Joint Design and Welding Method Comparison: Butt Weld vs Socket Weld

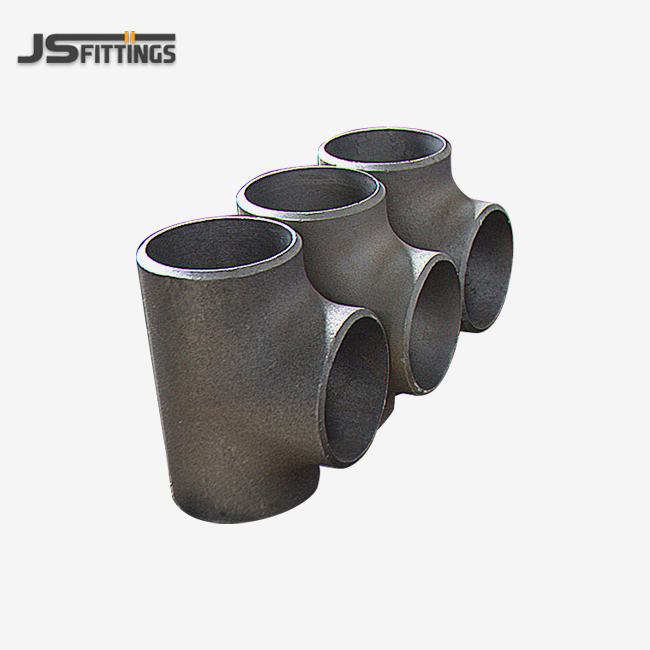

How the joints are made and soldered is what makes socket-weld caps and buttweld end caps different. Full penetration welds are what Buttweld End Cap fits are made for. This makes the connection with the pipe smooth and free of friction. The cap and pipe parts can bond together fully in this design, making a strong joint that can handle high temperatures and pressures.

Buttweld End Cap Characteristics:

- Full penetration weld

- Seamless connection

- Higher strength joint

- Suitable for high-pressure applications

- Requires precise edge preparation

On the other hand, socket-weld caps have a hole that goes over the pipe end. The joint is put on the outside, where the cap meets the outside of the pipe. As a rule, this method is simple to use. However, the joint may not be as strong as a butt weld.

Socket-Weld Cap Characteristics:

- External weld

- Easier installation

- Lower strength compared to butt welds

- Suitable for smaller diameter pipes

- Potential for crevice corrosion

The choice between these welding methods often depends on factors such as pipe size, system pressure, and accessibility for welding equipment. Buttweld End Cap fittings are typically preferred for critical applications where maximum joint strength and integrity are paramount.

Size and Pressure Suitability: When to Use Each Style?

The selection between Buttweld End Cap fittings and socket-weld caps is heavily influenced by the size of the piping system and the operating pressure requirements. Understanding these factors is crucial for ensuring optimal performance and safety in your industrial applications.

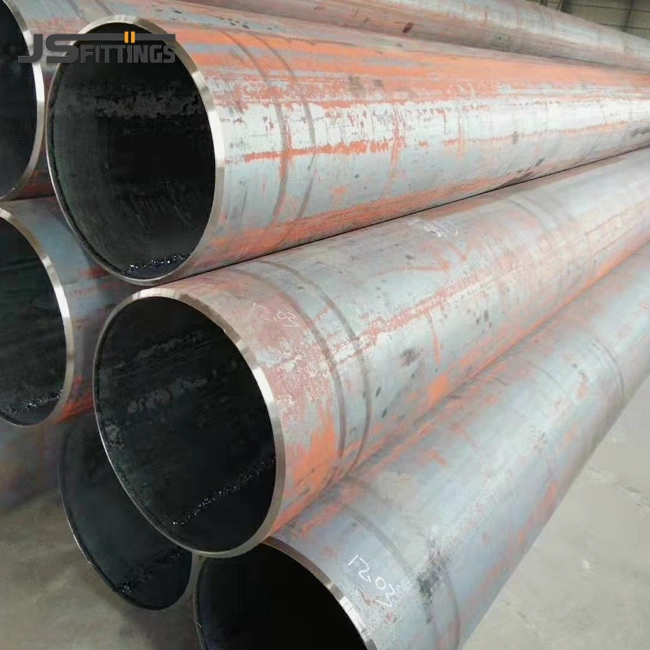

Buttweld End Caps: Ideal for Larger Diameters and High Pressures

Buttweld end caps are the preferred choice for larger diameter pipes and high-pressure systems. Their design allows for a stronger, more reliable seal that can withstand extreme conditions. Typically, buttweld caps are used in the following scenarios:

- Pipe sizes 2 inches and above

- High-pressure systems exceeding 3000 psi

- Critical process lines where joint integrity is paramount

- Applications requiring full material traceability

Socket-Weld Caps: Suitable for Smaller Diameters and Moderate Pressures

Socket-weld caps are more commonly used in smaller diameter piping systems and moderate pressure applications. They offer advantages in terms of ease of installation and are often chosen for:

- Pipe sizes up to 2 inches

- Moderate pressure systems up to 3000 psi

- Applications where frequent disassembly may be required

- Systems with space constraints for welding equipment

It's important to note that these guidelines for Buttweld End Cap fittings can vary depending on specific industry standards and project requirements. Always consult relevant codes and specifications when making your selection.

Inspection, Maintenance Frequency, and Crevice Corrosion Risk

The choice between Buttweld End Cap fittings and socket-weld caps not only affects initial installation but also has long-term implications for inspection, maintenance, and corrosion resistance. Understanding these factors is crucial for ensuring the longevity and reliability of your piping system.

Inspection and Maintenance Considerations

Buttweld end caps generally require less frequent inspections due to their robust joint design. The full penetration weld creates a seamless connection that is less prone to failure or leakage. Key points include:

- Lower inspection frequency for buttweld joints

- Easier visual inspection of weld quality

- Reduced risk of hidden defects

Socket-weld caps, while easier to install, may require more frequent inspections due to the potential for crevice formation. Inspection considerations for socket-weld caps include:

- Higher inspection frequency, especially in corrosive environments

- Need for specialized inspection techniques to assess internal joint quality

- Potential for hidden corrosion in the socket area

Crevice Corrosion Risk

One of the significant advantages of buttweld end caps is their reduced risk of crevice corrosion. The smooth, gap-free joint eliminates potential sites for corrosion to initiate. In contrast, socket-weld caps have an inherent risk of crevice corrosion due to the small gap between the pipe and the socket.

Factors influencing crevice corrosion risk:

- Choice of material (for example, types of stainless steel)

- Setting for work (temperature, chemicals, etc.)

- Quality of weld execution

- Presence of stagnant fluids in the system

To mitigate crevice corrosion risk in socket-weld applications, careful material selection, proper welding procedures, and regular inspections are essential. In highly corrosive environments or critical applications, buttweld end cap fittings are often the preferred choice due to their superior resistance to crevice corrosion.

Conclusion

In conclusion, you can use both Buttweld End Cap fits and socket-weld caps. Pick one based on the pipe's size, the pressure that needs to be used, the fitting's limits, and how often it will need to be serviced. This is because weld end caps last longer, are stronger, and rust less often. This makes them better for long lines and tough cases. Socket-weld caps are simple to put on and work well with lines that don't have to do as much work in places with smaller sizes.

FAQ

1. What are the main advantages of Buttweld End Cap fittings?

Buttweld End Cap fittings offer superior joint strength, higher pressure ratings, and reduced risk of crevice corrosion. They are ideal for larger diameter pipes and critical applications requiring maximum integrity.

2. When should socket-weld caps be used instead of buttweld caps?

Socket-weld caps are typically used for smaller diameter pipes (up to 2 inches), in moderate pressure systems, and where ease of installation is a priority. They're also suitable for applications that may require frequent disassembly.

3. How does the welding process differ between buttweld and socket-weld caps?

Buttweld caps require full penetration welds, creating a seamless connection with the pipe. Socket-weld caps are welded externally, joining the cap to the pipe's outer surface. Buttweld joints generally require more skill and precision to execute properly.

4. What factors should be considered when choosing between buttweld and socket-weld caps?

Key factors include pipe size, system pressure, operating temperature, corrosion risk, inspection requirements, and installation constraints. The specific industry standards and project specifications should also be taken into account.

Quality Buttweld End Cap Fittings Manufacturer | JS FITTINGS

Want to buy high-quality butt weld end cap fittings for a business project? The buttweld fittings that JS FITTINGS sells are all made to the best standards. Our products have been approved by ISO 9001, CE, and GOST-R, so you can be sure that they will always get the job done well. Because we have high-tech production lines and a lot of knowledge, we can make anything you want in any size or material. We can help you with your job by giving you low prices and getting it to you on time, whether you need normal fits or new ones. Contact us today at admin@chinajsgj.com to discuss your Buttweld End Cap fitting needs and experience the JS FITTINGS difference in quality and service.

References

1. American Society of Mechanical Engineers. (2021). ASME B16.9: Factory-Made Wrought Buttwelding Fittings.

2. European Committee for Standardization. (2019). EN 10253: Butt-welding pipe fittings.

3. Nayyar, M. L. (2000). Piping Handbook (7th ed.). McGraw-Hill Education.

4. American Welding Society. (2020). AWS D10.4: Recommended Practices for Welding Austenitic Chromium-Nickel Stainless Steel Piping and Tubing.

5. Antaki, G. A. (2003). Piping and Pipeline Engineering: Design, Construction, Maintenance, Integrity, and Repair. CRC Press.

6. Lam, P. S., & Brust, F. W. (2018). Welding and Joining of Advanced High-Strength Steels (AHSS). Woodhead Publishing.