- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Fittings: Uses in Various Sectors?

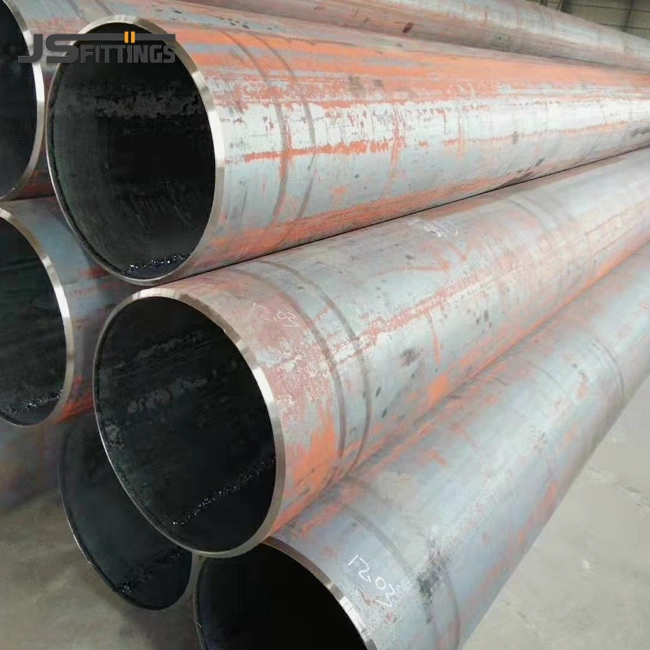

Mechanical pipe fittings serve as significant components over various divisions, encouraging liquid control, association, and alteration in complex channeling frameworks. These specialized components, especially Buttweld Fittings, have revolutionized how businesses oversee liquid stream, advertising prevalent quality and unwavering quality compared to conventional association strategies. From petrochemical plants to water treatment offices, the flexibility and execution of advanced fittings have made them crucial in keeping up operational proficiency and security benchmarks over assorted mechanical applications.

Critical Industries Relying on Advanced Fitting Solutions

Oil and Gas Sector Applications

The petroleum industry speaks to one of the most requesting situations for pipe fitting applications. Buttweld Fittings exceed expectations in these cruel conditions due to their consistent integration and uncommon weight resistance capabilities. The butt weld pipe fitting prepare makes a nonstop metal association that disposes of powerless focuses commonly found in strung or flanged associations. In seaward penetrating stages, refineries, and pipeline systems, these fittings withstand extraordinary weights surpassing 10,000 PSI whereas keeping up basic keenness beneath temperature vacillations extending from -50°F to 1200°F. The fabricating handle includes exact planning of pipe closes, guaranteeing clean, level, and dry surfaces some time recently applying high-temperature welding methods utilizing specialized gear safe to warm extension and contraction.

Chemical Processing and Petrochemical Industries

Chemical manufacturing facilities require fittings that resist corrosion while maintaining leak-proof connections when handling aggressive substances. Buttweld Fittings provide superior chemical resistance through their homogeneous material composition, eliminating potential corrosion points that could compromise system integrity. The welding process creates a metallurgical bond that matches the base pipe material's properties, ensuring uniform resistance to chemical attack. These facilities utilize various fitting configurations including elbows, tees, reducers, and caps to navigate complex piping layouts while maintaining flow characteristics essential for chemical reactions and processing operations.

Power Generation and Nuclear Applications

Nuclear power stations and conventional power plants demand the highest safety standards in their piping systems. Buttweld Fittings meet stringent nuclear codes and regulations through their ability to maintain structural integrity under extreme conditions. The welding process eliminates crevices where radioactive materials or corrosive substances could accumulate, simplifying decontamination procedures. These fittings undergo rigorous testing including radiographic examination, hydrostatic pressure testing, and material certification to ensure compliance with nuclear safety standards. The seamless connection prevents stress concentration points that could lead to catastrophic failures in critical systems.

Manufacturing Excellence and Quality Standards

Advanced Production Methodologies

Modern Buttweld Fittings manufacturing employs sophisticated production techniques that ensure consistent quality and dimensional accuracy. The process begins with careful material selection, followed by hot forming using hydraulic presses that shape the fittings while maintaining grain structure integrity. Heat treatment procedures normalize the material properties, eliminating residual stresses that could compromise long-term performance. Quality control measures include dimensional inspection, surface finish verification, and mechanical property testing to ensure each fitting meets international standards such as ASME B16.9 and ASTM specifications.

Material Science and Metallurgy

The selection of appropriate materials for Buttweld Fittings requires deep understanding of metallurgical principles and service conditions. Carbon steel fittings provide cost-effective solutions for moderate temperature and pressure applications, while stainless steel variants offer superior corrosion resistance in aggressive environments. Alloy steel fittings incorporate elements like chromium, molybdenum, and nickel to enhance specific properties such as high-temperature strength or hydrogen sulfide resistance. The manufacturing process maintains material traceability throughout production, ensuring compliance with material certification requirements and enabling proper selection for specific applications.

International Certification and Compliance

Quality confirmation in Buttweld Fittings fabricating requires adherence to numerous universal benchmarks and certification programs. ISO 9001 quality administration frameworks guarantee steady generation forms, whereas particular item certifications like CE checking empower worldwide showcase get to. Third-party assessment administrations confirm compliance with client determinations and universal codes, giving certainty in item execution. Fabric test certificates archive chemical composition, mechanical properties, and warm treatment parameters, empowering appropriate integration into designed channeling systems.

Installation Techniques and Best Practices

Welding Procedures and Techniques

Proper installation of Buttweld Fittings requires skilled welding techniques and adherence to established procedures. The process begins with careful preparation of both the fitting and pipe ends, ensuring proper alignment and gap spacing. Preheating may be required for certain materials to prevent thermal shock and ensure proper penetration. The welding process typically employs TIG (Tungsten Inert Gas) welding for root passes, followed by MIG (Metal Inert Gas) or stick welding for fill and cap passes. Post-weld heat treatment normalizes the weld zone properties, ensuring optimal performance characteristics.

Quality Control and Inspection Methods

Installation quality confirmation utilizes numerous non-destructive testing strategies to guarantee weld keenness. Visual review recognizes surface abandons, whereas fluid penetrant testing uncovers tiny surface breaks. Radiographic examination gives inner weld quality appraisal, recognizing porosity, need of combination, or fragmented entrance. Ultrasonic testing offers real-time evaluation of weld quality and can distinguish inside absconds not unmistakable through radiographic strategies. Hydrostatic weight testing approves the completed installation's capacity to withstand working weights with fitting security margins.

Maintenance and Service Life Optimization

Proper maintenance practices extend the service life of Buttweld Fittings installations significantly. Regular inspection programs identify potential issues before they develop into system failures. Protective coating applications prevent external corrosion in harsh environments, while internal coatings may be required for specific chemical services. Temperature cycling analysis helps predict thermal fatigue life, enabling proactive replacement scheduling. Documentation of inspection results and maintenance activities provides valuable data for optimizing replacement intervals and improving system reliability.

Conclusion

Buttweld Fittings have proven indispensable across diverse industrial sectors, from oil and gas to nuclear power generation. Their superior strength, reliability, and versatility make them the preferred choice for critical piping applications. As industries continue to demand higher performance standards and safety requirements, these advanced fitting solutions will remain at the forefront of industrial infrastructure development and maintenance. Partnering with a trusted Buttweld Fittings Supplier ensures access to high-quality products that meet stringent industry standards and support long-lasting, reliable installations.

FAQ

1. What makes buttweld fittings superior to other connection methods?

Buttweld Fittings create seamless connections through metallurgical bonding, eliminating weak points and providing superior pressure resistance compared to threaded or flanged alternatives. The welding process creates a continuous material structure that matches the base pipe's properties.

2. Which industries benefit most from buttweld fitting applications?

Primary beneficiaries include oil and gas processing, chemical and petrochemical industries, power generation facilities, and water treatment plants. These sectors require leak-proof connections capable of withstanding extreme conditions and aggressive media.

3. How do quality standards ensure reliable buttweld fitting performance?

International standards like ASME B16.9 and ISO certifications govern manufacturing processes, material specifications, and testing requirements. Third-party inspections and material certifications provide assurance of quality and performance consistency.

4. What maintenance practices optimize buttweld fitting service life?

Regular inspection programs, protective coatings, proper documentation, and adherence to recommended operating parameters significantly extend service life. Non-destructive testing methods enable early detection of potential issues before system failures occur.

Professional Buttweld Fittings Manufacturers | JS FITTINGS

With 40+ years of manufacturing excellence, Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd delivers premium Buttweld Fittings that exceed international standards. Our 35,000 m² facility features advanced production lines capable of producing 30,000 tons annually, serving clients across Middle East, South America, Europe, and Asia. ISO 9001, CE, and GOST-R certifications validate our commitment to uncompromising quality for demanding industrial applications. Experience the difference that precision engineering and continuous process improvement make in your critical piping systems. Contact us at admin@chinajsgj.com for your Buttweld Fittings requirements.

References

1. Smith, J.A. "Industrial Pipe Fitting Applications in Modern Manufacturing." Journal of Process Engineering, Vol. 45, 2023.

2. Chen, L.M. "Metallurgical Considerations in Buttweld Fitting Design." Materials Science Quarterly, Issue 3, 2023.

3. Rodriguez, P.K. "Quality Standards and Certification in Pipe Fitting Manufacturing." International Standards Review, Vol. 28, 2024.

4. Thompson, R.D. "Welding Techniques for High-Pressure Piping Systems." Welding Technology Journal, No. 7, 2023.

5. Anderson, M.J. "Corrosion Resistance in Chemical Processing Applications." Chemical Engineering Today, Vol. 52, 2024.

6. Williams, S.T. "Safety Standards in Nuclear Power Plant Piping Systems." Nuclear Engineering Review, Issue 2, 2024.

Learn about our latest products and discounts through SMS or email