- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

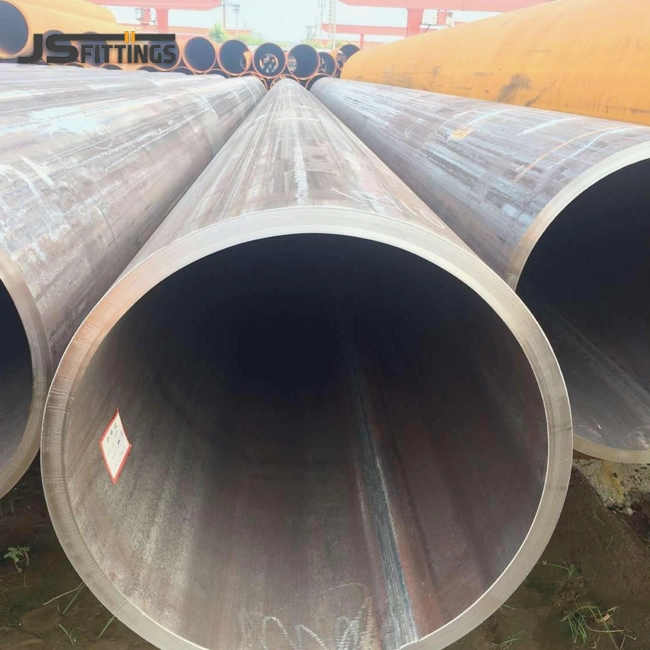

Inside a China Carbon Steel ERW Pipe Factory for EPC Buyers

When industrial project builders and EPC contractors look for dependable carbon steel pipe options, knowing how they are made is important for procurement choices. A China carbon steel ERW pipe factory is more than just a place where things are made; it also has the technical know-how, quality control systems, and supply chain resources that make projects successful. Today's Chinese factories that make ERW pipe use cutting-edge technology and strict quality standards to meet the needs of tough building projects around the world.

Understanding China Carbon Steel ERW Pipes

Manufacturing Process and Key Properties

Electric Resistance Welded (ERW) pipes manufactured in China are produced through an advanced industrial process that forms flat steel strips into cylindrical pipes using high-frequency electrical resistance welding. This process ensures precise dimensional control, uniform wall thickness, and stable product geometry, making ERW pipes suitable for applications requiring consistent measurements and reliable performance.

Modern Chinese ERW pipe manufacturers employ controlled forming and welding technologies to maintain uniform material properties throughout the pipe body. The weld seam is produced under carefully regulated temperature and pressure conditions, resulting in weld integrity and mechanical performance that meet the requirements of applicable international standards. Proper thermal control during welding helps preserve the steel’s mechanical properties and ensures adequate weld penetration.

Standards and Specifications Compliance

Chinese ERW pipes are manufactured in accordance with specific international standards based on their intended application. For pipeline transportation of oil and gas, ERW pipes are produced to comply with API 5L requirements. For structural applications, hollow section pipes are manufactured in accordance with EN 10219 specifications. Each pipe is produced, tested, and certified to the standard specified in the project or purchase order.

Throughout the manufacturing process, quality control procedures are implemented to verify dimensional tolerances, chemical composition, and mechanical properties as required by the relevant standard. Pipes undergo appropriate inspection and testing—such as weld inspection and dimensional verification—before certification and delivery, ensuring consistency and reliability for project use.

Advantages for Large-Scale Infrastructure Projects

China carbon steel ERW pipe factory has a number of useful features that make it especially good for use in EPC projects. Consistent dimensional accuracy simplifies installation and reduces the need for on-site modification, helping contractors maintain construction schedules. The uniform internal surface and controlled geometry support efficient fluid flow performance within designed operating conditions, while precise external dimensions facilitate reliable jointing and connection systems.

In addition, the ERW manufacturing process is cost-effective, allowing manufacturers to supply high-quality pipes at competitive prices. Production flexibility enables a wide range of diameters and wall thicknesses to be manufactured to meet varying project requirements, making ERW pipes a practical and economical choice for diversified pipeline and structural applications.

Inside the Production: Carbon Steel ERW Pipe Manufacturing Process

Raw Material Sourcing and Quality Control

The production of high-quality ERW pipes begins with the careful selection and inspection of raw materials. Chinese ERW pipe manufacturers source hot-rolled steel coils from certified steel mills that maintain strict control over chemical composition and mechanical properties. Incoming material inspection includes verification of mill test certificates, dimensional measurement, and surface quality examination to ensure compliance with specified standards.

Each steel coil is recorded through material traceability systems during production, allowing finished pipes to be traced back to their original steel source. This traceability is essential for projects requiring material certification, quality audits, and full documentation throughout the supply chain.

Forming and Welding Operations

Pipe forming is carried out using precision roll-forming stations that gradually shape flat steel strips into round pipe sections. Controlled forming processes ensure consistent strip alignment and proper edge preparation prior to welding. Forming speed and roll pressure are carefully adjusted to prevent surface defects and dimensional variation.

The longitudinal seam is produced using high-frequency electric resistance welding (HF ERW), where controlled electrical resistance heating brings the strip edges to welding temperature. Welding parameters such as frequency, power input, and squeeze pressure are set according to material specifications and continuously monitored to maintain stable weld quality and penetration throughout production.

Quality Assurance and Testing Procedures

Quality assurance in carbon steel ERW pipe manufacturing involves inspections and tests conducted at multiple stages of production, from raw material receipt to final product release. Non-destructive testing methods, such as ultrasonic inspection of the weld seam, are used to detect internal discontinuities that could affect pipe performance. Hydrostatic pressure testing is performed when required by applicable standards or customer specifications to verify pressure integrity.

Dimensional inspections using calibrated measuring instruments confirm that pipe diameter, wall thickness, and length remain within specified tolerances. Surface quality inspections identify any surface defects or finishing issues that could affect performance or appearance.

These systematic quality control measures ensure that each ERW pipe conforms to relevant standards and customer requirements. Comprehensive inspection records and test documentation provide the evidence needed for project acceptance, regulatory compliance, and third-party verification.

Comparing China Carbon Steel ERW Pipes: How to Choose the Best Supplier

Evaluating Manufacturing Capabilities and Certifications

Careful evaluation of a potential ERW pipe supplier’s manufacturing capabilities and quality certifications is essential for EPC procurement decisions. Production capacity is a key consideration, as infrastructure projects often require stable supply within defined timelines. A factory with an annual capacity of around 30,000 tons can effectively support medium to large infrastructure projects or phased EPC supply requirements without compromising delivery schedules or product consistency.

A manufacturer’s certification profile reflects its commitment to quality management and process control. ISO 9001 certification indicates the implementation of a structured quality management system, while compliance with API and EN standards demonstrates alignment with industry-specific technical requirements. These certifications are subject to regular surveillance and renewal audits to ensure continued conformity with applicable standards.

Price Structure and Commercial Terms

Understanding supplier pricing structures allows EPC buyers to maintain quality requirements while controlling project costs. Direct sourcing from manufacturers can reduce intermediary costs and enable clearer technical communication with production teams. Transparent pricing that reflects raw material costs, production complexity, and order volume supports accurate budgeting and procurement planning.

Minimum order quantities (MOQs) vary depending on production scheduling, steel coil sourcing, and specification changes. Suppliers offering flexible MOQ policies can better accommodate projects of different scales. Payment terms and delivery schedules should align with construction timelines and project cash flow requirements to ensure smooth execution.

Supplier Verification and Risk Mitigation

Effective due diligence when selecting a China carbon steel ERW pipe factory helps identify reliable suppliers and reduce procurement risks. Factory audits provide direct insight into manufacturing processes, quality control systems, and production capacity. Independent third-party inspection services offer objective verification of product quality and standards compliance.

A supplier’s financial stability also affects its ability to fulfill large orders and provide consistent support throughout the project lifecycle. Credit evaluations and reference checks with previous customers are practical tools for assessing supplier reliability and long-term performance.

Practical Guide on Procuring Carbon Steel ERW Pipes from China

Order Placement and Documentation Requirements

Clear specification alignment and comprehensive documentation are the foundation of successful procurement. Technical specifications should clearly define marking requirements, testing standards, material grades, size ranges, and dimensional tolerances. Using detailed specifications, data sheets, and bills of materials (BOMs) helps minimize misunderstandings and ensures accurate pricing.

Purchase orders should clearly define shipping terms, inspection requirements, and acceptance criteria. Early agreement on packaging methods, delivery schedules, and loading plans helps prevent delays and unexpected costs. Export documentation requirements vary by destination country and should be confirmed in advance to ensure customs compliance and smooth clearance.

Logistics and Shipping Considerations

Effective logistics planning protects products while balancing transportation cost and delivery schedules. Optimizing container utilization within weight and safety limits helps reduce freight costs without compromising handling or transport safety. Proper packaging, including end protection and surface safeguards, minimizes damage during loading, transport, and unloading.

Production schedules, container availability, and vessel bookings must be carefully coordinated to meet project timelines. Experienced suppliers maintain close coordination with freight forwarders specialized in steel cargo transportation, supporting consistent and reliable delivery performance to global project sites.

Quality Control and Inspection Strategies

Pre-shipment inspection plays a critical role in verifying product conformity before dispatch. Independent third-party inspection services provide objective verification and documentation to support project acceptance procedures. Inspection scopes typically include dimensional checks, surface condition inspection, weld inspection where applicable, and review of material test certificates and relevant test reports.

Clear communication protocols ensure efficient handling of quality concerns or specification clarifications. Regular production progress updates allow potential issues to be identified early and resolved before they impact delivery schedules or project execution.

JS FITTINGS: Manufacturing Excellence for EPC Applications

Production Capabilities and Technical Infrastructure

Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd (JS FITTINGS) operates advanced production facilities as a China carbon steel ERW pipe factory designed to meet the demanding requirements of EPC contractors and industrial project developers. Our four specialized production lines use modern forming and welding technology to make ERW pipes with great mechanical qualities and consistent dimensional accuracy.

Our ability to produce 100,000+ tons a year means that there is always enough supply for big projects, and we can still be flexible enough to meet urgent shipping needs. The factory uses computer-controlled shaping tools and automatic systems for welding that improve product quality and consistency.

Quality Certifications and Compliance Standards

JS FITTINGS upholds a wide range of quality credentials that show our dedication to global norms and pleasing our customers. ISO 9001 is a standard that helps organizations ensure they are consistently meeting the needs of their customers and other stakeholders while complying with applicable regulations. Our ISO 9001 quality management system helps all of our manufacturing processes get better over time and stay in control. The CE marking and GOST-R approvals let people in Europe and Russia, respectively, buy the products.

Our dual-standard certification method makes sure that API 5L and EN 10219 standards are met by ERW pipes at the same time. This gives EPC buyers the freedom to choose what they want to buy and makes it easier for projects that have to meet more than one standard. Regular audits by people outside of the company make sure that these standards are still being followed and our quality management methods are working.

Specialized Services for EPC Projects

EPC applications have their own needs, and JS FITTINGS understands this. They offer specific services that make it easier to get what you need and install it. With our precision cutting, you get pipe end treatments that are ready to use. This means you don't have to prepare them in the field, and fitting is quicker. Cutting custom lengths reduces waste and helps meet the needs of different projects.

Our oil and gas project transportation system offers unique shipping services in Central Asia and the Middle East, which are areas where many EPC projects need dependable help with their supply chains. Dedicated shipping partners make sure that projects in remote areas are kept on schedule with their transportation and deliveries.

Conclusion

EPC projects count a lot on the reliability and quality of carbon steel ERW pipe suppliers. When you know how Chinese ERW pipes are made, how quality is checked, and how suppliers are found, you can choose a seller wisely and avoid risks. Using high-tech machinery and strict quality control, modern Chinese factories make pipes that meet both global standards and the needs of each project

When you rate a supplier, you should think about their ability to make products, how they are certified, their business terms, and the help they can give with logistics. Clear communication, thorough record-keeping, and preemptive quality control across the entire supply chain are needed for buying to go smoothly.

FAQ

Q1: What are the durability differences between ERW and seamless pipes?

ERW pipes offer comparable durability to seamless pipes for most applications, with proper manufacturing ensuring weld strength equivalent to base material properties. The choice depends on specific pressure requirements, with ERW pipes being suitable for standard to medium-pressure applications, while seamless pipes may be preferred for extremely high-pressure services.

Q2: How do Chinese manufacturers ensure corrosion resistance in ERW pipes?

Corrosion resistance results from careful steel chemistry control, proper surface preparation, and optional protective coatings. Chinese manufacturers utilize steel grades with appropriate alloy content and apply surface treatments such as galvanizing or epoxy coatings based on application requirements.

Q3: What are typical lead times and minimum order quantities from Chinese factories?

Standard lead times range from 4-8 weeks, depending on order size and specifications, with MOQs typically starting at 25-50 tons for standard sizes. Custom specifications may require longer lead times and higher MOQs based on production scheduling requirements.

Q4: How can EPC buyers verify the quality of Chinese ERW pipes?

Quality verification involves reviewing manufacturer certifications, conducting factory audits, implementing third-party inspection services, and requiring comprehensive test documentation. Pre-shipment inspection provides final quality confirmation before product acceptance.

Connect with JS FITTINGS for Reliable Carbon Steel ERW Pipe Solutions

EPC contractors seeking dependable China carbon steel ERW pipe factory partnerships can benefit from JS FITTINGS' four decades of manufacturing excellence and comprehensive project support capabilities. Our dual-standard certifications, precision cutting services, and specialized logistics systems address the unique challenges faced by EPC buyers in today's competitive market environment.

Contact our technical team at admin@chinajsgj.com to discuss your specific project requirements and discover how our China carbon steel erw pipe factory supplier expertise can support your procurement objectives.

References

1. American Petroleum Institute. "Specification for Line Pipe - API 5L." 46th Edition, Washington DC: API Publishing Services, 2018.

2. European Committee for Standardization. "Cold Formed Welded Structural Hollow Sections of Non-alloy and Fine Grain Steels - EN 10219." Brussels: CEN Publications, 2019.

3. Zhang, Wei and Liu, Ming. "Quality Control in Electric Resistance Welded Pipe Manufacturing: Chinese Industry Practices." Journal of Manufacturing Technology, Vol. 45, No. 3, 2020, pp. 112-128.

4. International Organization for Standardization. "Quality Management Systems - Requirements ISO 9001." Geneva: ISO Publications, 2015.

5. Chen, David and Wang, Sarah. "Supply Chain Management in Steel Pipe Manufacturing for Global EPC Projects." Industrial Procurement Quarterly, Vol. 28, No. 2, 2021, pp. 67-84.

6. Asian Steel Pipe Manufacturers Association. "Technical Standards and Best Practices for ERW Pipe Production in Asia." Singapore: ASPMA Publications, 2019.

Learn about our latest products and discounts through SMS or email