Pipe end preparation, beveling, and fit-up for butt weld steel pipes

Proper preparation of pipe ends is a critical first step in ensuring a strong and durable butt weld joint. This process involves several key steps:

Cleaning and inspection

Make sure the ends of the lines are clean and free of trash, rust, oil, or dirt before you start to connect them. Check the ends of the lines for damage or cracks that could make the weld less strong. Before moving on, it's important to fix everything.

Precise beveling

The right shape for the weld joint is made by beveling the ends of the pipes. To make sure the weld goes through well and is strong, the root face measurements and bevel angle must be carefully controlled. A bevel angle of 30 to 37.5 degrees is best for most butt weld jobs. Specialized tools can make bevels on pipes that are regular and precise.

Alignment and fit-up

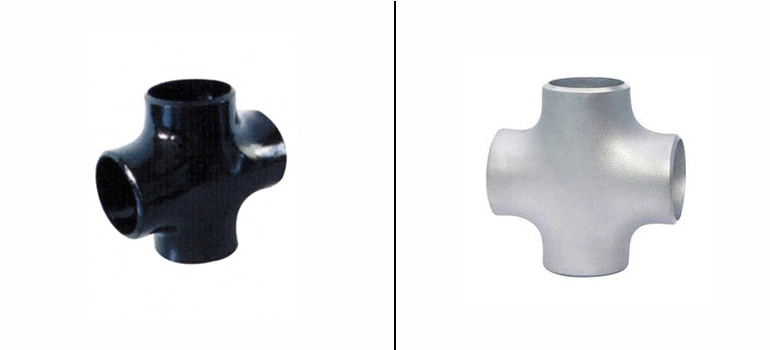

The pipe pieces need to be lined up correctly for the weld to be strong. Use clamps or fittings for adjustment to keep the pipes in place while you spot weld. Stick to the directions for the welding process when setting the root hole, which is the room between the pipe's sides. For butt weld steel pipe crosses, extra care must be taken to ensure all four connections are properly aligned.

Tack welding

Tack welds are used to hold the pipes in place briefly once they are lined up. Around the edge of the joint, there should be an even number of these small welds. Lines that are wider might need more tack welds to stay in place while the main welding is going on.

Welding sequence, heat control, and distortion management in steel pipe work

The welding process itself requires careful planning and execution to ensure a strong, durable joint and minimize distortion:

Welding sequence

A proper welding sequence helps control heat input and reduce distortion. A popular way to do pipe butt welds is to use the "backstepping" method. Instead of welding all the way around in one direction, small pieces are welded around the outside of the pipe in a certain order. When you butt weld steel pipe crosses, it can be harder to make sure that the heat gets to all four points. You may need to plan ahead.

Heat input control

Controlling heat input is crucial for maintaining the mechanical properties of the steel and preventing issues like excessive grain growth or distortion. Welders must carefully monitor and adjust welding parameters such as amperage, voltage, and travel speed to maintain the optimal heat input range specified in the welding procedure.

Interpass temperature management

Maintaining the correct interpass temperature (the temperature of the weld area between passes) is important for controlling the metallurgical properties of the weld and base metal. This may require allowing the joint to cool between passes or using temperature-indicating crayons to monitor the heat.

Distortion control techniques

There will always be some warping in butt weld steel pipe cross-sections because of the limited heating and cooling processes. Some methods for reducing warping are:

- Using proper joint design and fit-up

- Employing balanced welding sequences

- Applying mechanical restraints during welding

- Utilizing back-step welding techniques

- Implementing pre-setting or pre-bending of components

Post-weld inspection, heat-treatment, and support systems to ensure durability

After welding is complete, several important steps are necessary to ensure the long-term durability and performance of the butt welded steel pipes:

Non-destructive testing (NDT)

Several NDT techniques can be used to check the quality and strength of butt welds:

- Visual inspection: Looking at the weld bead for flaws on the surface

- Radiographic testing: looking for problems inside something using X-rays or gamma rays

- Testing with ultrasound: Using sound waves to find problems in the weld

- Magnetic particle testing: Finding flaws on the surface and close to the surface of ferrous materials

- Finding surface-breaking flaws with penetrant testing

Post-weld heat treatment (PWHT)

PWHT may be necessary for certain materials or applications to relieve residual stresses, improve ductility, and enhance the overall durability of the welded joint. The specific heat treatment process will depend on the material properties and service requirements of the piping system.

Proper support and anchoring

Ensuring adequate support for the piping system is crucial for long-term durability. This includes:

- Designing and installing appropriate pipe supports and hangers

- Accounting for thermal expansion and contraction

- Implementing proper anchoring systems to manage forces and movements

- Using expansion joints or loops where necessary

Corrosion protection

Depending on the environment and service conditions, additional corrosion protection measures may be necessary. This could include applying protective coatings, implementing cathodic protection systems, or selecting corrosion-resistant materials for components like butt weld steel pipe crosses.

Documentation and record-keeping

Maintaining detailed records of the installation process, including welding procedures, inspection results, and any post-weld treatments, is essential for future reference and maintenance planning.

Conclusion

Properly installing butt weld steel pipes requires attention to detail at every stage, from initial preparation to final inspection and support. By following these best practices, project managers and engineers can ensure the creation of durable, high-performance piping systems that meet the demanding requirements of industrial applications.

FAQ

1. What are the key factors in selecting the right butt weld steel pipe cross for my project?

When selecting a butt weld steel pipe cross, consider factors such as material compatibility, pressure rating, temperature requirements, and corrosion resistance. Ensure the chosen cross meets all relevant industry standards and project specifications.

2. How often should butt welded pipe joints be inspected in industrial applications?

Inspection frequency depends on the specific application, environment, and regulatory requirements. Generally, periodic visual inspections should be conducted, with more comprehensive NDT performed during scheduled maintenance shutdowns or as dictated by risk-based inspection programs.

3. Can butt weld steel pipe crosses be used in high-temperature applications?

Yes, butt weld steel pipe crosses can be used in high-temperature applications when made from appropriate materials such as high-temperature alloy steels. The specific grade should be selected based on the operating temperature, pressure, and other environmental factors.

4. What are the advantages of using butt weld fittings over threaded or flanged connections?

Butt weld fittings offer several advantages, including stronger joints, better flow characteristics, reduced leak potential, and the ability to withstand higher pressures and temperatures. They also typically require less maintenance and have a lower profile compared to flanged connections.

Quality Butt Weld Steel Pipe Crosses from Trusted Manufacturers | JS FITTINGS

Need butt weld steel pipe crosses that you can trust for your next project? You only need to look at JS FITTINGS. Our wide selection of high-quality pipe fittings, which includes crosses, is made to meet the needs of the toughest industrial settings. You can be sure that our goods will always be of high quality and work well because they have ISO 9001, CE, and GOST-R certifications.

Whether you need stainless steel, duplex steel, or special alloy steel crosses, we have the expertise and production capabilities to meet your requirements. Our corrosion-resistant fittings can withstand harsh environments and corrosive media, ensuring long-lasting performance in your piping systems.

Don't compromise on quality when it comes to critical components like butt weld steel pipe crosses. Contact JS FITTINGS today at admin@chinajsgj.com to discuss your project needs and discover how our competitively priced, high-performance fittings can contribute to the success and durability of your industrial piping systems.

References

1. American Welding Society. (2020). AWS D1.1/D1.1M:2020 Structural Welding Code - Steel. Miami, FL: AWS.

2. American Society of Mechanical Engineers. (2019). ASME B31.3-2018: Process Piping. New York, NY: ASME.

3. Nayyar, M. L. (2000). Piping Handbook (7th ed.). New York, NY: McGraw-Hill Education.

4. American Petroleum Institute. (2018). API Standard 1104: Welding of Pipelines and Related Facilities (22nd ed.). Washington, D.C.: API.

5. Antaki, G. A. (2003). Piping and Pipeline Engineering: Design, Construction, Maintenance, Integrity, and Repair. Boca Raton, FL: CRC Press.

6. Mohinder L. Nayyar. (2017). Piping Systems Manual. New York, NY: McGraw-Hill Education.

_1761034851179.webp)