- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the Key Specifications for ASME B16.9 Fittings?

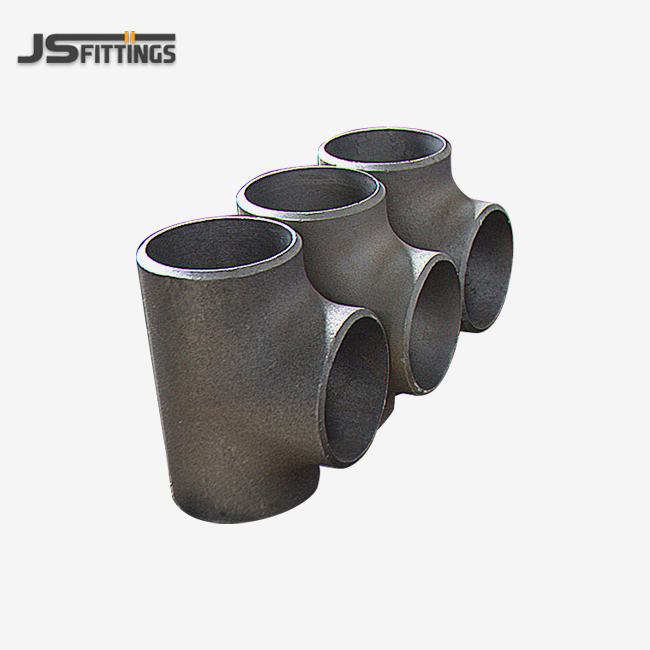

Understanding the comprehensive specifications governing ASME B16.9 Fittings is crucial for engineers, procurement professionals, and project managers involved in industrial piping system design and implementation. The ASME B16.9 standard establishes rigorous requirements for factory-made wrought steel buttwelding fittings, encompassing dimensional tolerances, material properties, pressure-temperature ratings, and quality control procedures that ensure reliable performance in critical applications. These specifications address everything from wall thickness calculations and bend radius requirements to surface finish standards and marking conventions that facilitate proper installation and maintenance. ASME B16.9 Fittings must demonstrate compliance with strict geometric parameters, metallurgical properties, and manufacturing processes that guarantee compatibility with standard piping systems while maintaining structural integrity under demanding operating conditions. The standard's comprehensive approach ensures that certified fittings provide consistent performance characteristics across different manufacturers while meeting the safety and reliability requirements essential for industrial applications ranging from petrochemical processing to power generation facilities.

Dimensional and Geometric Requirements

Wall Thickness and Pressure Ratings

The wall thickness specifications for ASME B16.9 Fittings are calculated using precise mathematical formulas that consider internal pressure, material properties, and safety factors to ensure adequate strength for intended applications. These calculations incorporate the minimum wall thickness requirements at the fitting's critical sections, including the crotch area of tees and the intrados of elbows where stress concentrations are highest. ASME B16.9 Fittings manufactured from materials like ASTM A234 WPB carbon steel must maintain specified wall thickness relationships to the nominal pipe wall thickness, ensuring compatibility with standard piping systems while providing adequate pressure containment. The standard defines pressure-temperature ratings that correspond to different schedule classifications, enabling engineers to select appropriate ASME B16.9 Fittings based on system operating conditions and safety requirements. Quality control procedures include ultrasonic thickness verification at multiple locations to confirm compliance with minimum wall thickness requirements throughout the fitting geometry. Advanced manufacturing processes ensure that ASME B16.9 Fittings maintain consistent wall thickness distribution even in complex geometries like reducing tees and eccentric reducers where material flow during forming operations requires careful control.

Dimensional Tolerances and Geometry

Precise dimensional control represents a fundamental requirement for ASME B16.9 Fittings, with the standard establishing specific tolerance limits for overall dimensions, center-to-end measurements, and angular relationships that ensure proper fit-up with piping systems. The geometric specifications for elbows include precise bend radius requirements, typically 1.5 times the nominal pipe diameter, which optimize flow characteristics while maintaining structural integrity under pressure loading conditions. ASME B16.9 Fittings such as tees and crosses must conform to exact center-to-end dimensions that facilitate accurate piping layout and installation procedures in complex industrial facilities. The standard addresses specific requirements for reducer geometry, including the transition angle limitations and length specifications that ensure smooth flow transition while maintaining adequate structural strength. Dimensional inspection procedures for ASME B16.9 Fittings utilize coordinate measuring machines and precision gauging systems to verify compliance with specified tolerances throughout the manufacturing process. Quality assurance protocols include statistical process control methods that monitor dimensional consistency across production runs, ensuring that ASME B16.9 Fittings maintain interchangeability and compatibility with standard piping components from different manufacturers.

Surface Finish and Marking Standards

Surface finish requirements for ASME B16.9 Fittings address both functional and identification aspects, specifying acceptable surface roughness values and mandatory marking information that facilitates proper installation and traceability. The standard establishes surface preparation requirements that ensure optimal conditions for welding operations, including specific guidelines for surface cleanliness and oxide removal that prevent contamination during installation. ASME B16.9 Fittings must display permanent marking information including material designation, size, schedule, and manufacturer identification that enables verification of specifications during installation and maintenance operations. Surface treatment options for ASME B16.9 Fittings include sandblasting, pickling and passivation, and protective coating applications that enhance corrosion resistance while maintaining dimensional accuracy. The standard specifies acceptable surface discontinuities and repair procedures that ensure structural integrity while permitting reasonable manufacturing variations. Quality control procedures include surface inspection using magnetic particle testing and visual examination to identify surface defects that could compromise fitting performance or welding quality during installation of ASME B16.9 Fittings in critical applications.

Material Properties and Grades

Carbon Steel Material Specifications

Carbon steel ASME B16.9 Fittings manufactured from materials like ASTM A234 WPB demonstrate exceptional mechanical properties and weldability characteristics essential for high-pressure and high-temperature industrial applications. The material specifications address chemical composition limits, including carbon content restrictions that ensure optimal weldability while providing adequate strength and toughness for demanding service conditions. ASME B16.9 Fittings produced from carbon steel grades must meet specific tensile strength, yield strength, and elongation requirements that validate structural integrity under design loading conditions. Heat treatment requirements for carbon steel ASME B16.9 Fittings include normalizing and stress relieving procedures that optimize microstructure and eliminate residual stresses that could compromise long-term performance. Impact testing requirements at specified temperatures ensure that carbon steel ASME B16.9 Fittings maintain adequate toughness characteristics for low-temperature applications commonly encountered in petrochemical and power generation facilities. Quality control procedures include comprehensive material property verification through mechanical testing and chemical analysis that confirms compliance with ASTM specifications throughout the production process.

Stainless Steel and Alloy Materials

Stainless steel ASME B16.9 Fittings manufactured from grades like ASTM A403 WP304L and WP316L provide superior corrosion resistance and elevated temperature performance for demanding chemical processing and pharmaceutical applications. The material specifications address specific requirements for austenitic stainless steel compositions, including controlled carbon content and balanced nickel-chromium ratios that optimize corrosion resistance and mechanical properties. ASME B16.9 Fittings produced from duplex stainless steel grades like UNS S31803 offer enhanced strength characteristics and stress corrosion cracking resistance for aggressive environments encountered in offshore and chemical processing applications. Alloy steel ASME B16.9 Fittings manufactured from materials like ASTM A234 WP11 and WP22 provide elevated temperature strength and creep resistance essential for power generation and high-temperature process applications. Specialized heat treatment procedures for stainless steel and alloy ASME B16.9 Fittings include solution annealing and precipitation hardening processes that optimize material properties for specific service conditions. Quality assurance protocols include corrosion testing, elevated temperature mechanical property verification, and microstructural examination that validate material performance characteristics throughout the specified operating temperature range.

Exotic Materials and Special Applications

Exotic material ASME B16.9 Fittings manufactured from nickel alloys like Inconel, Hastelloy, and Monel address specialized applications requiring exceptional corrosion resistance, high-temperature strength, and compatibility with aggressive chemical environments. These materials demonstrate superior performance in applications where standard carbon and stainless steel grades cannot provide adequate service life or reliability. ASME B16.9 Fittings produced from titanium alloys offer exceptional strength-to-weight ratios and corrosion resistance for aerospace, marine, and specialized chemical processing applications where material performance justifies premium costs. Manufacturing processes for exotic material ASME B16.9 Fittings require specialized equipment, controlled atmospheres, and advanced heat treatment procedures that optimize material properties while preventing contamination or metallurgical degradation. Quality control requirements for exotic material ASME B16.9 Fittings include enhanced testing protocols, material certification procedures, and specialized inspection techniques that validate performance characteristics under extreme service conditions. Custom material specifications can be accommodated for specialized applications where standard grades cannot meet specific performance requirements, with comprehensive engineering support provided to ensure optimal material selection and performance validation.

Manufacturing and Quality Standards

Production Process Requirements

Manufacturing processes for ASME B16.9 Fittings encompass sophisticated forming, machining, and heat treatment operations that require precise control of process parameters to achieve specified dimensional and metallurgical properties. Hot forming operations utilize controlled temperature and pressure conditions to shape fittings from pipe or plate materials while maintaining grain structure and mechanical properties throughout the component geometry. ASME B16.9 Fittings manufactured through seamless forming processes eliminate weld joints that could represent potential failure points in critical applications, particularly important for high-pressure and elevated temperature service conditions. Cold forming operations for smaller diameter ASME B16.9 Fittings require specialized tooling and process control to prevent work hardening and dimensional distortion while achieving specified geometric requirements. Machining operations for ASME B16.9 Fittings include precision end preparation, dimensional finishing, and surface preparation procedures that ensure optimal conditions for field welding and installation. Advanced manufacturing facilities utilize computer-controlled equipment and automated inspection systems to maintain consistent quality and dimensional accuracy throughout the production of ASME B16.9 Fittings across different sizes and configurations.

Heat Treatment and Metallurgical Control

Heat treatment procedures for ASME B16.9 Fittings are carefully controlled to optimize mechanical properties, relieve forming stresses, and ensure metallurgical consistency throughout the component cross-section. Normalizing treatments restore uniform grain structure and mechanical properties that may have been affected during forming operations, particularly important for maintaining consistent performance characteristics in critical applications. ASME B16.9 Fittings requiring stress relief heat treatment undergo carefully controlled heating and cooling cycles that minimize residual stresses while maintaining specified hardness and strength properties. Controlled atmosphere furnaces prevent oxidation and contamination during heat treatment of ASME B16.9 Fittings, ensuring surface quality and dimensional accuracy that facilitate subsequent processing and installation operations. Metallurgical testing procedures include microstructural examination, hardness testing, and grain size analysis that verify proper heat treatment effectiveness and material property development. Quality control systems monitor furnace performance, temperature uniformity, and cooling rates to ensure consistent heat treatment results for ASME B16.9 Fittings throughout production runs and different material grades.

Testing and Inspection Protocols

Comprehensive testing and inspection protocols for ASME B16.9 Fittings encompass dimensional verification, material property validation, and non-destructive examination procedures that ensure compliance with standard requirements and customer specifications. Hydrostatic testing procedures apply specified test pressures to validate pressure containment capability and identify potential defects that could compromise fitting integrity under service conditions. ASME B16.9 Fittings undergo dimensional inspection using coordinate measuring machines and precision gauging systems that verify compliance with specified tolerances and geometric requirements throughout the component geometry. Non-destructive testing methods including magnetic particle inspection, penetrant testing, and ultrasonic examination identify surface and subsurface discontinuities that could affect fitting performance or installation quality. Material property verification includes tensile testing, impact testing, and hardness measurement that confirm compliance with specified mechanical property requirements for different material grades and heat treatment conditions. Quality documentation systems provide comprehensive traceability for ASME B16.9 Fittings including material certificates, test reports, and inspection records that facilitate project compliance and regulatory approval processes.

Conclusion

The key specifications governing ASME B16.9 Fittings encompass comprehensive requirements for dimensional accuracy, material properties, and manufacturing quality that ensure reliable performance in critical industrial applications. These specifications address dimensional tolerances, pressure ratings, material grades, heat treatment procedures, and testing protocols that collectively validate fitting suitability for demanding service conditions. Understanding these requirements enables informed selection and procurement of ASME B16.9 Fittings that meet project specifications while ensuring long-term reliability and safety performance.

FAQ

1. What dimensional tolerances apply to ASME B16.9 Fittings?

ASME B16.9 Fittings must comply with specific dimensional tolerances including center-to-end measurements (±1.6mm for sizes up to 24"), outside diameter tolerances, and wall thickness requirements that ensure proper fit-up with standard piping systems while maintaining structural integrity under pressure loading conditions.

2. Which material grades are commonly used for ASME B16.9 Fittings?

Common material grades for ASME B16.9 Fittings include carbon steel ASTM A234 WPB, stainless steel ASTM A403 WP304L/316L, and alloy steel ASTM A234 WP11/WP22, each offering specific mechanical properties and corrosion resistance characteristics suitable for different industrial applications and operating conditions.

3. What testing requirements apply to ASME B16.9 Fittings?

ASME B16.9 Fittings undergo comprehensive testing including hydrostatic pressure testing, dimensional inspection, material property verification, and non-destructive examination to validate compliance with standard requirements and ensure reliable performance under specified operating conditions.

4. How are ASME B16.9 Fittings marked for identification?

ASME B16.9 Fittings must display permanent marking including material designation, nominal size, schedule classification, manufacturer identification, and heat number that enables traceability and verification of specifications during installation, inspection, and maintenance operations throughout the service life.

Premium ASME B16.9 Fittings Manufacturers | JS FITTINGS

With over 40 years of manufacturing excellence, JS FITTINGS operates a state-of-the-art facility spanning 35,000 m² with 4 advanced production lines delivering 30,000 tons annually of precision-engineered ASME B16.9 Fittings that exceed international standards. Our comprehensive certifications including ISO 9001, CE, PETROBRAS, and approvals from NIOC and ADNOC validate our commitment to uncompromising quality across oil & gas, petrochemical, and industrial sectors. We specialize in manufacturing high-performance ASME B16.9 Fittings from premium materials including carbon steel, stainless steel, and exotic alloys that meet the most demanding specifications through continuous process improvement and advanced manufacturing technologies. Experience the difference that four decades of expertise makes - contact our technical specialists at admin@chinajsgj.com for customized ASME B16.9 Fittings solutions that deliver exceptional performance and reliability.

References

1. American Society of Mechanical Engineers. ASME B16.9-2018: Factory-Made Wrought Buttwelding Fittings. New York: ASME Press, 2018.

2. ASTM International. ASTM A234/A234M-19: Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel. West Conshohocken: ASTM International, 2019.

3. ASTM International. ASTM A403/A403M-19: Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings. West Conshohocken: ASTM International, 2019.

4. American Society of Mechanical Engineers. ASME B31.3-2018: Process Piping Code. New York: ASME Press, 2018.

5. Nayyar, Mohinder L. Piping Handbook. 8th Edition. New York: McGraw-Hill Education, 2019.

6. Mohitpour, M., Golshan, H., and Murray, A. Pipeline Design & Construction: A Practical Approach. 4th Edition. New York: ASME Press, 2017.

Learn about our latest products and discounts through SMS or email