- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

A106 Seamless steel pipes

2. Dual-standard certified steel pipes | API 5L + EN 10219 dual compliance assurance

3. Precision Cutting Services | Ready-to-use pipe end treatments

4. Oil and Gas Project Logistics System | Exclusive Shipping Solutions Covering Central Asia/Middle East

5. Compliant with International Standards: ASTM、ASME、API 5L/6CT、DIN、EN, ISO、JIS、GOST

A106 Seamless Steel Pipes

Product Overview

Our A106 Seamless steel pipes meet ASTM A106/ASME SA106 standards, specifically engineered for high-temperature service applications up to 800°F (425°C). These seamless carbon steel pipes eliminate weak points associated with welded joints through precision extrusion manufacturing. You get superior metallurgical consistency with killed steel construction containing minimum 0.10% silicon content for enhanced resistance to graphitization. Our 30,000-ton annual production capacity ensures reliable supply for your large-scale industrial projects requiring pressure ratings up to 2,000 psi.

Key Features & Advantages

Dual-Standard Compliance: ASTM A106 and ASME SA106 certified pipes meet international quality requirements for critical infrastructure projects.

30,000-Ton Production Guarantee: Our advanced production lines ensure stable supply for bulk industrial orders without delivery delays.

Precision-Engineered Construction: Seamless manufacturing eliminates longitudinal seams, providing uniform wall thickness and superior pressure resistance.

Ready-to-Install Processing: Professional cutting services and precision-machined pipe ends reduce your installation time and labor costs.

Global Logistics Network: Dedicated shipping solutions for Central Asia and Middle East markets ensure timely project delivery.

Technical Specifications

|

Parameter |

Grade B (Most Common) |

Standard / Note |

|

Silicon (Si) |

0.10% min |

Essential for high-temp deoxidation |

|

Tensile Strength |

≥ 415 MPa (60,000 psi) |

ASTM A370 |

|

Yield Strength |

≥ 240 MPa (35,000 psi) |

ASTM A370 |

|

Max. Temperature |

800°F / 427°C |

ASME B31.3 Stress Tables |

|

Deoxidation |

Fully Killed Steel |

ASTM A106 Requirement |

|

Certification |

Triple Certified (A106B/A53B/API 5L B) |

Upon Request |

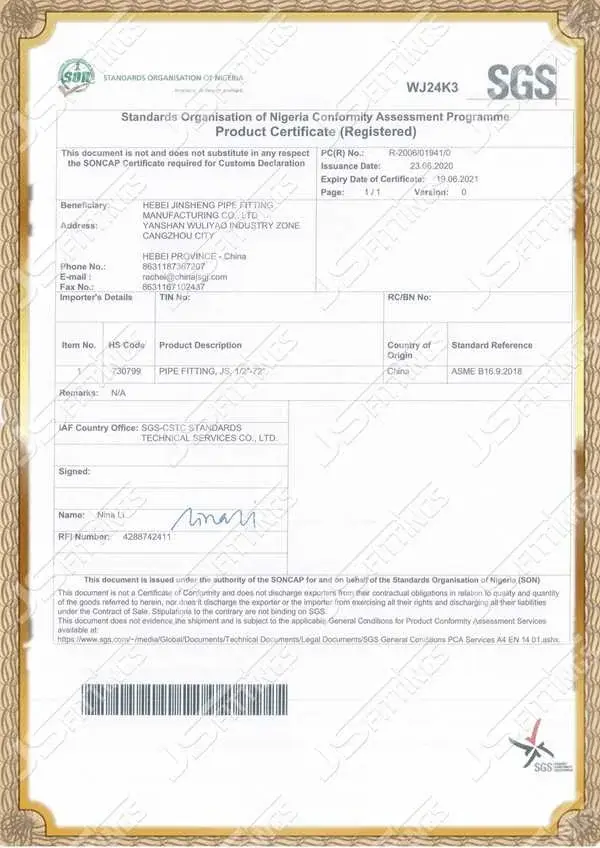

Standards & Certifications

While we specialize in ASTM/ASME standards, our production facility can also manufacture to DIN, EN, and API 5L specifications to meet diverse project requirements.All products carry ISO 9001, CE, and GOST-R certifications with complete material traceability documentation.

Chemical Composition & Mechanical Properties

Grade B (High-Temperature Standard):

Carbon: 0.30% max

Manganese: 0.29–1.06%

Silicon: 0.10% min (Essential for high-temperature stability)

Tensile Strength: ≥ 415 MPa (60,000 psi)

Yield Strength: ≥ 240 MPa (35,000 psi)

Hardness: Max 187 HB

Grade C (High Strength):

· Enhanced carbon and manganese content

· Yield Strength: 275 MPa min

· Requires careful welding procedures

Manufacturing Process

Our 42-year manufacturing expertise combines traditional seamless pipe production with modern quality control. The Hot Finished Seamless creates uniform grain structure throughout the pipe wall. Our 100-meter automated painting lines and eco-friendly sandblasting systems ensure consistent surface preparation for optimal coating adhesion.

Surface Finish & Coating Options

Standard finishes include black lacquer coating and anti-corrosion oil treatment. Hot-dip galvanizing available for applications requiring enhanced external corrosion resistance. Custom surface treatments can be applied based on your specific environmental requirements.

Certificates

Our commitment to quality is backed by internationally recognized certifications:

- ISO 9001:2015

- CE Marking

- GOST-R

- API 5L (for oil and gas applications)

These certifications validate our dedication to producing top-tier products that meet global industry standards.

Applications

Power Generation: High-pressure steam lines in thermal and nuclear plants where thermal cycling resistance prevents fatigue cracking.

PetroChemical Refineries: Process piping for crude oil, refined products, and aggressive gases at elevated temperatures.

Oil & Gas Infrastructure: Compressor stations and offshore platforms requiring pressure resistance above 2,000 psi.

Marine & Shipbuilding: Critical piping systems exposed to harsh marine environments requiring seamless construction reliability.

Packaging & Delivery

Pipes are bundled with protective end caps and wrapped for international shipping. Our dedicated logistics network provides container loading and documentation services. Standard delivery terms include FOB, CIF, and CFR options with full export documentation support.

Customization Service

We provide custom cutting, threading, and beveling services to meet your exact specifications. Special length requirements, non-standard wall thickness, and project-specific testing can be accommodated through our engineering support team.

Quality Control

Each pipe undergoes 100% hydrostatic testing (up to 2500 psi upon request) and dimensional verification. We provide full traceability with Heat Numbers stenciled on every length and MTC to EN 10204 3.1 provided for every batch.

Customer Reviews

"I am thoroughly impressed with the quality of the seamless pipe fittings provided by JS FITTINGS. Each piece we've received has been meticulously crafted, displaying a standard of workmanship that is truly top-notch."

"Their team has demonstrated a remarkable ability to meet tight deadlines without compromising on the quality of their products. The delivery was equally impressive – it arrived earlier than anticipated."

FAQ

Q: What's the difference between A106 and A53 pipes?

A: A53 covers both seamless and welded pipes for general use. A106 Seamless Steel Pipes are specifically designed for high-temperature service with superior metallurgical properties.

Q: Can these pipes be galvanized?

A: Yes, though typically supplied with black lacquer finish, hot-dip galvanizing is available for applications requiring external corrosion resistance.

Q: What's the maximum operating temperature?

A: ASME B31.3 codes permit use up to 800°F (425°C). Above this temperature, alloy steels are recommended.

Q: What makes killed steel different?

A: Killed steel is completely deoxidized with silicon addition, preventing gas pockets and ensuring uniform steel quality compared to rimmed steel.

Contact Us

Get professional technical support and competitive pricing for your A106 Seamless Steel Pipes project requirements at admin@jsfittings.com today.

Learn about our latest products and discounts through SMS or email