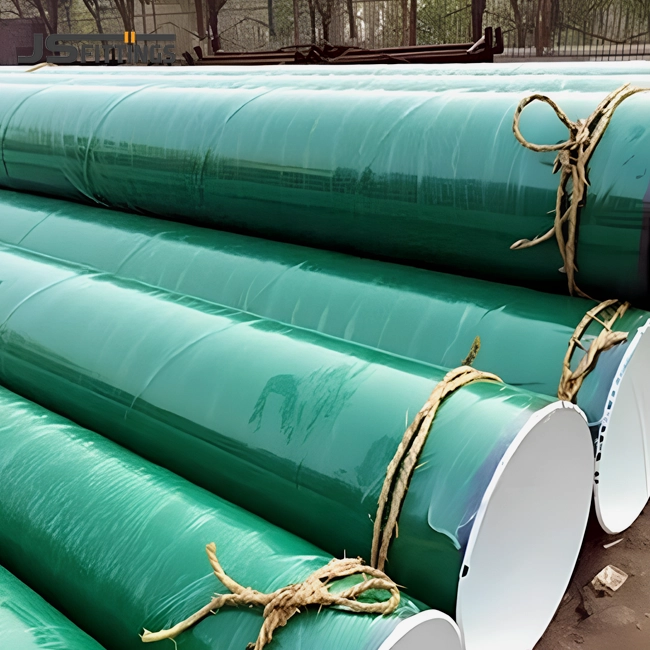

Selecting the right Large Diameter Steel Pipe Fittings for heavy-duty development ventures has gotten to be more important than ever. These specialized components serve as the spine of major foundation advancements, from oil refineries and control plants to water treatment offices and mechanical complexes. The request for vigorous, dependable pipe fittings is expected to develop over Latin America, Southeast Asia, Africa, and the Middle East, where gigantic infrastructure projects are changing whole districts. Quality expansive distance across fittings guarantees consistent associations in pipeline frameworks, minimizing downtime dangers while keeping up ideal stream characteristics. Cutting-edge fabricating strategies have advanced to convey prevalent erosion resistance, upgraded weight evaluations, and amplified benefit life, making these components fundamental for any genuine development endeavor.

Understanding the Critical Importance of Large Diameter Pipe Fittings

Heavy-duty development ventures require components that can withstand extraordinary weights, temperature fluctuations, and destructive situations. Large diameter steel pipe fittings play a significant part in guaranteeing venture victory by giving secure, leak-proof associations that maintain basic integrity over decades of operation. EPC temporary workers and mechanical venture designers recognize that choosing substandard fittings can lead to disastrous disappointments, expensive delays, and security hazards.

The financial impact of fitting disappointments extends distant past starting installation costs—spontaneous shutdowns in mechanical offices can take a toll of hundreds of dollars per hour, whereas pipeline bursts pose critical environmental and security dangers. This reality drives acquisition supervisors to prioritize quality over short-term secured funds when selecting welded pipe fittings and consistent pipe fittings for their projects.

Modern mechanical channeling frameworks work beneath progressively demanding conditions, with pressure evaluations regularly surpassing 1500 PSI and temperatures running from sub-zero situations to extraordinary warm, requiring pipe fittings fabricated from premium materials with exact building resistances that guarantee dependable execution throughout the lifecycle.

Essential Selection Criteria for Premium Large Diameter Fittings

Selecting the ideal large diameter steel pipe fittings requires cautious assessment of numerous components that straightforwardly affect venture results. Fabric composition stands as the essential thought, with carbon steel fittings advertising great strength-to-cost ratios for standard applications, whereas stainless steel fittings give predominant erosion resistance in challenging environments.

Manufacturing guidelines and certifications give pivotal approval of item quality—ISO 9001 certification guarantees reliable generation forms, ASME B16.9 compliance ensures dimensional precision and weight evaluations, and CE stamping or GOST-R certification encourages worldwide exchange and administrative compliance over differing markets.

Delivery of unwavering quality and supply chain steadiness has become progressively vital considerations, as wholesalers and trading companies require providers who can keep up steady stock levels while assembly aggressive extend timelines, raising the significance of established producers with demonstrated track records and strong production capabilities.

Technical details must adjust with venture necessities—pipe elbows, pipe tees, and pipe reducers each serve particular capacities within pipeline frameworks, and their determination impacts generally framework execution, whereas divider thickness, dimensional resistances, and surface wrap up quality all contribute to long-term unwavering quality and support requirements.

Top 5 Large Diameter Steel Pipe Fittings for 2025

Heavy-Duty Carbon Steel Butt Weld Elbows

Carbon steel butt weld elbows speak to the gold standard for directional changes in expansive breadth pipeline frameworks. These components exceed expectations in applications requiring strong quality combined with cost-effective estimating, making them perfect for medium and small design firms overseeing tight venture budgets.

Key advantages include:

- Exceptional weight handling capabilities up to 3000 PSI

- Seamless integration with existing pipeline infrastructure

- Superior weld quality that kills powerless points

- Wide temperature run compatibility from -29°F to 800°F

- Compliance with ASTM A234 WPB specifications

- Cost-effective arrangement for large-scale projects

- Minimal support prerequisites over 25+ years of benefit life

Manufacturing accuracy guarantees steady divider thickness conveyance, avoiding stress concentration focuses that may lead to untimely failure. The consistent development dispenses with potential spill ways while giving smooth inside surfaces that optimize stream characteristics and decrease weight losses.

These butt weld fittings are especially important in government framework ventures where long-term unwavering quality and compliance with delicate necessities take priority. The standardized measurements encourage simple substitution and upkeep, lessening add up to taken the burden of proprietorship all through the lifecycle.

Stainless Steel Large Bore Tees

Stainless steel large bore tees provide unmatched corrosion resistance for demanding industrial applications, large diameter steel pipe fittings. These components excel in chemical processing, marine environments, and food-grade installations where contamination prevention is paramount.

Notable benefits include:

- Outstanding erosion resistance in cruel chemical environments

- Hygienic surface wrap up appropriate for nourishment and pharmaceutical applications

- Excellent quality maintenance at hoisted temperatures

- Long-term has taken a toll on viability despite the higher introductory investment

- Compliance with ASTM A403 review specifications

- Minimal surface unpleasantness for ideal stream characteristics

- Resistance to stretch erosion cracking

The austenitic structure of 316L stainless steel provides exceptional toughness while maintaining excellent formability during manufacturing. This combination enables the production of complex geometries without compromising structural integrity or introducing residual stresses.

Industrial end users and factories benefit from reduced maintenance costs and extended service intervals. The non-reactive surface prevents product contamination in food processing applications while eliminating the need for protective coatings in corrosive environments.

Alloy Steel High-Pressure Reducers

Alloy steel reducers deliver superior performance in high-temperature, high-pressure applications where standard carbon steel components would fail. These specialized fittings incorporate chromium, molybdenum, and other alloying elements that enhance strength and temperature resistance.

Primary advantages encompass:

- Enhanced crawl resistance at temperatures surpassing 1000°F

- Superior strength-to-weight proportion compared to carbon steel alternatives

- Excellent weakness resistance beneath cyclic stacking conditions

- Improved affect sturdiness at low temperatures

- Compliance with ASTM A234 WP11, WP22, and WP91 grades

- Extended benefit life in requesting applications

- Reduced divider thickness requirements due to improved strength

These reducers prove essential in power generation facilities, petrochemical plants, and refineries where extreme operating conditions challenge conventional materials. The enhanced metallurgy provides safety margins that prevent catastrophic failures while maintaining dimensional stability under thermal cycling.

EPC contractors appreciate the reliability these components provide in critical applications large diameter steel pipe fittings. The proven performance record in demanding environments reduces project risk while ensuring compliance with stringent safety standards and regulatory requirements.

Seamless Carbon Steel Pipe Caps

Seamless carbon steel pipe caps provide reliable termination solutions for large diameter pipeline systems. These components eliminate welded seams that could become failure points while providing cost-effective end closure for temporary or permanent applications.

Distinctive features include:

- Seamless development disposes of potential spill paths

- Uniform divider thickness dispersion for reliable strength

- Easy establishment without specialized welding procedures

- Excellent resistance to inner pressure

- Compliance with ASME B16.9 dimensional standards

- Cost-effective arrangement for pipeline termination

- Suitable for both brief and lasting installations

The manufacturing process involves hot forming from solid steel billets, creating a homogeneous structure without weld zones or heat-affected areas. This seamless construction provides superior reliability compared to fabricated alternatives while maintaining consistent mechanical properties throughout the component.

Local installers and engineering firms value the simplified installation procedures these caps offer. The standardized dimensions ensure compatibility with existing pipeline systems, while the robust construction provides long-term sealing integrity without ongoing maintenance requirements.

Heavy-Wall Socket Weld Couplings

Heavy-wall socket weld couplings excel in applications requiring maximum strength and vibration resistance. These components provide secure connections for large diameter pipes while accommodating thermal expansion and mechanical stresses common in industrial applications.

Key performance characteristics include:

- Superior weariness resistance beneath vibrational loading

- Enhanced divider thickness for extraordinary weight applications

- Precise machined attachment measurements for ideal fit-up

- Excellent weld infiltration characteristics

- Compliance with ASME B16.11 specifications

- Reduced establishment time compared to butt weld alternatives

- Superior quality over a shorter distance across applications

The socket design provides positive pipe positioning during installation, while the heavy wall construction accommodates deep weld penetration. This combination creates joints that often exceed the strength of the base pipe material, ensuring long-term reliability in demanding applications.

These couplings prove particularly valuable in retrofit and repair applications where space constraints limit access for butt welding procedures on large diameter steel pipe fittings. The socket design simplifies alignment while providing consistent weld quality regardless of installer skill level.

Regional Market Analysis and Compliance Requirements

Understanding territorial showcase characteristics demonstrates significant for fruitful huge distance across steel pipe fitting acquisition. Latin American markets prioritize cost-effectiveness while keeping up with worldwide quality guidelines, with nations like Brazil and Mexico emphasizing local sourcing needs that favor territorial fabricating capabilities or partnerships.

Canadian markets center on cold climate execution and CSA compliance, requiring fittings with upgraded low-temperature sturdiness, warm stun resistance, and strict fabric traceability. African foundation ventures confront special calculated challenges that advantage providers with solid dissemination systems and neighborhood support, whereas the focus on innovation exchange and skills advancement makes opportunities for territorial collaboration.

Southeast Asian markets appear to have quick mechanical development and require high-quality fittings meeting European and American details, with nations like Vietnam, Thailand, and Indonesia implementing rigid quality necessities.

Central Asian and CIS nations keep up inclinations for GOST-R certified items with demonstrated unwavering quality, reflecting the basic significance of vitality foundation.

Middle Eastern markets prioritize erosion resistance and high-temperature execution, favoring premium-quality components that minimize lifecycle costs beneath cruel natural and mechanical conditions.

Purchasing Recommendations and Strategic Considerations

Successful procurement of large diameter steel pipe fittings requires balancing multiple factors that impact both immediate project needs and long-term performance. Quality certification should take precedence over initial cost savings, as the expense of premature failure far exceeds the savings from purchasing inferior components.

Supplier selection criteria should include manufacturing capabilities, quality certifications, delivery reliability, and technical support services. Established manufacturers with proven track records provide greater assurance of consistent quality and reliable delivery schedules that meet project timelines.

Material selection depends on specific application requirements, environmental conditions, and regulatory compliance needs. Carbon steel fittings offer excellent performance for standard applications, while stainless steel and alloy steel options provide enhanced performance for demanding environments.

Inventory management strategies should consider lead times, storage requirements, and project scheduling constraints. Large diameter fittings often require extended manufacturing periods, making early procurement planning essential for maintaining project schedules.

Total cost of ownership calculations should include purchase price, installation costs, maintenance requirements, and expected service life. Premium quality components often provide superior value despite higher initial costs due to reduced maintenance needs and extended service intervals.

Conclusion

Selecting the ideal large diameter steel pipe fittings for heavy-duty development requires cautious thought of quality, execution, and provider unwavering quality. The components highlighted in this investigation speak to demonstrated arrangements that convey prevalent execution over differing applications and working conditions. Territorial showcase varieties request providers with worldwide involvement and comprehensive certification portfolios. Victory depends on collaborating with established producers who understand the basic significance of quality, convey unwavering quality, and specialized back. Speculation in premium quality fittings gives long-term esteem through diminished upkeep costs, expanded benefit life, and upgraded security execution that ensures both ventures and notorieties.

FAQ

Q1: What pressure ratings are available for large diameter steel pipe fittings?

A: Large diameter steel pipe fittings are available in pressure ratings ranging from 150 PSI to 3000 PSI, depending on material grade, wall thickness, and manufacturing standards. Carbon steel fittings typically handle pressures up to 3000 PSI, while stainless steel options can accommodate similar ranges with enhanced corrosion resistance.

Q2: How do I determine the correct material grade for my application?

A: Material selection depends on operating temperature, pressure, corrosive environment, and regulatory requirements. Carbon steel grades like A234 WPB suit standard applications, while alloy steel grades (WP11, WP22) handle high-temperature conditions. Stainless steel grades (316L, 321) provide excellent corrosion resistance for chemical processing applications.

Q3: What certifications should I require from pipe fitting suppliers?

A: Essential certifications include ISO 9001 for quality management, ASME B16.9 for dimensional compliance, and material test certificates (MTCs) for chemical composition and mechanical properties. Regional certifications like CE marking for European markets or GOST-R for CIS countries may also be required, depending on project location.

Why Choose JS FITTINGS as Your Trusted Large Diameter Steel Pipe Fittings Supplier?

Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd (JS FITTINGS) stands as your reliable partner for premium large diameter steel pipe fittings that meet the most demanding construction requirements. Our four decades of manufacturing experience, combined with advanced production capabilities and comprehensive quality certifications, ensure your projects receive components that exceed expectations.

Our ISO 9001, CE, and GOST-R certifications demonstrate our commitment to international quality standards, while our four advanced production lines deliver consistent quality and reliable delivery schedules. We understand the critical importance of meeting project deadlines and maintaining safety standards that protect your reputation and bottom line.

Whether you're an EPC contractor managing complex industrial projects, a distributor serving local markets, or a government entity developing critical infrastructure, JS FITTINGS provides the technical expertise and manufacturing capabilities to support your success. Our extensive experience serving clients across the Middle East, South America, Europe, and Asia gives us unique insights into regional requirements and compliance standards.

Ready to discuss your large diameter steel pipe fitting requirements? Our technical team stands ready to provide detailed specifications, competitive pricing, and delivery schedules that align with your project needs. Contact us at admin@chinajsgj.com to discover how JS FITTINGS can contribute to your project success through superior quality and reliable service.