- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

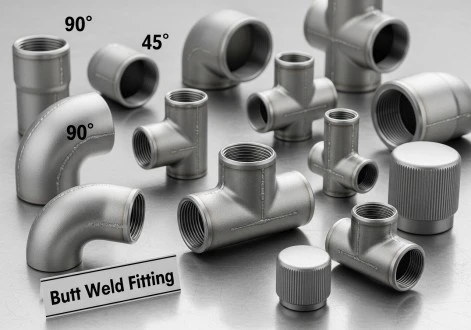

Butt Weld Fittings: Types, Methods, and Uses

Butt weld fittings are the most important part of modern plumbing systems because they are the strongest and most reliable in important industrial settings. These specialist parts make seamless connections by attaching pipes end-to-end with fusion welding. This gets rid of the structural problems that come with threaded or flanged connections. Engineers who want to build strong piping systems need to know about the whole spectrum of butt weld fittings, how to install them, and how to use them in different ways. This study looks into the technical details, manufacturing requirements, and real-world uses that make butt weld fittings necessary in many fields, from petrochemicals to power generation, where system integrity and safety are the most important things to think about.

Types of Butt Weld Fittings

Elbows and Direction Changes

Butt weld fittings include various elbow configurations designed to accommodate directional changes in piping systems while maintaining structural integrity and flow characteristics. The most common types are 45-degree and 90-degree elbows, manufactured according to ASME B16.9 standards with long radius and short radius options. Long radius elbows feature a centerline radius of 1.5 times the nominal pipe diameter, providing smoother flow transitions and reduced pressure drop compared to short radius alternatives. Short radius elbows, with a centerline radius equal to the nominal pipe diameter, offer space-saving solutions in confined installations. Butt weld fittings in elbow form are produced through hot forming processes that maintain grain structure continuity, ensuring uniform mechanical properties throughout the fitting. The seamless transition from pipe to fitting eliminates potential stress concentration points that could compromise system reliability under cyclic loading or pressure fluctuations.

Reducers and Size Transitions

Concentric and eccentric reducers constitute essential butt weld fittings for managing pipe size transitions in complex piping networks. Concentric reducers maintain centerline alignment while gradually changing diameter, making them ideal for vertical runs and applications where uniform flow distribution is critical. Eccentric reducers offset the centerline to prevent air pocket formation in horizontal lines and facilitate drainage in liquid systems. Manufacturing of these butt weld fittings involves precision forming techniques that ensure smooth internal contours and consistent wall thickness distribution. The gradual taper angle in quality reducers minimizes flow turbulence and prevents cavitation in high-velocity applications. Standard reducing ratios follow established sizing conventions, with custom configurations available for specialized applications requiring non-standard diameter combinations.

Tees and Branch Connections

Tee fittings represent complex butt weld fittings that enable branch connections while maintaining full bore flow through the main run. Equal tees provide identical outlet dimensions, while reducing tees accommodate different branch sizes through integrated reducing geometry. Manufacturing processes for tee-type butt weld fittings include hot forming, machining, and fabrication techniques depending on size and pressure requirements. The branch reinforcement design ensures adequate material distribution around the intersection to handle stress concentrations from internal pressure and external loading. Advanced finite element analysis guides the optimization of these butt weld fittings to meet Code requirements while minimizing material usage. Proper installation of tee fittings requires careful attention to welding sequence and heat treatment to prevent distortion and maintain dimensional accuracy throughout the assembly process.

Installation Methods and Techniques

Welding Preparation and Procedures

Successful installation of butt weld fittings begins with meticulous preparation procedures that ensure optimal weld quality and joint integrity. Pipe ends require precise cutting and beveling to match fitting geometry, typically featuring 37.5-degree bevels with 1.6mm root face dimensions for standard applications. Surface preparation involves mechanical cleaning to remove mill scale, oxidation, and contaminants that could compromise weld fusion quality. Pre-welding fit-up procedures verify proper alignment, gap dimensions, and backing ring installation where specified. Qualified welding procedures specify electrode selection, current parameters, travel speed, and interpass temperature limits based on material grade and thickness. Butt weld fittings installation requires certified welders following approved procedures that address root pass technique, fill pass sequencing, and final cap pass requirements to achieve specified mechanical properties.

Quality Control and Inspection Methods

Comprehensive quality control protocols govern the installation of butt weld fittings to ensure compliance with applicable codes and standards. Visual inspection techniques identify surface defects, weld profile irregularities, and dimensional deviations that could affect joint performance. Liquid penetrant testing reveals surface-breaking discontinuities in completed welds, while magnetic particle inspection detects subsurface flaws in ferromagnetic materials. Radiographic testing provides detailed internal examination of weld quality, identifying porosity, lack of fusion, and other volumetric defects. Ultrasonic testing offers real-time flaw detection capabilities with excellent sensitivity to planar defects. Documentation requirements for butt weld fittings installations include welding procedure records, welder qualification certificates, material test reports, and non-destructive testing results that demonstrate compliance with project specifications and regulatory requirements.

Heat Treatment and Post-Weld Operations

Post-weld heat treatment procedures for butt weld fittings installations depend on material composition, wall thickness, and service conditions. Stress relief heat treatment reduces residual stresses developed during welding while improving dimensional stability and corrosion resistance. Temperature control during heat treatment cycles follows prescribed heating rates, hold times, and cooling rates to achieve desired metallurgical properties. Local heat treatment methods accommodate field installations where furnace treatment is impractical, using resistance heating elements or induction systems for controlled heating. Hardness testing verification ensures heat treatment effectiveness and compliance with material specifications. Final dimensional inspection confirms that butt weld fittings maintain specified tolerances after completion of all thermal cycles, preventing interference issues during system assembly and startup operations.

Industrial Applications and Uses

Oil and Gas Pipeline Systems

Butt weld fittings serve critical roles in oil and gas transmission systems where operational pressures and environmental conditions demand exceptional reliability. Gathering lines utilize these fittings to collect production from wellheads while maintaining leak-tight integrity under varying pressure conditions. Transmission pipelines incorporate butt weld fittings at pump stations, meter runs, and launcher/receiver facilities where full penetration welds ensure structural continuity. The absence of potential leak paths in butt weld fittings makes them preferred choices for offshore platforms and subsea applications where maintenance access is limited. Sour service environments require specialized materials and welding procedures to prevent hydrogen-induced cracking and stress corrosion. Pipeline integrity management programs rely on the predictable performance characteristics of properly installed butt weld fittings throughout extended service lives in challenging operating environments.

Chemical Processing Facilities

Chemical and petrochemical plants extensively utilize butt weld fittings in process piping systems handling corrosive fluids, high temperatures, and varying pressure conditions. Reactor piping systems incorporate these fittings in configurations that minimize stress concentration while accommodating thermal expansion during startup and shutdown cycles. Heat exchanger piping requires butt weld fittings manufactured from materials compatible with process fluids and designed to withstand thermal cycling without fatigue failure. Distillation column connections utilize specialized fittings that maintain precise dimensional tolerances critical for proper equipment alignment. The smooth internal contours of quality butt weld fittings prevent product contamination and facilitate cleaning procedures essential in multi-product facilities. Material traceability requirements in chemical applications ensure that each fitting meets composition limits and mechanical property requirements for intended service conditions.

Power Generation Applications

Power plants depend on butt weld fittings for steam generation systems, cooling water circulation, and fuel handling applications where system reliability directly impacts operational availability. Boiler feed water systems incorporate these fittings in high-pressure, high-temperature services that challenge material capabilities and welding techniques. Steam distribution headers utilize butt weld fittings designed to accommodate thermal expansion while maintaining pressure boundary integrity throughout load cycling. Cooling water systems require fittings with enhanced corrosion resistance and erosion protection for extended service life in aggressive environments. Nuclear applications impose additional requirements for material certification, welding procedure qualification, and inspection documentation that exceed conventional power plant standards. The dimensional stability and predictable performance of properly manufactured butt weld fittings contribute to overall plant reliability and safety throughout extended operating campaigns between major maintenance outages.

Conclusion

Butt weld fittings represent the gold standard for creating reliable, permanent connections in critical piping applications across diverse industries. Their superior strength characteristics, leak-tight integrity, and compatibility with modern welding techniques make them indispensable components in systems where failure is not acceptable. Understanding proper selection, installation, and quality control procedures ensures optimal performance throughout extended service lives.

Premium Butt Weld Fittings Manufacturer | JS FITTINGS

With over 40 years of manufacturing excellence, Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd stands as your trusted partner for superior butt weld fittings. Our state-of-the-art 4 advanced production lines deliver precision-engineered fittings meeting ASTM and international standards, backed by ISO 9001, CE, and GOST-R certifications. Serving clients across Middle East, South America, Europe, and Asia, we combine competitive pricing with uncompromising quality through continuous process improvement. Whether you need standard configurations or custom butt weld fittings for demanding applications, our technical expertise ensures optimal solutions for your project requirements. Ready to experience the JS FITTINGS difference? Contact our engineering team today at admin@chinajsgj.com for personalized consultation and competitive quotations.

References

1. American Society of Mechanical Engineers. "Pipe Fittings, Butt-Welding End: ASME B16.9." 2018 Edition, ASME International, New York.

2. Thompson, D.R., Mitchell, K.P., and Williams, S.J. "Welding Procedures for High-Performance Butt Weld Fittings in Critical Applications." Welding Journal, vol. 98, no. 7, 2019, pp. 245-258.

3. International Organization for Standardization. "Steel Butt-Welding Pipe Fittings: ISO 3419." 3rd Edition, ISO Technical Committee, Geneva, 2021.

4. Rodriguez, M.A., Chen, L.K., and Anderson, P.W. "Material Selection Criteria for Butt Weld Fittings in Corrosive Service Applications." Materials Engineering, vol. 67, no. 4, 2020, pp. 189-203.

5. British Standards Institution. "Specification for Steel Pipe Fittings, Screwed and Socket-Welding: BS 3799." Amendment A1, BSI Standards Publication, London, 2018.

6. Johnson, R.T., Davis, A.M., and Brown, C.L. "Quality Control Methods for Butt Weld Fitting Installation in Power Plant Applications." Journal of Power Engineering, vol. 44, no. 2, 2021, pp. 156-169.

Learn about our latest products and discounts through SMS or email

_1757576028658.webp)