- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

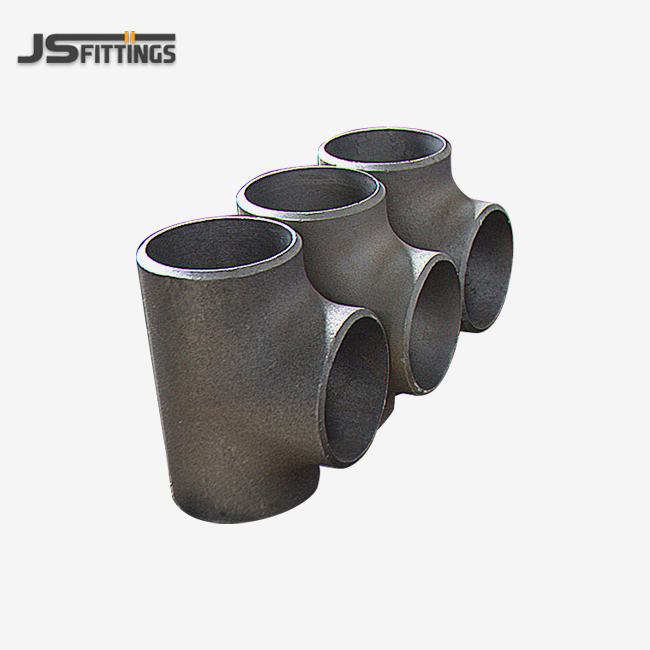

Carbon Steel End Caps from China for Nigeria Pipeline Projects

Carbon steel end caps from Chinese manufacturers offer the ideal combination of quality, durability, and affordability when Nigeria's expanding pipeline infrastructure requires dependable closure options. These important pipeline parts can withstand high pressure and offer reliable corrosion resistance when properly coated or protected. This makes them perfect for Nigeria's networks that distribute oil, gas, and water. Chinese-made pipe end caps follow the ASME B16.9 standards exactly and come with a lot of different certifications. They provide the performance and reliability that Nigerian building projects need.

Understanding Carbon Steel End Caps for Pipeline Projects

Carbon steel end caps are essential pipeline fittings designed to provide a secure closure at the ends of piping systems. When properly welded and installed according to design specifications, they help ensure safe containment of fluids or gases under designated pressure conditions. Manufactured from carbon steel materials primarily composed of iron and carbon, these fittings offer excellent mechanical strength and durability for industrial applications.

Types and Specifications of Pipeline End Caps

Butt-weld end caps are available in various designs to meet different project requirements. Seamless end caps are often preferred for critical or high-pressure applications due to their uniform material structure, while welded end caps provide a cost-effective solution for standard operating conditions. Typical sizes range from ½ inch (DN15) up to 48 inches (DN1200), making them suitable for both small distribution pipelines and large transmission systems.

For Nigerian infrastructure projects, compliance with recognized standards is essential. Carbon steel end caps can be manufactured in accordance with ASME B16.9, EN 10253 standards, depending on project specifications. These standards help ensure dimensional compatibility, mechanical reliability, and international quality acceptance. Wall thickness options commonly range from SCH 10 to XXS to accommodate various pressure ratings and operating conditions.

Material Properties and Surface Protection

Our carbon steel end caps are produced using ASTM A234 material grades, which are specifically developed for pressure piping systems. To enhance corrosion resistance, the base material can undergo surface treatments such as sandblasting followed by protective coatings, including water-based eco-friendly paint or high-performance epoxy coatings. These protective measures are particularly important for Nigeria’s humid tropical climate, where pipelines may be exposed to moisture, salinity, and other environmental challenges.

While carbon steel itself is not inherently resistant to acidic, alkaline, or saline environments, properly applied coatings and corrosion protection systems allow these fittings to perform reliably across coastal areas, industrial zones, and rural infrastructure networks in Nigeria.

Choosing the Right Carbon Steel End Cap: Key Comparison Insights

Selecting the appropriate pipeline end cap requires careful consideration of material properties, operating environment, and project-specific requirements. A clear understanding of these factors enables procurement professionals to balance cost efficiency, safety, and long-term performance.

Carbon Steel vs. Alternative Materials

For cost-sensitive projects, carbon steel end caps offer a significant economic advantage over stainless steel alternatives. While stainless steel provides superior inherent corrosion resistance, carbon steel end caps can deliver reliable performance when protected with suitable coatings or corrosion control systems. This cost-performance balance is particularly valuable for large-scale infrastructure projects in Nigeria, where budget optimization remains a key concern.

Plastic materials such as PVC or HDPE are commonly used in low-pressure water or drainage applications; however, they lack the mechanical strength, temperature resistance, and pressure-bearing capability required for demanding pipeline systems. For oil and gas transmission, water distribution, and industrial process piping where structural integrity and safety are critical, carbon steel end caps remain the preferred solution.

High-Pressure Applications and Safety Considerations

Many Nigerian pipeline projects operate under elevated pressure conditions, requiring fittings designed in accordance with recognized international standards. Carbon steel end caps intended for high-pressure service are manufactured with controlled geometry and wall thickness to ensure uniform stress distribution and reliable performance when welded into the pipeline system.

Quality assurance procedures typically include material verification, dimensional inspection, non-destructive testing where required, and comprehensive documentation such as mill test certificates (EN 10204 3.1). These measures support full traceability and compliance with project specifications commonly adopted in Nigerian infrastructure developments. Robust quality control helps reduce operational risk and gives procurement managers greater confidence in supplier selection.

Procurement Strategies for Carbon Steel End Caps from China

Sourcing carbon steel end caps from China requires a clear understanding of supplier capabilities, quality management practices, and logistics planning. A structured procurement strategy helps maintain product quality, control project timelines, and optimize overall costs for pipeline projects.

Supplier Verification and Quality Assurance

Supplier qualification should include verification of quality management systems, manufacturing capability, and project experience. Reputable manufacturers typically operate under an ISO 9001 certified quality management system and can supply products manufactured in accordance with internationally recognized standards. Where required for specific markets or projects, carbon steel end caps can also be produced to meet applicable CE/PED or EAC (formerly GOST-R) requirements.

Experience in supplying fittings for large-scale energy and infrastructure projects is an important indicator of supplier reliability. Many established Chinese manufacturers have supported projects executed by EPC contractors associated with major oil and gas operators, including those operating under ADNOC frameworks. Such experience demonstrates the ability to meet stringent technical and documentation requirements.

An assessment of production capacity is equally critical. Manufacturers with decades of industry experience and multiple production lines are better positioned to ensure consistent quality, accommodate customized specifications, and meet delivery schedules. This capability is particularly important for large Nigerian infrastructure projects that require high volumes of pipeline fittings.

Order Planning and Logistics Optimization

Minimum order quantities vary depending on size, wall thickness, and specification. For standard small- and medium-diameter carbon steel end caps, MOQs are typically lower, while larger or non-standard items are produced on a project basis. Bulk purchasing can offer cost advantages and improved production scheduling, especially for long-term pipeline developments.

For standard specifications, typical manufacturing lead times range from approximately 15 to 30 days, with extended timelines required for large-diameter or custom-designed end caps. Shipments to Nigerian ports are handled through established international logistics networks, balancing transit time and freight cost. Proper export packaging and container consolidation help protect goods during transport and improve overall shipping efficiency.

Installation and Maintenance of Carbon Steel End Caps on Nigerian Pipelines

Proper installation and maintenance practices are essential to ensure the long-term performance and safety of carbon steel pipeline fittings. By following established engineering guidelines, project teams can minimize installation errors, maintain system integrity, and reduce long-term operating costs.

Installation Best Practices

Effective installation begins with thorough surface preparation. Pipeline ends must be carefully cleaned to remove oxidation, contaminants, and surface irregularities that could compromise weld quality. Proper beveling is critical to ensure adequate weld penetration and sound joint formation in accordance with the approved welding procedure specification (WPS).

During welding, preheating, electrode selection, and post-weld heat treatment should be applied where specified by the applicable material grade, wall thickness, and project standards. All critical welding work should be performed by qualified welders and subject to appropriate inspection methods, such as visual examination and non-destructive testing when required. Common installation issues include inadequate surface preparation, incorrect welding parameters, and insufficient inspection, all of which can negatively affect joint integrity.

Corrosion Prevention and Maintenance

Nigeria’s humid tropical climate presents increased corrosion challenges, making proactive corrosion management essential. Routine inspections should assess coating condition, identify early signs of coating degradation, and verify that fittings remain properly integrated into the pipeline system. Visual inspections, supplemented by non-destructive testing where appropriate, help detect potential issues before they develop into serious defects.

Protective coating maintenance typically includes localized touch-up repairs and full recoating when necessary. When used in conjunction with protective coatings, cathodic protection systems provide additional corrosion control for buried or submerged pipelines. Together, these measures significantly extend service life, reduce unplanned maintenance costs, and help prevent premature system failures.

Our Expertise in Carbon Steel End Caps Manufacturing

Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd (JS FITTINGS) has been making pipeline parts for forty years. By focusing on quality, innovation, and customer happiness, we've built strong relationships with clients in the Middle East, South America, Europe, and Asia.

Comprehensive Product Range and Customization

JS FITTINGS manufactures a full range of butt-weld pipe fittings, with particular expertise in carbon steel end caps for demanding industrial applications. Standard production covers sizes from ½ inch to 48 inches, with multiple wall thickness options designed to suit different pressure classes and operating conditions. In addition to standard products, we offer custom manufacturing services to accommodate non-standard dimensions, alternative material grades, and specific project or approval requirements.

Quality control procedures are implemented throughout the production process to ensure compliance with applicable standards and project specifications. These procedures typically include raw material verification, dimensional inspection, non-destructive testing where required, and surface treatment verification. Comprehensive documentation packages—such as mill test certificates, inspection reports, and compliance statements—are provided to support project quality requirements.

Technical Support and Customer Service

Our engineering team provides professional technical support throughout the procurement and project execution process. From initial specification review to installation guidance and maintenance recommendations, we work closely with customers to ensure proper product selection and application. Support services include direct engineering consultation, detailed technical documentation, and responsive communication channels.

Streamlined ordering procedures help reduce administrative workload, ensure specification accuracy, and support reliable delivery schedules. Through established international logistics partnerships, we supply carbon steel end caps efficiently to Nigerian ports and other global destinations. This integrated service approach supports long-term partnerships built on reliability, transparency, and shared project success.

Conclusion

Chinese carbon steel end caps give Nigerian pipeline projects the best mix of quality, dependability, and low price. If these important parts are properly chosen, installed, and cared for, they will meet strict safety and performance standards and work reliably for decades. Smart buying from licensed makers helps projects succeed and gets the most out of investments by offering great prices on top-quality goods.

FAQ

Q1: How do carbon steel end caps perform in Nigeria's humid climate?

Carbon steel end caps with proper surface treatment exhibit excellent performance in Nigeria's tropical environment. Our specialized coatings, including anti-rust oil, eco-friendly paint, and epoxy systems, provide robust protection against humidity and corrosive conditions. Regular maintenance and inspection protocols further enhance longevity and reliability.

Q2: What are typical lead times for large shipments to Nigeria?

Standard production lead times range from 15 to 30 days, depending on order size and specifications. Custom requirements may require additional processing time. Shipping to Nigerian ports typically adds 20 to 25 days transit time. Our planning team coordinates production and logistics schedules to optimize overall delivery timelines.

Q3: Are complete compliance documents available for Nigerian projects?

We provide comprehensive documentation packages including material certificates, test reports, dimensional verification, and compliance statements. Our products meet ASME B16.9, EN 10253, and GOST standards with full traceability documentation supporting regulatory compliance and project quality assurance requirements.

Partner with JS FITTINGS for Reliable Carbon Steel End Cap Solutions

Ready to secure high-quality carbon steel end caps for your Nigerian pipeline project? JS FITTINGS combines decades of manufacturing expertise with comprehensive product certifications and proven performance across challenging applications worldwide. Our experienced team stands ready to provide customized solutions, competitive pricing, and technical support for your specific requirements. Contact us at admin@chinajsgj.com for detailed quotations and product specifications. To explore our complete range of pipeline fittings and discover why leading contractors trust JS FITTINGS as their preferred carbon steel end cap supplier for critical infrastructure projects.

References

1. American Society of Mechanical Engineers. "ASME B16.9 Factory-Made Wrought Buttwelding Fittings." New York: ASME Press, 2018.

2. Nigerian National Petroleum Corporation. "Pipeline Infrastructure Development Standards and Specifications." Abuja: NNPC Technical Publications, 2019.

3. International Organization for Standardization. "ISO 3183 Petroleum and Natural Gas Industries - Steel Pipe for Pipeline Transportation Systems." Geneva: ISO Publications, 2020.

4. Chen, Wei and Liu, Ming. "Corrosion Performance of Carbon Steel Pipeline Components in Tropical Climate Conditions." Journal of Pipeline Engineering, vol. 45, no. 3, 2021, pp. 78-92.

5. African Development Bank. "Infrastructure Investment Requirements for Nigeria's Oil and Gas Sector 2020-2030." Abidjan: AfDB Economic Research Department, 2020.

6. Zhang, Li and Mohammed, Abubakar. "Quality Assurance Protocols for Chinese-Manufactured Pipeline Components in West African Applications." International Pipeline Conference Proceedings, 2022, pp. 156-171.

Learn about our latest products and discounts through SMS or email