- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Carbon Steel SMLS Pipe

2. Dual-standard certified steel pipes | API 5L + EN 10219 dual compliance assurance

3. Standards: ASTM A53 B, ASTM A106 Gr. B, ASTM A179, ASTM A192, ASTM A333 and API 5L Gr B to X70

4. Coatings: Depending on client requests, 3PE, FBE, and Zinc Coating will be applied.

5. JSFITTINGS offers high-quality and competitive prices for seamless and welded steel pipes for the industry pipeline system.

Industry Carbon Steel Pipes

JSFITTINGS offers a comprehensive carbon steel pipe portfolio adhering to major international standards. This includes API 5L steel pipes for oil and gas transmission, ASTM A106 Grade B steel pipes for high-temperature service, ASTM A53 Grade B steel pipes for general piping systems, ASTM A252 Grade 3 pipes for piling applications, and ASTM A333 Grade 6 steel pipes for low-temperature environments. Our product range encompasses seamless and welded (ERW, LSAW, SSAW) steel pipes, coated steel pipes, engineered to meet the rigorous demands of various industrial applications, from mining and construction to water, oil, and gas transmission.

Explore our steel pipe product lines

Key Takeaways

JSFITTINGS provides a wide array of Carbon Pipe & Tube products, perfect for demanding applications in refineries, power plants, and more, with a focus on quality and versatility in heavy wall pipes.

Materials & Grades

Our Carbon Steel SMLS Pipe is available in various grades to suit different applications:

- ASTM A106 (Grades A, B, C)

- ASTM A53 (Grade B)

- API 5L (Grades B, X42, X52, X60, X65, X70)

- Custom grades upon request

Dimensional Tolerance Checks(Per ASTM A530/API 5L)

|

Parameter |

Tolerance |

Instrument Used |

|

Outer Diameter(OD) |

±1%of nominal OD (or±0.79mm) |

Pi tape/Laser micrometer |

|

Wall Thickness(WT) |

±12.5%(SCH40 and below) |

Ultrasonic thickness gauge(UTG) |

|

Length |

±3mm for random,±6mm for cut-length |

Calibrated tape measure |

|

Straightness |

≤0.2%of total length |

Optical comparator |

|

Bevel Angle (for welding) |

30°-35°(±5°) |

Bevel protractor |

Applications

Our product finds extensive use across various industries:

- Oil and gas transportation

- Petrochemical processing

- Power generation plants

- Construction and infrastructure

- Water treatment facilities

- HVAC systems

- Shipbuilding

Visual &Surface Inspection

·Defect Identification:

o Lamination- Check for delamination near pipe ends

o Scratches/Dents -Max 5%of WT depth allowed (per ASME B31.3)

o Rust &Mill Scale-Controlled by SSPC-SP6(Commercial Blast Cleaning)

● Method:

o White light inspection(10,000 lux minimum)

o Dye penetrant test(PT)for surface cracks

Quality Control

At Hebei Jinsheng, quality is our top priority. Our Carbon Steel SMLS Pipe undergoes rigorous testing:

- Hydrostatic pressure testing

- Ultrasonic inspection

- Chemical composition analysis

- Mechanical property testing

- Visual and dimensional inspection

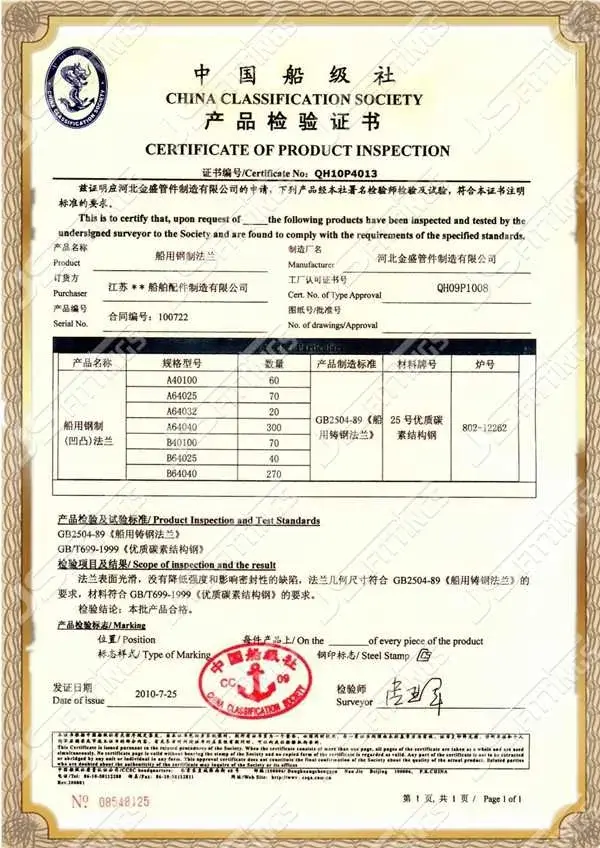

Certificates

Our product meets international quality standards:

- ISO 9001:2015 certified

- API 5L certification

- CE marking

- GOST-R certification

- Mill Test Certificates (MTC) provided with each shipment

Here are other reasons why we're your best bet:

- 36 years of experience in manufacturing and supplying carbon steel seamless and welded steel pipes and fittings.

- We're ISO, CE, and GOST-R-certified; we're 100% legit.

- More than 100 happy customers worldwide. We have made products for companies in Russia, Thailand, the UAE, Oman, Nigeria, etc.

- We're expanding fast. We currently have 5+ production lines and 100,000 square feet of factory space ready to serve you.

- Qualified products. Experienced QC team and strict QC process to ensure your export quality.

- We're fast and responsive. Connect with us on our site, and we'll get back to you within 2 hours.

- We had cooperated with many national oil companies such as ADNOC, PETROBRAS, and CNPC, etc.

FAQ

Q: Where is your factory?

A: Factory of RAYOUNG is in the base of Chinese pipe fittings, Yanshan county, Cangzhou City, Hebei Province. contact us to get the visit brochure.

Q: What is the minimum order quantity (MOQ) for your fittings?

A: Our standard MOQ is 100 pieces, but we can accommodate smaller orders for specialty items.

Q: What is your annual production?

A: The output is 1000 tons / month, almost export of 35-40 containers per month, annual output more than10000 tons.

Q: Can you provide custom fittings based on specific project requirements?

A: Yes, we offer custom fabrication services to meet your unique specifications.

Q: What is the typical lead time for standard fittings?

A: Our standard lead time is 2-3 weeks, depending on the order volume and complexity.

Q: Do you offer technical support for product selection and installation?

A: Absolutely! Our team of experienced engineers is available to provide guidance throughout your project.

Q: Are your fittings suitable for low-temperature applications?

A: Yes, we offer special grades like ASTM A420 WPL6 for low-temperature service.

Q: Do you have distributors in my country?

A: We have stable distributors in Russia, Thailand, UAE, Nigeria, South Africa, Iran and other countries. If you can't import by yourself, we will be glad to introduce you to our customers.

Contact Us

Ready to explore our Industry Carbon Steel Pipe solutions? Our team is here to assist you:

- Email: admin@chinajsgj.com

- Tel/whatsapp: +8618003119682

Contact us today for a quote or to discuss your project requirements. Trust Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd. for all your product needs – where quality meets innovation.

Learn about our latest products and discounts through SMS or email

_1758005569089.webp)