Selecting the right buttweld elbow involves understanding material specifications, pressure ratings, dimensional standards, and application requirements. The best buttweld elbow combines optimal flow characteristics, corrosion resistance, and compatibility with your pipeline system. Key factors include radius type (long or short), angle configuration (90-degree or 45-degree), material grade (carbon steel or stainless steel), and compliance with ANSI or ASME specifications. Quality manufacturing ensures seamless integration, reduces maintenance costs, and enhances system reliability across diverse industrial applications.

Why Buttweld Elbows Matter in Industrial Piping Systems?

Industrial piping systems form the backbone of countless operations across manufacturing facilities, oil refineries, chemical plants, and infrastructure projects. The selection of appropriate pipe fittings directly impacts system performance, operational safety, and long-term maintenance costs. Buttweld elbows represent critical components that facilitate smooth flow direction changes while maintaining structural integrity under varying pressure conditions.

Poor fitting selection leads to premature failures, costly downtime, and potential safety hazards. Conversely, well-chosen buttweld elbows enhance flow efficiency, reduce turbulence, and provide decades of reliable service. Understanding the nuances of elbow selection becomes essential for project managers, procurement specialists, and engineering teams responsible for pipeline system design and implementation.

Essential Selection Criteria for Optimal Performance

Evaluating buttweld elbows requires systematic consideration of multiple technical and operational factors. Material compatibility stands as the primary concern, ensuring chemical resistance and temperature tolerance match application demands. Pressure rating verification prevents catastrophic failures while dimensional accuracy guarantees proper fit within existing pipeline configurations.

Manufacturing quality indicators include seamless construction, consistent wall thickness, and adherence to international standards. Supplier reliability encompasses delivery timelines, technical support availability, and quality assurance protocols. Cost-effectiveness balances initial investment against lifecycle performance, considering factors such as corrosion resistance, maintenance requirements, and expected service life.

Certification compliance ensures regulatory adherence across different markets and applications. Documentation completeness facilitates project approval processes and quality audits. These criteria collectively determine the suitability of specific elbow configurations for demanding industrial environments.

Top 5 Buttweld Elbow Configurations for Industrial Applications

90-Degree Long Radius Carbon Steel Elbow

This configuration represents the most widely specified elbow type across industrial piping applications. The long radius design provides a centerline radius equal to 1.5 times the nominal pipe diameter, resulting in minimal pressure drop and reduced flow turbulence. Carbon steel construction offers excellent strength characteristics and cost-effectiveness for moderate temperature and pressure applications.

Key advantages include:

- Optimal flow characteristics reducing energy consumption

- Cost-effective material selection for budget-conscious projects

- Wide availability in standard dimensions from 1/2" to 48"

- Excellent weldability ensuring reliable joint integrity

- Proven performance in water, steam, and hydrocarbon applications

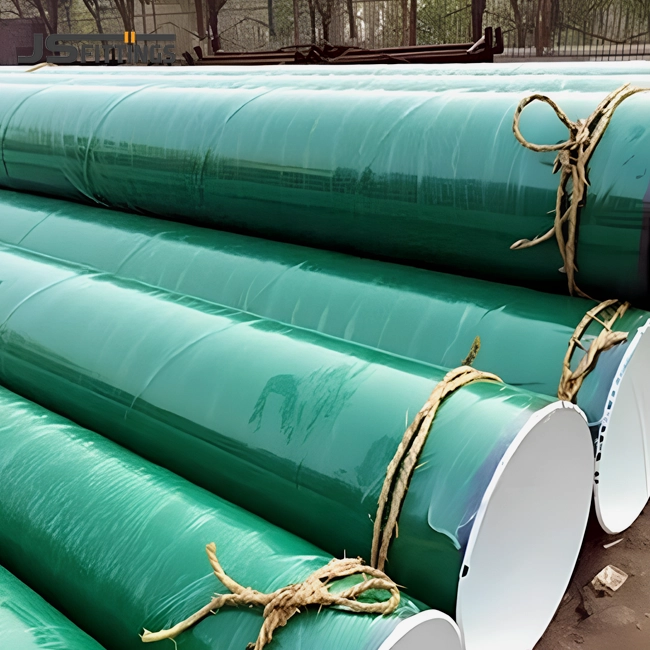

Manufacturing typically follows ASTM A234 WPB specifications, ensuring consistent material properties and dimensional accuracy. The seamless construction eliminates potential weak points associated with welded seams. Surface preparation allows for various protective coatings extending service life in corrosive environments.

Applications span municipal water systems, industrial process piping, HVAC installations, and general plumbing applications. The 90-degree configuration accommodates most directional changes required in pipeline layouts while maintaining structural efficiency.

45-Degree Stainless Steel Elbow

Stainless steel 45-degree elbows provide superior corrosion resistance combined with moderate flow direction changes. The reduced angle minimizes pressure losses compared to 90-degree configurations while offering excellent chemical compatibility across diverse process fluids. Grade 304 and 316 variants address different corrosion resistance requirements.

Key advantages include:

- Exceptional corrosion resistance extending service life

- Reduced pressure drop compared to 90-degree alternatives

- Hygienic surface finish suitable for food and pharmaceutical applications

- Temperature resistance accommodating extreme operating conditions

- Low maintenance requirements reducing operational costs

The 45-degree angle proves particularly valuable in space-constrained installations where gradual direction changes prevent excessive stress concentrations. Stainless steel composition resists pitting, crevice corrosion, and stress corrosion cracking common in aggressive chemical environments.

Manufacturing standards typically reference ASTM A403 specifications ensuring material traceability and performance consistency. The seamless construction maintains uniform wall thickness throughout the elbow geometry, eliminating potential failure points.

Short Radius 90-Degree Elbow

Short radius Buttweld Elbows feature a centerline radius equal to the nominal pipe diameter, creating compact installations where space limitations restrict standard long radius configurations. While generating higher pressure losses, these fittings provide essential functionality in confined areas and specialized applications.

Key advantages include:

- Compact design accommodating space-constrained installations

- Reduced material costs for specific application requirements

- Standard availability across common pipe sizes

- Simplified inventory management for maintenance operations

- Suitable for low-velocity applications where pressure drop remains acceptable

Applications include equipment connections, manifold assemblies, and retrofit projects where existing infrastructure limits available space. The increased turbulence and pressure drop require careful consideration during system design to ensure adequate flow capacity.

Material options encompass carbon steel, stainless steel, and alloy variants depending on service conditions. Manufacturing quality remains critical given the tighter bend radius potentially creating stress concentrations during fabrication.

Large Diameter Seamless Elbow

Large diameter seamless elbows serve critical infrastructure projects including power generation, petrochemical processing, and municipal utilities. Sizes ranging from 24" to 48" accommodate high-volume flow requirements while maintaining structural integrity under significant internal pressures.

Key advantages include:

- Seamless construction eliminating longitudinal weld seams

- Superior strength characteristics for high-pressure applications

- Consistent wall thickness throughout the elbow geometry

- Reduced inspection requirements compared to welded alternatives

- Enhanced reliability for critical infrastructure applications

Manufacturing involves advanced forming techniques creating smooth internal surfaces optimizing flow characteristics. Quality control procedures include ultrasonic testing, dimensional verification, and material certification ensuring compliance with project specifications.

The seamless construction proves particularly valuable in applications involving cyclic loading, thermal expansion, and high-pressure conditions where weld integrity might compromise long-term performance.

High-Alloy Specialty Elbow

Specialty alloy elbows address extreme service conditions involving high temperatures, aggressive chemicals, or specialized process requirements. Materials include Inconel, Hastelloy, duplex stainless steel, and other engineered alloys providing superior performance in demanding applications.

Key advantages include:

- Exceptional chemical resistance in aggressive environments

- High-temperature performance exceeding standard material capabilities

- Specialized compositions addressing specific process requirements

- Extended service life reducing replacement frequency

- Compliance with stringent industry specifications

Applications encompass chemical processing, offshore oil platforms, nuclear facilities, and aerospace ground support equipment. The specialized nature requires careful material selection based on detailed process analysis and compatibility studies.

Manufacturing involves precise composition control, specialized heat treatment, and extensive testing protocols ensuring performance consistency. Documentation includes material certificates, test reports, and traceability records supporting quality assurance requirements.

Regional Market Characteristics and Considerations

Understanding regional preferences, regulations, and market dynamics enhances procurement success across diverse geographic markets. Each region presents unique challenges and opportunities requiring tailored approaches to supplier selection and product specification.

Latin American markets emphasize cost-effectiveness while maintaining acceptable quality standards. Local content requirements often influence procurement decisions, favoring suppliers with regional manufacturing capabilities or partnerships. Spanish and Portuguese language support facilitates communication and technical documentation requirements.

Canadian markets prioritize compliance with CSA standards and cold-weather performance characteristics. Environmental regulations influence material selection and manufacturing processes. The proximity to major industrial centers requires reliable supply chains supporting just-in-time delivery requirements. Buttweld elbows are essential in Canadian markets for their ability to provide reliable, leak-free connections in both high-pressure and low-temperature conditions.

African markets focus on durability and low maintenance requirements given infrastructure limitations and service accessibility challenges. Value engineering approaches balance performance requirements with budget constraints. Local capacity building initiatives favor suppliers offering training and technical support.

Southeast Asian markets emphasize rapid delivery schedules supporting aggressive project timelines. Quality certification requirements vary by country, necessitating flexible documentation approaches. Cultural considerations influence relationship building and long-term partnership development.

Central Asian and CIS markets require compliance with GOST standards and Russian language documentation capabilities. Payment terms and logistics considerations reflect regional business practices. Cold climate performance becomes critical for outdoor installations.

Middle Eastern markets demand high-temperature performance and corrosion resistance addressing harsh environmental conditions. Large-scale infrastructure projects require substantial inventory capabilities and technical support resources. Cultural awareness facilitates successful business relationships.

Purchasing Recommendations and Strategic Considerations

Successful procurement begins with comprehensive specification development addressing all technical and commercial requirements. Detailed drawings, material specifications, and performance criteria eliminate ambiguity during supplier evaluation and quotation processes.

Supplier qualification encompasses manufacturing capabilities, quality systems, delivery performance, and technical support resources. Site audits verify production capabilities and quality control procedures. Reference checks with existing customers provide insights into actual performance and service quality.

Quality assurance protocols should include material certificates, dimensional inspections, and pressure testing documentation. Third-party inspection services provide independent verification for critical applications. Packaging and shipping procedures protect product integrity during transportation.

Commercial terms require careful consideration of payment schedules, delivery timelines, and warranty provisions. Price negotiations should balance cost reduction with quality maintenance. Long-term agreements provide supply security while enabling volume discounts.

Technical support availability influences supplier selection, particularly for complex applications or specialized materials. Training programs enhance installation quality and system performance. Emergency support capabilities minimize downtime during unexpected situations.

Conclusion

Selecting optimal buttweld elbows requires balancing technical performance, quality standards, and commercial considerations. Understanding material properties, dimensional requirements, and application-specific factors guides informed decision-making. Regional market characteristics influence supplier selection and procurement strategies.

Quality suppliers provide comprehensive technical support, reliable delivery performance, and competitive pricing. Proper specification development, supplier qualification, and quality assurance protocols ensure project success. Investment in superior fittings reduces lifecycle costs while enhancing operational reliability and safety performance across demanding industrial applications.

FAQ

Q1: What determines the pressure rating of a buttweld elbow?

A: Pressure ratings depend on material grade, wall thickness, temperature conditions, and applicable standards such as ASME B16.9. The elbow's geometry and manufacturing quality also influence maximum allowable working pressure.

Q2: How do I select between long radius and short radius elbows?

A: Long radius elbows provide better flow characteristics and lower pressure drop, ideal for most applications. Short radius elbows suit space-constrained installations where the higher pressure loss remains acceptable for the specific application.

Q3: What material certifications should I require for critical applications?

A: Request mill test certificates, chemical composition reports, mechanical property verification, and dimensional inspection records. Third-party testing documentation provides additional assurance for high-stakes applications requiring maximum reliability.

Partner with JS FITTINGS for Superior Buttweld Elbow Solutions

Choosing the right buttweld elbow supplier impacts project success, operational reliability, and long-term costs. JS FITTINGS brings over 40 years of manufacturing expertise to your most demanding applications. Our comprehensive product range spans carbon steel, stainless steel, and specialty alloy configurations meeting diverse industry requirements.

Advanced production capabilities include four dedicated manufacturing lines producing seamless elbows with consistent quality and dimensional accuracy. ISO 9001, CE, and GOST-R certifications demonstrate our commitment to international quality standards. Competitive pricing reflects efficient operations while maintaining superior product performance.

Our global market experience across Middle East, South America, Europe, and Asia provides valuable insights into regional requirements and preferences. Technical support teams assist with material selection, specification development, and application optimization. Reliable delivery schedules support your project timelines while comprehensive documentation facilitates approval processes.

Whether you need standard configurations or specialized solutions, JS FITTINGS delivers the quality, reliability, and service excellence your projects demand. Our buttweld elbow manufacturer capabilities ensure optimal performance across diverse industrial applications. Contact us at admin@jsfittings.com to discuss your specific requirements and discover how our expertise can enhance your next project.