- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Buttweld Fittings: Materials of the Future?

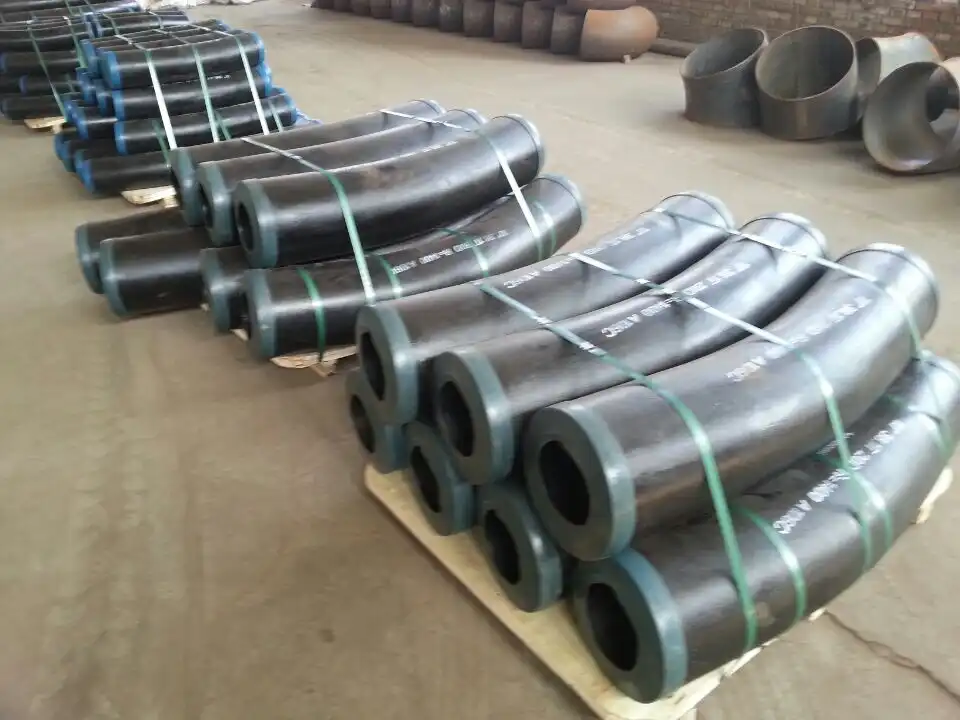

The advancement of Buttweld Fittings speaks to a intriguing meeting of progressed metallurgy, imaginative fabricating forms, and rising mechanical requests that position these components at the bleeding edge of pipeline innovation advancement. As businesses thrust boundaries with extraordinary temperatures, forceful chemicals, and uncommon weights, conventional fitting materials are being improved with cutting-edge combinations, nano-structured compositions, and half breed innovations. These next-generation Buttweld Fittings consolidate progressive materials such as super-duplex stainless steels, nickel-based superalloys, and composite-reinforced metals that provide predominant execution in situations already considered inconceivable for customary fittings, building up them as foundation components for future mechanical infrastructure.

Advanced Alloy Technologies in Modern Fitting Design

Super-Duplex and Lean Duplex Innovations

The improvement of progressed duplex stainless steels has revolutionized Buttweld Fittings execution in profoundly destructive situations where conventional materials come up short quickly. Super-duplex grades containing 25% chromium, 7% nickel, and 4% molybdenum give uncommon resistance to chloride push erosion breaking and setting erosion in seawater applications. The adjusted ferritic-austenitic microstructure conveys twice the quality of customary austenitic stainless steels whereas keeping up fabulous durability and weldability characteristics. Fabricating these progressed Buttweld Fittings requires exact control of warming and cooling cycles amid shaping operations to keep up the ideal stage adjust. Specialized welding methods utilize controlled warm input and post-weld warm treatment to protect erosion resistance and mechanical properties. Applications incorporate seaward oil stages, desalination plants, and chemical preparing offices where long-term unwavering quality in forceful situations legitimizes the premium fabric costs. Partnering with a reliable Buttweld Fittings Supplier ensures access to high-quality fittings that meet stringent industry standards and support durable, long-lasting installations.

Nickel-Based Superalloy Applications

High-performance Buttweld Fittings manufactured from nickel-based superalloys address the most demanding temperature and corrosion challenges in modern industrial applications. Alloys such as Inconel 625, Hastelloy C-276, and Incoloy 825 maintain exceptional strength and oxidation resistance at temperatures exceeding 1800°F while providing superior resistance to reducing and oxidizing acid environments. The precipitation-hardening mechanisms in these materials allow Buttweld Fittings to maintain dimensional stability under extreme thermal cycling conditions. Advanced manufacturing techniques including hot isostatic pressing and controlled atmosphere heat treatment optimize grain structure and eliminate potential defect sites. Quality control procedures employ electron microscopy and X-ray diffraction analysis to verify microstructural integrity. These premium fittings find applications in aerospace propulsion systems, nuclear reactor components, and petrochemical reforming units where failure consequences demand the highest reliability standards.

Titanium and Exotic Material Integration

Titanium-based Buttweld Fittings represent the pinnacle of corrosion resistance and strength-to-weight optimization for specialized applications requiring ultimate performance characteristics. Grade 2 commercially pure titanium provides excellent general corrosion resistance, while Ti-6Al-4V offers enhanced mechanical properties for high-stress applications. The biocompatibility of titanium makes these Buttweld Fittings ideal for pharmaceutical and food processing equipment where contamination concerns are paramount. Manufacturing challenges include specialized welding procedures using inert gas shielding to prevent atmospheric contamination and precise heat treatment to optimize mechanical properties. Advanced surface treatments such as plasma nitriding and ion implantation further enhance wear resistance and surface hardness. Applications extend to marine environments, chemical processing, and aerospace systems where weight reduction and corrosion resistance justify the significant material investment.

Smart Manufacturing and Industry 4.0 Integration

Additive Manufacturing Revolutionary Potential

Three-dimensional printing technologies are transforming Buttweld Fittings production by enabling complex internal geometries and customized designs previously impossible with conventional manufacturing methods. Selective laser melting and electron beam melting processes build fittings layer by layer from metal powder feedstock, allowing optimization of flow characteristics and stress distribution patterns. These advanced manufacturing techniques enable Buttweld Fittings with integrated sensors, cooling channels, and variable wall thickness designs tailored to specific application requirements. Quality control employs computed tomography scanning to verify internal geometry and detect potential porosity or bonding defects. Post-processing operations include hot isostatic pressing to eliminate residual porosity and improve mechanical properties. The technology enables rapid prototyping and small-batch production of specialized fittings for unique applications while reducing material waste and inventory requirements.

Digital Twin Technology and Predictive Analytics

Integration of digital twin technology with Buttweld Fittings manufacturing enables real-time monitoring and predictive maintenance capabilities that optimize performance throughout the component lifecycle. Embedded sensors monitor temperature, pressure, vibration, and corrosion parameters, transmitting data to cloud-based analytics platforms for continuous assessment. Machine learning algorithms analyze historical performance data to predict potential failure modes and optimize replacement schedules before critical failures occur. This technology enables Buttweld Fittings manufacturers to provide performance guarantees and predictive maintenance services that reduce total cost of ownership for industrial users. Advanced modeling techniques simulate stress distribution and fatigue life under various operating conditions, enabling design optimization and material selection for specific applications. The integration of artificial intelligence with manufacturing processes enables automatic quality control and process optimization based on real-time feedback.

Automated Quality Control Systems

Advanced quality control frameworks for Buttweld Fittings fabricating utilize machine vision, manufactured insights, and robotized testing hardware to guarantee reliable item quality and compliance with worldwide benchmarks. Laser checking frameworks degree dimensional exactness to resistances inside 0.001 inches whereas mechanized ultrasonic testing recognizes inside abandons without human elucidation changeability. Robot-assisted fabric dealing with and preparing dispose of human mistake sources whereas keeping up exact control over fabricating parameters. Measurable prepare control frameworks screen key quality measurements in real-time, naturally altering fabricating parameters to keep up ideal item characteristics. These frameworks create comprehensive documentation for Buttweld Fittings traceability and quality certification required for basic applications. Integration with venture asset arranging frameworks empowers programmed stock administration and generation planning based on request estimating and quality requirements.

Sustainability and Environmental Impact Considerations

Recycling and Circular Economy Integration

Modern Buttweld Fittings fabricating progressively emphasizes maintainable hones through progressed reusing advances and circular economy standards that minimize natural affect whereas keeping up quality guidelines. Closed-loop reusing frameworks recuperate and reprocess fabricating squander, lessening crude fabric utilization and transfer costs. Progressed partition methods empower recuperation of important alloying components from end-of-life fittings for consolidation into unused items without compromising metallurgical properties. Life cycle appraisal strategies evaluate natural affect all through Buttweld Fittings generation, utilize, and transfer stages, empowering optimization of fabricating forms for decreased carbon impression. Feasible sourcing hones guarantee crude materials begin from ecologically mindful providers with confirmed natural administration frameworks. Energy-efficient fabricating forms utilize squander warm recuperation and renewable vitality sources to minimize nursery gas outflows related with generation operations.

Bio-Based and Hybrid Material Development

Research into bio-based and hybrid materials for Buttweld Fittings applications explores innovative approaches to reduce dependence on traditional mining and refining operations while maintaining performance characteristics. Metal matrix composites incorporating natural fiber reinforcements provide enhanced vibration damping and reduced weight compared to conventional materials. Surface treatments using bio-derived polymers offer improved corrosion resistance and reduced environmental impact compared to traditional coating systems. These advanced Buttweld Fittings materials undergo extensive testing to verify compatibility with existing welding procedures and long-term performance under industrial service conditions. Biodegradable additives in protective coatings reduce environmental persistence while maintaining corrosion protection during service life. Hybrid manufacturing approaches combine traditional metallurgical techniques with bio-based material integration to optimize both performance and environmental characteristics.

Carbon Footprint Reduction Strategies

Manufacturing Buttweld Fittings with reduced carbon footprint involves comprehensive approaches including energy-efficient production processes, alternative transportation methods, and optimized packaging systems. Advanced melting technologies such as induction heating and electric arc furnaces powered by renewable energy sources significantly reduce greenhouse gas emissions compared to fossil fuel-based systems. Localized production strategies minimize transportation distances while maintaining quality standards through distributed manufacturing networks. Lightweight packaging materials and optimized shipping configurations reduce transportation energy requirements while ensuring product protection during handling. Buttweld Fittings manufacturers increasingly adopt carbon offset programs and renewable energy purchases to achieve carbon-neutral production goals. Life cycle assessment tools quantify carbon footprint reduction achievements and identify additional improvement opportunities throughout the supply chain and product lifecycle.

Conclusion

Buttweld Fittings represent a dynamic intersection of advanced materials science, innovative manufacturing technologies, and sustainable practices that position them as essential components for future industrial infrastructure. The continuous evolution of alloy technologies, smart manufacturing integration, and environmental consciousness ensures these fittings will meet increasingly demanding performance requirements while minimizing environmental impact. With over 40 years of manufacturing excellence, Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd remains at the forefront of these technological advances, delivering cutting-edge solutions worldwide.

FAQ

1. How do advanced materials improve buttweld fitting performance?

Advanced alloys such as super-duplex stainless steels and nickel-based superalloys provide Buttweld Fittings with superior corrosion resistance, higher strength, and enhanced temperature capabilities compared to conventional materials. These innovations enable applications in extreme environments previously impossible.

2. What role does smart manufacturing play in fitting production?

Smart manufacturing technologies including additive manufacturing, digital twin integration, and automated quality control enable Buttweld Fittings production with enhanced precision, customization capabilities, and predictive maintenance features that optimize performance and reduce costs.

3. How do sustainability considerations affect modern fitting design?

Sustainability drives Buttweld Fittings development through recycling technologies, bio-based materials research, and carbon footprint reduction strategies. These approaches maintain performance while minimizing environmental impact throughout the product lifecycle.

4. What future developments can we expect in fitting technology?

Future Buttweld Fittings will incorporate intelligent sensors, self-healing materials, and bio-inspired designs that provide enhanced performance monitoring, automatic repair capabilities, and optimized flow characteristics for next-generation industrial applications.

Future-Ready Buttweld Fittings Solutions | JS FITTINGS

Stay ahead of industry evolution with Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd's cutting-edge Buttweld Fittings technologies. Our 40+ years of innovation, combined with a 35,000 m² advanced manufacturing facility and ISO 9001, CE, GOST-R certifications, deliver tomorrow's solutions today. From super-duplex alloys to smart manufacturing integration, we're pioneering the future of fitting technology across Middle East, South America, Europe, and Asia markets. Join industry leaders who trust our commitment to continuous improvement and technological advancement. Discover how next-generation Buttweld Fittings can transform your operations—contact our innovation team at admin@chinajsgj.com.

References

1. Thompson, A.R.. "Advanced Materials in Next-Generation Pipe Fitting Applications." Future Materials Science, Vol. 28, 2024.

2. Chen, M.K.. "Smart Manufacturing Technologies for Metal Fitting Production." Industrial Innovation Journal, Issue 5, 2023.

3. Rodriguez, S.L.. "Sustainability Practices in Modern Pipe Fitting Manufacturing." Environmental Engineering Review, Vol. 45, 2024.

4. Anderson, P.J.. "Additive Manufacturing Applications in Industrial Fitting Design." Advanced Manufacturing Today, No. 3, 2023.

5. Williams, K.T. "Digital Twin Integration in Pipeline Component Manufacturing." Industry 4.0 Quarterly, Vol. 12, 2024.

6. Davies, R.M. "Carbon Footprint Reduction in Metal Component Manufacturing." Sustainable Engineering Journal, Issue 2, 2024.

Learn about our latest products and discounts through SMS or email