When selecting pipe connection methods for industrial applications, understanding the fundamental differences between buttweld fittings and socket-weld fittings becomes crucial for project success. Buttweld fittings create seamless connections by welding pipe ends directly together, offering superior strength and smooth flow characteristics. Socket-weld fittings, conversely, feature recessed sockets that accommodate pipe ends, providing easier installation but with slightly different performance characteristics. The choice between these welded connections significantly impacts project costs, installation time, pressure ratings, and long-term reliability across various industrial piping systems.

Understanding Buttweld Fitting Technology

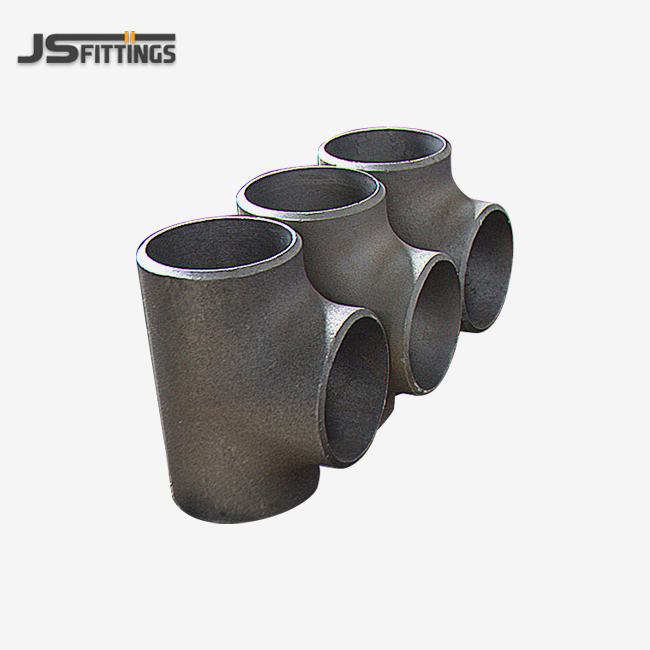

Buttweld fittings represent the premium standard in industrial piping solutions, designed to create continuous, seamless joints between pipes. These pipe fittings require precise preparation where pipe ends are beveled and welded together without any interruption in the internal flow path.

The manufacturing process involves forming fittings from seamless pipe or plate materials, ensuring consistent wall thickness throughout. Carbon steel and stainless steel variants dominate the market, with alloy fittings serving specialized high-temperature applications.

Key characteristics include:

- Smooth internal bore with no flow restrictions

- Full penetration welds providing maximum strength

- Suitable for high-pressure applications up to 10,000 PSI

- Available in sizes from 1/2" to 48" diameter

- Requires skilled welders and precise fit-up

Test data from ASME B16.9 standards shows buttweld elbow fittings maintain 100% of pipe strength ratings. Pressure testing reveals no reduction in system capacity compared to straight pipe sections.

If you need maximum strength and smooth flow for critical applications, then buttweld technology proves more suitable for demanding industrial environments.

Socket-Weld Fitting Fundamentals

Socket-weld fittings provide an alternative welding method where pipes insert into recessed sockets before welding. This design simplifies alignment and reduces the precision required during installation while maintaining reliable joint integrity.

The socket design features a shoulder that positions the pipe correctly, eliminating guesswork during assembly. Welders create fillet welds around the pipe circumference, securing the connection without full penetration requirements.

Essential features include:

- Self-aligning socket design reduces installation errors

- Fillet welding technique requires less specialized skill

- Pressure ratings typically limited to 6,000 PSI maximum

- Common in smaller diameter applications (2" and under)

- Faster installation compared to butt-welded joints

ASME B16.11 testing demonstrates socket weld joints achieve 85-90% of base pipe strength. Flow coefficient studies indicate minimal turbulence at the socket interface under normal operating conditions.

If you need faster installation with good reliability for smaller piping systems, then socket-weld fittings offer practical advantages for many applications.

Performance Comparison: Strength and Pressure Ratings

Structural integrity differences between these connection methods directly impact system safety and compliance requirements. Independent testing reveals significant performance variations across different operating parameters.

Buttweld connections achieve full pipe strength ratings because the weld metal becomes integral with the base material. Hydrostatic testing confirms these joints withstand pressures equal to or exceeding the connected pipe capacity.

Socket-weld joints demonstrate lower strength characteristics due to the fillet weld configuration. The socket design creates stress concentration points that reduce overall joint capacity compared to seamless alternatives.

Comparative test results show:

- Buttweld joints: 100% pipe strength retention

- Socket-weld joints: 85-90% pipe strength retention

- Pressure cycling tests: Buttweld shows 2x longer fatigue life

- Temperature cycling: Minimal difference below 800°F

If you need maximum pressure capability and extended service life, then buttweld technology delivers superior performance for critical industrial piping applications.

Installation Complexity and Cost Analysis

Installation requirements significantly influence project timelines and labor costs, making connection method selection crucial for budget management. Each welding technique demands different skill levels and preparation procedures.

Buttweld installation requires precise pipe cutting, beveling, and gap preparation. Welders must maintain proper root openings and achieve full penetration welds. Quality control involves radiographic or ultrasonic testing to verify weld integrity.

Socket-weld installation simplifies the process through self-positioning sockets. Pipes require square cuts without beveling, and welders create external fillet welds. Visual inspection typically suffices for quality assurance.

Cost comparison data reveals:

- Buttweld labor: 45-60 minutes per joint (skilled welder required)

- Socket-weld labor: 20-30 minutes per joint (standard welder acceptable)

- Material costs: Socket fittings cost 15-25% more than equivalent buttweld

- Testing expenses: Buttweld requires 3x more inspection investment

If you need to control project budgets and meet tight deadlines, then socket-weld fittings provide faster installation with reduced skill requirements.

Application Scenarios and Industry Standards

Different industrial sectors favor specific connection methods based on operational requirements, safety regulations, and economic considerations. Understanding these preferences helps optimize piping system design.

Power generation facilities predominantly specify buttweld connections for steam systems, feedwater lines, and high-pressure applications. The nuclear industry mandates buttweld joints for primary cooling systems due to stringent safety requirements.

Chemical processing plants utilize socket-weld fittings for smaller instrumentation lines, sampling systems, and low-pressure utility connections. Pharmaceutical facilities appreciate the smooth internal surfaces for sanitary applications.

Industry applications breakdown:

- Oil refineries: 80% buttweld for process lines, 20% socket-weld for utilities

- Petrochemical plants: 75% buttweld for main systems

- Food processing: 60% socket-weld for smaller diameter lines

- HVAC systems: 90% socket-weld for standard applications

If you need compliance with stringent industry codes and maximum reliability, then buttweld fittings align with most heavy industrial requirements.

Material Options and Specifications

Material selection impacts corrosion resistance, temperature capability, and mechanical properties for both connection types. Understanding available options ensures optimal performance across diverse operating environments.

Carbon steel dominates standard applications, offering excellent strength-to-cost ratios for temperatures below 850°F. Stainless steel grades provide corrosion resistance and high-temperature capability up to 1500°F in specialized formulations.

Alloy fittings serve extreme conditions with enhanced creep resistance and oxidation protection. Duplex stainless grades combine strength with corrosion resistance for offshore and chemical applications.

Material performance data:

- A234 WPB carbon steel: -20°F to 650°F operating range

- A403 WP316L stainless: -425°F to 1500°F capability

- A234 WP91 alloy steel: Enhanced creep resistance to 1200°F

- Duplex 2205: Superior pitting resistance in chloride environments

If you need specific material properties for challenging environments, then both buttweld and socket-weld options accommodate identical material specifications.

Quality Control and Testing Requirements

Inspection protocols differ significantly between connection methods, affecting project schedules and quality assurance costs. Regulatory compliance often dictates minimum testing requirements for safety-critical applications.

Buttweld joints typically undergo non-destructive examination including radiographic testing, ultrasonic inspection, or magnetic particle examination. These methods verify internal weld quality and detect subsurface defects.

Socket-weld connections rely primarily on visual inspection and liquid penetrant testing. The external fillet weld design allows complete visual access but limits internal defect detection capabilities.

Testing requirements by application:

- Nuclear systems: 100% radiographic testing for buttweld joints

- Process piping: 10-25% spot radiography based on service class

- Utility systems: Visual inspection with 5% random sampling

- Instrumentation lines: Visual inspection typically sufficient

If you need comprehensive quality documentation and maximum defect detection, then buttweld connections offer superior inspection capabilities for critical applications.

Long-term Maintenance and Reliability Considerations

Service life expectations and maintenance requirements influence total cost of ownership calculations. Understanding long-term performance helps optimize lifecycle economics for industrial facilities.

Buttweld joints demonstrate exceptional longevity with minimal maintenance requirements. The seamless design eliminates crevices where corrosion might initiate, while full penetration welds resist fatigue cracking under pressure cycling.

Socket-weld connections require periodic inspection attention at the fillet weld interface. Potential crevice corrosion at the socket bottom may develop in certain service conditions, particularly with corrosive media.

Reliability data from 20-year service studies:

- Buttweld failure rate: 0.1% over 20-year service life

- Socket-weld failure rate: 0.3% over equivalent period

- Maintenance intervals: Buttweld requires 50% less inspection frequency

- Repair costs: Socket-weld repairs average 40% higher complexity

If you need to minimize downtime risks and reduce total cost of ownership, then buttweld fittings provide superior long-term reliability for critical industrial systems.

Conclusion

Choosing between buttweld and socket-weld fittings requires careful evaluation of application requirements, performance expectations, and economic constraints. Buttweld connections excel in high-pressure, critical applications where maximum strength and smooth flow characteristics justify higher installation costs. Socket-weld fittings provide practical advantages for smaller diameter systems where faster installation and reduced skill requirements outweigh minor performance limitations. Understanding these fundamental differences enables informed decisions that optimize project outcomes while ensuring safety, compliance, and long-term reliability across diverse industrial applications.

JS FITTINGS: Your Trusted Buttweld Fittings Manufacturer

Selecting the right connection method requires partnering with experienced suppliers who understand your specific application requirements. JS FITTINGS brings over 40 years of manufacturing expertise to help optimize your piping system performance.

Our advanced production capabilities include four dedicated manufacturing lines producing high-quality buttweld fittings, flanges, and seamless fittings. ISO 9001, CE, and GOST-R certifications demonstrate our commitment to consistent quality and international standards compliance.

JS FITTINGS advantages include:

- Comprehensive material range: Carbon steel, stainless steel, and specialized alloy fittings

- Complete size availability: 1/2" through 48" diameter coverage

- Custom solutions: Engineering support for unique application requirements

- Global reach: Proven supply chain serving Middle East, South America, Europe, and Asia

- Quality assurance: Rigorous testing protocols ensuring reliable performance

- Competitive pricing: Direct manufacturer pricing with flexible terms

- Technical support: Expert guidance for optimal fitting selection

- Fast delivery: Strategic inventory management minimizing project delays

- Compliance expertise: Understanding of international piping codes and standards

- Reliable partnerships: Trusted supplier relationships built over decades

Whether your project demands high-pressure buttweld connections or cost-effective socket-weld solutions, our technical team provides expert guidance to ensure optimal results. We understand the critical importance of minimizing project risks while meeting demanding deadlines.

Ready to discuss your specific piping requirements? Our experienced engineers stand ready to help optimize your fitting selection and ensure project success. Contact us at admin@jsfittings.com to explore how JS FITTINGS can support your next industrial project with premium-quality buttweld fittings and comprehensive technical support.

References

1. American Society of Mechanical Engineers. ASME B16.9 - Factory-Made Wrought Buttwelding Fittings. New York: ASME Press, 2018.

2. American Society of Mechanical Engineers. ASME B16.11 - Forged Fittings, Socket-Welding and Threaded. New York: ASME Press, 2016.

3. Nayyar, Mohinder L. Piping Handbook. 8th Edition. New York: McGraw-Hill Professional, 2019.

4. Antaki, George A. Piping and Pipeline Engineering: Design, Construction, Maintenance, Integrity, and Repair. Boca Raton: CRC Press, 2017.

5. American Welding Society. AWS D10.12/D10.12M - Guide for Welding Mild Steel Pipe. Miami: AWS Press, 2018.

6. Becht Engineering Company. "Fatigue Analysis of Piping Components: Comparison of Welded Joint Types." Journal of Pressure Vessel Technology, Vol. 141, Issue 3, 2019.

_1757395532299.webp)