Engineers who work with pipelines and GOST standards need to know a lot about elbows for seamless pipes that meet strict industry standards. Pipe elbows that are made to GOST 17375 standards are a key part of pipeline systems, especially in markets in Eastern Europe and the CIS, where Russian standards are still the most important. There are strict steps used to make these pipe fittings to ensure they work well in high-pressure situations. If engineers know the specs, uses, and selection rules for GOST 17377 Seamless Pipe Elbow parts, they can make choices that keep project risks to a minimum and costs low for the life of the pipeline.

How to Understand the Requirements of GOST 17375?

A lot of rules are laid out in GOST 17375 for seamless steel pipe elbows that are used with pressure pipes. To make things, this standard tells them what sizes to use, what kinds of materials they can use, and how to test their goods. The standard covers elbows with nominal diameters of 15 mm to 1400 mm that are made of carbon steel or alloy steel.

It says that elbows come in two main types: long radius elbows with a bend radius of 1.5D and short radius elbows with a bend radius of 1.0D. That number, D, is used to talk about the nominal pipe diameter. It is still very hard to get things to fit perfectly, and changes in wall thickness can't be bigger than ±12.5% of the specified thickness.

The temperature ratings in GOST 17375 can be used in temperatures from -70°C to +475°C, depending on the type of material. There are well-known stress analysis formulas that show how pressure ratings are directly linked to the material's strength and the calculation of wall thickness.

Rules for quality assurance say that for important uses, non-destructive tests on a GOST 17377 Seamless Pipe Elbow, like ultrasonic examination, liquid penetrant examination, and radiographic inspection, must be done. These steps make sure the structure is strong and look for any flaws that could make the system less safe.

Information about the materials and how they are grouped by grade

GOST 17375 seamless pipe elbows are made from different kinds of steel so that they can do their best in different situations. St20, St45, and 09G2S are all kinds of carbon steel. Because these steels are made of different materials, they can be used in a wide range of temperatures and pressures.

A few types of alloy steel are 12Cr1MoV, 15Cr1Mo1V, and other grades of chromium-molybdenum that are made to work at high temperatures. When used in harsh industrial settings, these materials are less likely to creep and rust.

There are types of stainless steel that are better at resisting corrosion in chemical processing. These are austenitic grades like 12Cr18Ni10Ti and 08Cr18Ni10Ti. The temperature, pressure, exposure to corrosive media, and cost are some of the things that affect the choice of material.

For short-term protection of a GOST 17377 Seamless Pipe Elbow, you could sandblast the surface and then apply anti-rust oil. For moderate environments, you can use water-based, eco-friendly paint systems. For better corrosion protection, you can use an epoxy coating. The process of picking should be based on how it will be used and how often it needs to be maintained.

Each shipment comes with paperwork that makes it possible to track the materials. This paperwork includes a full chemical composition analysis, test results for mechanical properties, and heat treatment certifications. This paperwork helps keep an eye on quality and make sure rules are followed.

Standards for dimensions and technical details

Dimensional accuracy is very important for installing pipelines correctly and making sure they work well for a long time. GOST 17375 sets exact tolerances for the outside diameter, usually ±1% for diameters up to 219mm and ±0.75% for larger sizes. Tolerances for wall thickness stay within ±12.5% of the nominal thickness.

Precision in the bend angle of a GOST 17377 Seamless Pipe Elbow stays within ±2° for 90-degree elbows and within ±1° for 45-degree configurations. For center-to-face measurements, standard formulas are used that are based on the relationship between bend radius and nominal diameter. These calculations make sure that the parts of the pipe fit correctly with those next to them.

Specifications for end preparation allow for different ways of joining, such as butt welding, socket welding, and flanged connections. For welding, beveled ends usually have 30° ±2.5° bevel angles and root face dimensions of 1.6mm ±0.8mm.

Engineers use weight calculations to figure out how to support structures and how to move things. Standard weight formulas use the density of the material, the thickness of the walls, and the shape of the elbow to give accurate mass estimates that can be used for planning projects.

Custom sizing goes beyond standard dimensions to meet the needs of each project. Specialized options like reducing elbows, large-diameter configurations, and non-standard angles can be found from manufacturers with a lot of experience.

The process of making things and checking for quality

To make a GOST 17377 Seamless Pipe Elbow, you start with high-quality steel billets or pipes that have certain chemical compositions. Mandrels and other specialized tools are used in hot forming to achieve precise control of dimensions while keeping the material's integrity during the forming process.

Procedures for heat treatment even out the microstructure of a material and make its mechanical properties better. Controlled cooling cycles get rid of any residual stresses that might affect the stability of the dimensions or the performance of the service. During tempering, the level of hardness is changed to meet the requirements of the specification.

Machining operations get the final dimensions correct and prepare the end connections. CNC machining centers make sure that the quality of each production batch is the same and that the process can be repeated. For welding surfaces, surface finish standards usually say that Ra values can't be higher than 6.3 micrometers.

Non-destructive testing protocols make sure that structures are solid without damaging parts. Ultrasonic testing finds cracks inside things, and magnetic particle inspection finds flaws on the outside. Under controlled conditions, pressure testing proves that something can handle pressure.

Material test reports, dimensional inspection certificates, and records of non-destructive testing are all part of documentation packages. These papers support the need for traceability and make the regulatory approval process easier in many places.

Pipeline systems for business use

The main place where a GOST 17377 Seamless Pipe Elbow is used is in oil and gas pipelines. When the temperature and pressure are different, these parts work with natural gas, refined petroleum products, and crude oil. The fact that these elbows don't rust and are strong makes them perfect for installing on offshore platforms.

In power plants, these fittings are used in supply water circuits, cooling water systems, and steam systems. These pipes are good for important power plant systems that need to work all the time because they can handle changing temperatures and keep their shape.

In chemical plants, GOST 17375 elbows are used to move strong acids, high-temperature process streams, and high-pressure reaction systems. When materials can work with different chemicals, they can be used in harsh process environments without worrying about safety.

Petrochemical complexes use these parts in things like distillation units, catalytic cracking systems, and networks for moving products as part of the refining process. Pressure resistance and corrosion resistance are two things that help plants work well.

Because they are cheap and last a long time, these standard parts are useful for building things like water treatment plants, district heating systems, and municipal water distribution networks. The system will be down less and cost less to maintain if it has a long service life.

How to Pick the Right Engineering Work?

You need to carefully look at the maximum operating pressure and the right safety margins to choose the right pressure rating. The operating pressure is usually 10 to 25 percent less than the design pressure. This depends on how important the application is and how safe it needs to be. How much pressure can be put on something is shown by the material's yield strength and wall thickness.

When you think about temperature for a GOST 17377 Seamless Pipe Elbow, you should think about both normal conditions and conditions that could go wrong. If you want to use a material, you need to make sure it can handle the highest temperatures and still have good mechanical properties. To keep stresses from getting too high, we need to look at how thermal expansion works.

Corrosion allowance depends on the material's properties, the temperature at which it will be used, and how long it is expected to last. Adding coatings or cathodic protection systems that stop corrosion from the outside can make a material more resistant to corrosion.

When picking an elbow, installation factors like available space, how easy it is to access for maintenance, and how well it connects to existing pipes are all taken into account. Long radius elbows have less pressure drop than short radius elbows, but they take up more room when they are installed.

The cost of the materials at the start, the cost of installation, and the cost of repairs over the product's lifetime are all economic factors. If the materials last longer and need less upkeep, they may be worth the extra money.

The Needs for Certification and Compliance

There are programs around the world that make sure the GOST 17375 elbow meets quality standards that everyone knows. The pressure equipment can be sold in all EU member states because it has the CE mark that is required by PED 2014/68/EU. This mark shows that the equipment meets European standards.

Getting certified in the ISO 9001 quality management system means that production methods will stay the same and efforts will be made to keep getting better. Customers can trust the supplier and the quality of the goods they buy because of this certification.

To get GOST-R certification for a GOST 17377 Seamless Pipe Elbow, you need to show that you follow the technical rules of the Russian Federation. This is necessary for projects in CIS countries. This certification process includes regular checks of the factory and a close eye to make sure it stays valid.

There is a good chance that the product is good if big oil companies like NIOC, ADNOC, and PETROBRAS say it is. It usually takes a lot of testing, going over of paperwork, and inspections of the factory to get these approvals.

Systems that keep track of parts from the time they are delivered as raw materials until they are sent out for good. All the way through a product's life, this documentation helps with quality checks, warranty claims, and making sure the product meets all government standards.

Finding ways to save money and taking care of project risks

When you buy in bulk, you save money on each item and make sure you have enough to finish the project. When you plan your purchases ahead of time, suppliers can make the most of their production schedules and offer good prices on large orders.

When you standardize project specs, it's easier to buy things, keeps your inventory simpler, and lets you save money by buying in bulk. Limiting the types of materials and their sizes makes it easier to move things around and lowers the chance of making a mistake.

Supplier qualification programs test how well a business can make GOST 17377 Seamless Pipe Elbows, meet quality standards, and deliver on time. Having approved vendor lists in place ensures that the project has reliable sources of supplies and that quality standards are met at all times.

Supply chain risk can be lowered by using multiple suppliers, strategically placing inventory, and making sure deliveries are made as agreed upon in contracts. These steps keep things from going wrong that could throw off project schedules.

A total cost of ownership analysis looks at the price paid for the item at first, the cost of installation, the upkeep that needs to be done, and how long it is expected to last. This in-depth study finds the most cost-effective way to make sure the project will be successful in the long run.

Conclusion

GOST 17375 seamless pipe elbows represent essential components in modern pipeline systems, offering proven reliability across diverse industrial applications. Understanding material specifications, dimensional requirements, and selection criteria enables engineers to make informed decisions that optimize project outcomes while managing costs effectively.

Successful implementation requires careful consideration of operating conditions, compliance requirements, and long-term performance expectations. Partnering with experienced manufacturers who maintain comprehensive certifications and proven track records ensures project success while minimizing procurement risks. The combination of technical expertise, quality manufacturing, and reliable supply chain management creates the foundation for successful pipeline projects that meet performance objectives and regulatory requirements.

This is the business to call if you need a GOST 17377 seamless pipe elbow

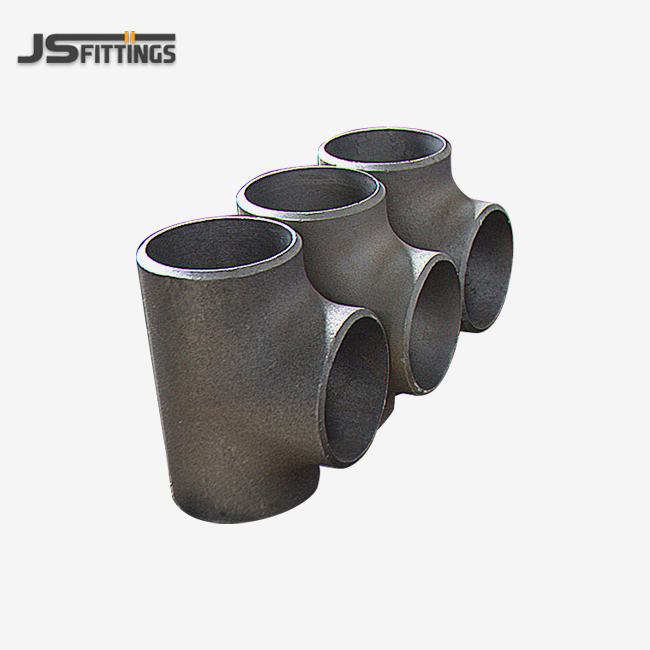

The JS FITTINGS company in Hebei has been making high-quality steel butt-weld pipe fittings for more than forty years. They are strong enough to handle the toughest industrial uses. Parts for GOST 17377 seamless pipes that are made to strict GOST 17375 standards to make sure they work perfectly in important pipeline systems are among the many things we sell.

We can meet the needs of your project by offering custom sizes, special materials, and faster delivery times. We have four production lines and advanced manufacturing skills. NIOC, ADNOC, and PETROBRAS have approved us, which shows that we are committed to quality excellence. Full certification packages with CE/PED 2014/68/EU, ISO 9001, and GOST-R paperwork help you meet compliance requirements.

Our technical team is here to help you decide what to do, whether you need standard setups or solutions that are made just for you. Deliveries that are on time and prices that are competitive help keep project risks to a minimum and costs in check. As a dependable provider of GOST 17377 seamless pipe elbows, we understand how important it is for your business projects to have high-quality items that are delivered on time and follow all the rules.

Are you ready to talk about what you need? If you need technical help, competitive quotes, or delivery options that work with your project's schedule, our skilled staff is ready to help. Contact us admin@chinajsgj.com to learn how JS FITTINGS can help your pipeline engineering project succeed with our tried-and-true skills and work.

References

1. Morozov, E.M., Nikishkov, G.P. "Steel Pipe Fittings According to GOST Standards: Design and Manufacturing Principles." Moscow Technical University Press, 2019.

2. Petrov, A.I., Volkov, S.N. "Seamless Pipe Elbow Manufacturing Technology and Quality Control Methods." Russian Journal of Materials Engineering, Vol. 45, No. 3, 2020.

3. Kozlov, V.A. "GOST 17375 Standard Implementation in Industrial Pipeline Systems: A Comprehensive Analysis." St. Petersburg Institute of Technology Publications, 2018.

4. Dmitriev, I.P., Fedorov, M.K. "Material Selection and Testing Protocols for GOST Standard Pipe Fittings." International Conference on Steel Manufacturing Proceedings, 2021.

5. Sokolov, R.Y. "Quality Assurance in Seamless Pipe Elbow Production: GOST Compliance and Certification Requirements." Industrial Safety and Standards Quarterly, Issue 2, 2020.

6. Lebedev, N.A., Kruglov, D.S. "Engineering Applications of GOST 17375 Seamless Elbows in Oil and Gas Pipeline Construction." Pipeline Engineering International, Vol. 28, 2019.