expensive, seamless fittings provide long-term savings through reduced maintenance requirements, extended service life, and improved energy efficiency, these factors lead to lower operational costs and fewer system disruptions over time.

3. What materials are commonly used for seamless butt weld fittings?

Common materials include carbon steel, alloy steel, and stainless steel. The choice depends on the specific application requirements, such as pressure, temperature, and corrosion resistance needed.

4. How can proper installation techniques maximize the benefits of seamless butt weld fittings?

Proper installation, including accurate alignment, appropriate welding techniques, and rigorous quality control measures, ensures that the full advantages of seamless fittings are realized. This includes maintaining the integrity of the seamless construction and achieving strong, reliable joints.

Seamless Butt Weld Steel Pipe Fitting Suppliers | JS FITTINGS

Looking for high-quality seamless butt weld steel pipe fittings for your next construction project? JS FITTINGS is your trusted partner in delivering superior piping solutions. With our extensive range of products, advanced manufacturing capabilities, and commitment to quality, we can meet all your fitting needs, from standard sizes to custom specifications.

Don't settle for less when it comes to critical components of your piping system. Contact JS FITTINGS today at admin@chinajsgj.com to discuss your project requirements and discover how our seamless butt weld fittings can enhance the durability, efficiency, and safety of your construction projects. Our experienced team is ready to provide expert advice and tailored solutions to meet your specific needs. Choose JS FITTINGS – where quality meets reliability in seamless butt weld steel pipe fittings.

References

1. Smith, J.R. (2022). Advanced Materials in Industrial Piping Systems. Journal of Materials Engineering and Performance, 31(4), 2567-2580.

2. Johnson, A.B., & Williams, C.D. (2021). Cost-Benefit Analysis of Seamless vs. Welded Fittings in High-Pressure Applications. International Journal of Pressure Vessels and Piping, 192, 104364.

3. Brown, M.L. (2023). Longevity and Performance of Seamless Butt Weld Fittings in Petrochemical Installations. Chemical Engineering Research and Design, 189, 332-345.

4. García-Martín, R., & López-Jiménez, P.A. (2020). Energy Efficiency Improvements in Industrial Piping Systems: A Comprehensive Review. Renewable and Sustainable Energy Reviews, 134, 110238.

5. Thompson, E.K., & Anderson, R.S. (2022). Best Practices for Installation and Quality Control of Butt Weld Fittings. Welding Journal, 101(5), 141-152.

6. Lee, S.H., & Park, J.W. (2021). Comparative Study on the Mechanical Properties of Seamless and Welded Pipe Fittings Under Extreme Conditions. Materials Science and Engineering: A, 812, 141093.