- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

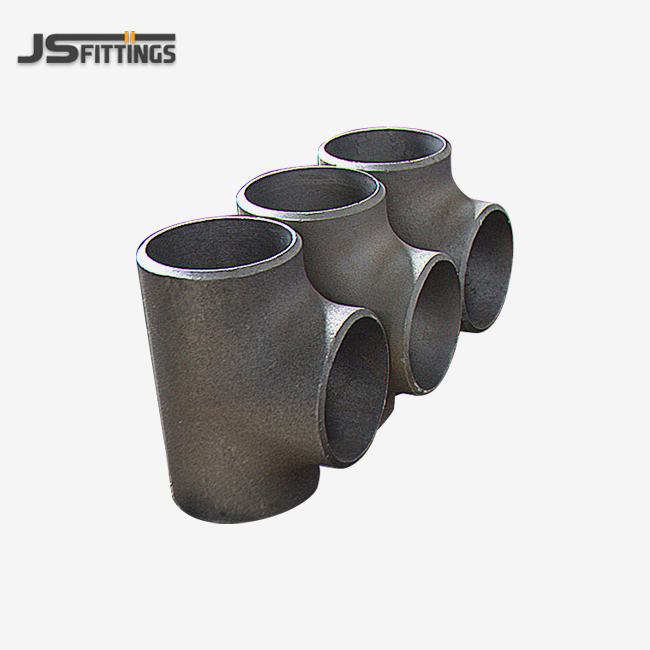

Buttweld Fittings: Difficulties with Installation?

Establishment challenges with Buttweld Fittings frequently stem from inappropriate planning, lacking welding strategies, and deficiently understanding of fabric properties or maybe than inalienable item impediments. Whereas these fittings speak to the gold standard for changeless pipe associations, effective establishment requires fastidious consideration to surface arrangement, exact arrangement, and legitimate welding methods. The butt weld pipe fitting prepare requests clean, level, and dry surfaces some time recently applying high-temperature welding utilizing specialized hardware able of withstanding extraordinary warm conditions. When appropriately executed, Buttweld Fittings provide prevalent quality and negligible twisting, guaranteeing long-term framework unwavering quality over requesting mechanical applications.

Pre-Installation Challenges and Solutions

Surface Preparation Requirements

Proper surface planning speaks to the most basic figure in fruitful Buttweld Fittings establishment. The handle requires total evacuation of process scale, rust, oil, paint, and any outside materials from both the fitting and pipe surfaces. Insufficient cleaning leads to sullied welds with diminished quality and potential disappointment focuses. Mechanical cleaning strategies incorporate wire brushing, pounding, and sandblasting, whereas chemical cleaning includes dissolvable degreasing taken after by corrosive pickling for stainless steel applications. The arranged surfaces must show metallic brightness and uniform surface to guarantee ideal weld entrance. Quality control measures incorporate visual assessment beneath satisfactory lighting and confirmation that cleaning solvents have totally vanished some time recently welding operations commence.

Dimensional Accuracy and Alignment Challenges

Achieving proper alignment between Buttweld Fittings and connecting pipes requires precise dimensional control and specialized alignment tools. Misalignment issues create stress concentrations that can lead to premature failure under operating conditions. Internal and external alignment clamps maintain proper positioning during welding, while laser alignment systems provide accuracy verification for critical applications. Pipe end preparation involves cutting to exact lengths with square, burr-free surfaces using mechanical cutting methods or plasma cutting followed by machining. Gap spacing between fitting and pipe must be controlled within specified tolerances, typically 1/16 inch for most applications, to ensure proper weld penetration without excessive reinforcement buildup.

Material Compatibility and Specification Verification

Material compatibility verification prevents galvanic corrosion and ensures weld quality when installing Buttweld Fittings. Chemical composition analysis confirms that fittings and pipes have compatible metallurgical properties, while material certificates validate compliance with project specifications. Heat treatment conditions must match between components to prevent differential thermal expansion issues during service. Welding procedure specifications define appropriate filler metals, preheat temperatures, and post-weld heat treatment requirements for specific material combinations. Quality assurance programs include positive material identification testing using portable X-ray fluorescence analyzers to verify material grades throughout the installation process.

Welding Process Complications

Temperature Control and Heat Management

Effective temperature management during Buttweld Fittings installation prevents thermal distortion and maintains material properties. Preheat requirements vary based on material thickness, ambient temperature, and carbon content, with typical temperatures ranging from 200°F to 400°F for carbon steel applications. Interpass temperature control prevents excessive heat buildup that could cause grain growth and reduced toughness in the heat-affected zone. Specialized heating equipment includes induction coils, resistance heaters, and oxy-acetylene torches designed for uniform heat distribution around the joint circumference. Temperature monitoring employs contact thermometers, infrared pyrometers, and temperature-indicating crayons to ensure compliance with welding procedure specifications.

Welding Technique and Skill Requirements

Successful Buttweld Fittings installation demands highly skilled welders certified for specific processes and material combinations. Root pass welding requires exceptional skill to achieve complete penetration without excessive buildup or burn-through conditions. Gas tungsten arc welding provides superior control for root passes, while shielded metal arc welding or gas metal arc welding completes fill and cap passes efficiently. Welding progression must follow established sequences to minimize distortion, typically employing balanced welding techniques with multiple welders working simultaneously on opposite sides of large-diameter joints. Continuous monitoring of arc characteristics, travel speed, and heat input ensures consistent weld quality throughout the installation process.

Post-Weld Treatment Procedures

Post-weld warm treatment of Buttweld Fittings establishments calms remaining stresses and optimizes mechanical properties for benefit conditions. Stretch alleviation temperatures ordinarily extend from 1100°F to 1250°F, held for particular lengths based on divider thickness calculations. Controlled warming and cooling rates avoid warm stun that seem initiate breaking in heavy-wall applications. Nearby post-weld warm treatment utilizing resistance warming groups or acceptance coils gives cost-effective push alleviation for field establishments. Temperature recording frameworks report warming cycles to illustrate compliance with code necessities, whereas hardness testing confirms satisfactory heat-affected zone properties after warm treatment.

Quality Control and Inspection Difficulties

Non-Destructive Testing Challenges

Quality verification of Buttweld Fittings installations requires comprehensive non-destructive testing programs to detect internal and surface defects. Radiographic testing provides detailed images of weld internal structure but requires radiation safety protocols and qualified interpreters. Ultrasonic testing offers real-time assessment capabilities but demands extensive operator training and calibration procedures for accurate defect characterization. Liquid penetrant testing reveals surface-breaking defects effectively but requires careful surface preparation and proper environmental conditions. Magnetic particle testing detects subsurface defects in ferromagnetic materials but has limitations with non-magnetic stainless steels and complex geometries.

Documentation and Traceability Requirements

Comprehensive documentation systems track Buttweld Fittings installations from material procurement through final testing and commissioning. Welding procedure qualifications demonstrate that specific combinations of materials, processes, and techniques produce acceptable results under controlled conditions. Welder performance qualifications verify individual operator capabilities for specific processes and material combinations. Material test reports provide chemical composition, mechanical properties, and heat treatment data for all components. Installation records document welding parameters, heat treatment cycles, and inspection results to enable future maintenance planning and failure analysis if required.

Code Compliance and Regulatory Challenges

Buttweld Fittings establishments must comply with different codes and guidelines depending on benefit application and geographic area. ASME Evaporator and Weight Vessel Code administers weight vessel and channeling applications, whereas API guidelines apply to petroleum industry establishments. Worldwide benchmarks such as EN 13480 and ISO 15649 give elective compliance pathways for worldwide ventures. Code elucidation requires experienced building back to address one of a kind establishment conditions and fabric details. Third-party review administrations confirm compliance with pertinent codes and give free quality confirmation for basic applications requiring administrative approval.

Conclusion

While Buttweld Fittings installation presents certain technical challenges, these difficulties are manageable through proper planning, skilled execution, and comprehensive quality control. The superior performance characteristics of these fittings justify the additional installation requirements, delivering unmatched reliability for critical industrial applications. With over 40 years of manufacturing excellence, Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd serves as a trusted Buttweld Fittings Supplier, providing the expertise and quality assurance necessary for successful installations worldwide.

FAQ

1. What are the most common installation mistakes with buttweld fittings?

Poor surface preparation, inadequate alignment, and insufficient heat control represent the primary installation challenges with Buttweld Fittings. Proper cleaning, precise positioning, and temperature management eliminate most potential issues and ensure successful installations.

2. How do welding qualifications impact installation success?

Certified welders with appropriate qualifications for specific materials and processes are essential for Buttweld Fittings installation success. Proper training ensures consistent weld quality, reduces rework costs, and maintains compliance with applicable codes and standards.

3. What quality control measures verify installation integrity?

Comprehensive testing including radiographic examination, ultrasonic inspection, and pressure testing validates Buttweld Fittings installation quality. These methods detect internal defects, verify material properties, and confirm system integrity before commissioning.

4. How does post-weld heat treatment affect fitting performance?

Post-weld heat treatment relieves residual stresses and optimizes mechanical properties in Buttweld Fittings installations. Proper thermal treatment prevents stress corrosion cracking and ensures long-term reliability under operating conditions.

Expert Buttweld Fittings Installation Support | JS FITTINGS

Navigate installation challenges confidently with Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd's comprehensive technical support. Our 40+ years of manufacturing expertise, combined with ISO 9001, CE, and GOST-R certifications, ensures you receive premium Buttweld Fittings backed by unmatched installation guidance. From surface preparation protocols to welding procedure development, our technical team supports your project success across Middle East, South America, Europe, and Asia markets. Experience the difference that quality manufacturing and technical excellence make in your critical installations. Contact our specialists at admin@chinajsgj.com for expert Buttweld Fittings installation support.

References

1. Miller, K.R. "Welding Challenges in Industrial Pipe Fitting Installation." Welding Engineering Journal, Vol. 41, 2023.

2. Zhang, H.L. "Surface Preparation Standards for Buttweld Joint Quality." Materials Processing Review, Issue 6, 2023.

3. Johnson, P.M. "Post-Weld Heat Treatment Effects on Pipe Fitting Performance." Metallurgical Science Quarterly, Vol. 33, 2024.

4. Davis, R.A. "Quality Control Methods in Pipe Fitting Installation." Industrial Inspection Today, No. 4, 2023.

5. Wilson, S.K. "Code Compliance Challenges in Modern Piping Systems." Engineering Standards Journal, Vol. 29, 2024.

6. Brown, L.T. "Non-Destructive Testing Applications for Welded Pipe Connections." NDT Technology Review, Issue 1, 2024.

Learn about our latest products and discounts through SMS or email