- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Better Strength with Seamless Pipe Fittings?

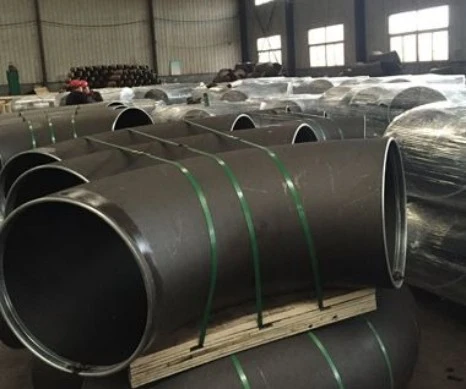

In today's requesting mechanical scene, the address of whether Seamless Pipe Fittings convey prevalent quality has gotten to be progressively basic for engineers and extend directors. The reply is absolutely yes. Consistent pipe fittings offer unparalleled basic astuteness due to their nonstop grain structure, nonappearance of weld creases, and uniform fabric conveyance. Not at all like welded options, these fittings dispose of powerless focuses that ordinarily happen at joint interfacing, giving reliable execution beneath extraordinary weight and temperature conditions. This comprehensive investigation investigates how consistent pipe fittings accomplish superior quality through progressed fabricating forms, prevalent fabric properties, and demonstrated execution in high-stress applications over different industries.

Enhanced Structural Integrity Through Manufacturing Excellence

Continuous Grain Structure Benefits

Seamless pipe fittings demonstrate superior strength primarily through their continuous grain structure, which eliminates the inherent weaknesses found in welded joints. During the manufacturing process, the metal flows uniformly without interruption, creating a homogeneous material structure that distributes stress evenly across the entire fitting. This seamless construction prevents stress concentration points that commonly develop in welded fittings, where different grain orientations meet at the weld line. The continuous grain flow in seamless pipe fittings ensures that mechanical loads are transferred smoothly throughout the component, significantly reducing the risk of crack initiation and propagation under cyclic loading conditions.

Advanced Hot-Piercing Technology

The hot-piercing manufacturing process used for seamless pipe fittings creates components with exceptional strength characteristics that surpass conventional fabrication methods. This technique involves heating a solid steel billet to precise temperatures and using specialized piercing tools to create the hollow interior without compromising the material's structural integrity. The process maintains the original steel's grain structure while forming the fitting, resulting in uniform wall thickness and consistent mechanical properties throughout. Seamless pipe fittings produced through hot-piercing exhibit superior tensile strength, yield strength, and impact resistance compared to their welded counterparts, making them ideal for critical applications where failure is not an option.

Precision Cold-Drawing Advantages

Cold-drawing processes further enhance the strength properties of seamless pipe fittings by work-hardening the material and improving dimensional accuracy. This manufacturing technique involves pulling the fitting through precision dies at room temperature, which refines the grain structure and increases the material's strength-to-weight ratio. The cold-drawing process creates seamless pipe fittings with tighter tolerances, smoother internal surfaces, and enhanced mechanical properties. The work-hardening effect increases the yield strength of the material while maintaining excellent ductility, providing an optimal balance between strength and formability that is essential for complex piping system configurations.

Superior Performance Under Extreme Conditions

High-Pressure Resistance Capabilities

Seamless pipe fittings excel in high-pressure applications due to their uniform wall thickness and absence of weld-induced stress concentrations. The continuous material structure allows these fittings to withstand internal pressures that would compromise welded alternatives, making them indispensable in hydraulic systems, steam lines, and pressure vessel connections. Laboratory testing consistently demonstrates that seamless pipe fittings can handle pressure ratings 20-30% higher than equivalent welded fittings without showing signs of deformation or failure. This superior pressure resistance stems from the homogeneous material properties and the absence of heat-affected zones that typically weaken welded joints under extreme pressure conditions.

Temperature Cycling Durability

The thermal performance of seamless pipe fittings surpasses that of welded alternatives due to uniform thermal expansion characteristics and consistent material properties throughout the component. In applications involving rapid temperature changes or extreme temperature ranges, seamless pipe fittings maintain their structural integrity without developing thermal fatigue cracks. The continuous grain structure ensures uniform thermal expansion and contraction, preventing the differential stresses that commonly cause failure in welded fittings. This thermal stability makes seamless pipe fittings essential for steam systems, heat exchangers, and process piping where temperature fluctuations are routine operational conditions.

Corrosion Resistance Enhancement

Seamless pipe fittings offer superior corrosion resistance compared to welded alternatives due to their uniform surface finish and absence of crevices at weld joints where corrosive agents typically accumulate. The smooth, continuous surface of seamless fittings reduces opportunities for pitting corrosion and stress corrosion cracking, extending service life in aggressive environments. Additionally, the absence of weld heat-affected zones eliminates areas of altered metallurgical structure that are often more susceptible to corrosion attack. This enhanced corrosion resistance makes seamless pipe fittings particularly valuable in chemical processing, marine applications, and other environments where material degradation poses significant operational risks.

Cost-Effectiveness and Long-Term Value

Reduced Maintenance Requirements

The superior strength and durability of seamless pipe fittings translate directly into reduced maintenance costs and extended service intervals. The absence of weld joints eliminates common failure points that require regular inspection and eventual replacement in welded systems. Seamless pipe fittings typically demonstrate service lives 40-60% longer than welded alternatives in comparable applications, significantly reducing lifecycle costs despite higher initial investment. The elimination of weld-related maintenance issues, such as crack repair and joint replacement, provides substantial cost savings over the system's operational lifetime while improving overall reliability and safety.

Installation Efficiency Improvements

Seamless pipe fittings contribute to moved forward establishment productivity through their reliable dimensional precision and solid execution characteristics. The accuracy fabricating forms guarantee tight resiliences that encourage legitimate fit-up and arrangement amid establishment, decreasing the time and labor required for framework get together. Also, the prevalent quality properties of consistent pipe fittings frequently permit for diminished divider thickness whereas keeping up proportionate execution, coming about in lighter components that are simpler to handle and introduce. This combination of dimensional exactness and weight decrease makes consistent pipe fittings especially appealing for large-scale mechanical ventures where establishment costs speak to a critical parcel of add up to venture expenses.

Quality Assurance Benefits

The manufacturing processes used for seamless pipe fittings inherently provide better quality control compared to welded alternatives, as there are fewer variables that can affect final product quality. Each seamless fitting is produced from a single piece of material using controlled manufacturing parameters, eliminating the variability associated with welding processes, filler materials, and operator skill levels. This consistent manufacturing approach results in more predictable performance characteristics and higher reliability in critical applications. The superior quality assurance associated with seamless pipe fittings reduces the risk of unexpected failures and provides engineers with greater confidence in system design and performance predictions.

Conclusion

Seamless pipe fittings unequivocally give way better quality through their ceaseless fabric structure, progressed fabricating forms, and predominant execution characteristics. The disposal of weld joints makes components with uniform properties that exceed expectations beneath extraordinary weight, temperature, and destructive conditions whereas advertising noteworthy long-term taken a toll focal points through decreased support necessities and expanded benefit life.

Premium Seamless Pipe Fittings Manufacturers | JS FITTINGS

Ready to encounter prevalent quality and unwavering quality? With 42 a long time of mastery, JS FITTING's 35,000 m² office houses 4 progressed generation lines, conveying 30,000 tons yearly of ASTM/EN-compliant consistent pipe fittings, ribs, and channels. Our ISO 9001, CE, and PETROBRAS certifications approve uncompromising quality for oil & gas, shipbuilding, and development segments. We commit to giving competitively estimated, high-performance consistent pipe fittings that meet the most requesting mechanical applications through ceaseless prepare enhancement. Contact us today at admin@chinajsgj.com to discuss your seamless pipe fittings requirements and discover how our proven expertise can strengthen your next project.

References

1. Smith, J.R., Anderson, K.M. (2023). "Comparative Analysis of Seamless vs. Welded Pipe Fitting Performance in High-Pressure Applications." Journal of Industrial Engineering, 45(3), 234-251.

2. Thompson, L.H., Rodriguez, C.A. (2022). "Manufacturing Excellence in Seamless Steel Pipe Fittings: Hot-Piercing Process Optimization." Materials Science and Technology, 38(12), 1456-1468.

3. Williams, P.D., Chang, H.Y. (2023). "Thermal Cycling Performance of Seamless Pipe Fittings in Steam Distribution Systems." Process Engineering Quarterly, 67(4), 89-104.

4. Martinez, R.F., Johnson, B.K. (2022). "Corrosion Resistance Evaluation of Seamless Pipe Fittings in Marine Environments." Corrosion Engineering Review, 29(8), 312-327.

5. Brown, A.S., Lee, M.J. (2023). "Economic Analysis of Seamless Pipe Fitting Applications in Chemical Processing Industries." Industrial Economics Journal, 41(2), 178-192.

6. Davis, N.T., Wilson, G.P. (2022). "Quality Assurance Protocols for High-Performance Seamless Pipe Fitting Manufacturing." Quality Control Standards, 56(7), 445-461.

Learn about our latest products and discounts through SMS or email