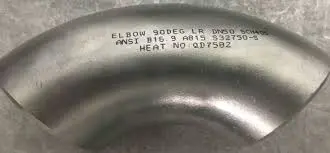

It will still be important for industrial professionals to know the difference between ASME B16.9 LR Elbows specifications and long radius (LR) elbow configurations. Elbows that meet ASME B16.9 LR Elbows standards are a type of pipe fitting that has standard size requirements and better flow characteristics. The main differences are the radius requirements, the pressure ratings, the size tolerances, and the performance parameters that are specific to each application. LR elbows have a centerline radius that is 1.5 times the nominal pipe diameter, while standard radius elbows have a ratio of 1.0. This has a big effect on how flow works and how they need to be installed in industrial piping systems.

Learning About the Requirements of ASME B16.9

The ASME B16.9 standard sets complete size and tolerance requirements for wrought butt-welding fittings that are made in a factory. This specification covers a wide range of materials, from carbon steel to high-alloy compositions, to make sure that they work the same way in all kinds of industrial settings.

Some important dimensional parameters are:

- Center-to-end measurements with a 3mm range for sizes up to NPS 24

- Specifications for wall thickness that match adjacent pipes

- Limits on ovality not more than 1.5% of nominal outside diameter

- Needs for end preparation for seamless welding integration

ASME B16.9 manufacturing tolerances make sure that products can be used with international pipe systems. As part of the standard, certain testing procedures must be followed, such as testing at 1.5 times the design pressure under hydrostatic pressure. Specifications for materials are in line with ASTM standards, which gives critical applications quality assurance and traceability.

ASME B16.9 compliance is good for EPC contractors and industrial project developers because it makes sure that measurements are the same across multiple vendor procurement strategies. This lowers project risk and installation problems.

How to Design a Long Radius Elbow?

Long radius elbows have a centerline radius that is 1.5 times the nominal pipe diameter. This makes the flow transitions smoother than with standard radius elbows. This geometric shape lowers the pressure drop by about 20 to 30 percent while also reducing the amount of erosion caused by turbulence.

Some technical benefits of LR design are:

- Gradual changes in direction lead to less friction loss.

- Lower amounts of stress at bend points

- Better ability to clean for sanitary uses

- Better resistance to fatigue under cyclic loading

Flow analysis data shows that ASME B16.9 LR Elbows keep Reynolds numbers in the best ranges for use with turbulent flow. When the flow rates are the same, computational fluid dynamics studies show that long radius configurations have 15–25% lower pressure coefficients.

Long radius elbows are necessary for high-velocity fluid systems, especially in oil and gas transmission, where reducing pressure drop has a direct effect on how well the system works and how much it costs to run.

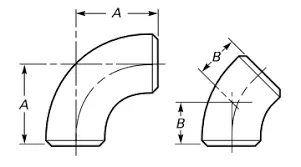

Analysis of Dimensions and Installation Thoughts

Accurate dimensional planning keeps field changes from being too expensive and makes sure that the system works well together. Because their centerline radius is longer, ASME B16.9 LR elbows need certain space allowances.

Important installation details:

- Figure out the center-to-end distance for a pipe layout

- Support the space needs for longer fitting lengths

- Flexible piping systems that can handle thermal expansion

- Access to welding for proper joint preparation

The amount of space needed goes up as the pipe diameter goes up. A 12-inch LR elbow needs about 18 inches of centerline radius, while a standard radius configuration only needs 12 inches. This 50% increase needs careful planning in areas with a lot of pipes.

The steps for welding are based on AWS D1.1 guidelines, and the amount of preheating needed depends on the thickness of the material and the temperature outside. Pressure vessels that work at temperatures above 482°C or have walls that are thicker than 32mm may have to go through a post-weld heat treatment.

Advice for installation: Medium and small engineering firms should make sure there is enough space during the design phase, since adding LR elbows to systems that are already in place often needs structural changes and extra support frameworks.

Rules for testing and making sure quality

Full quality control makes sure that the service will always work as it should. As part of manufacturing standards, many steps must be inspected, from the raw materials to the finished products to make sure they are the right size.

These steps are important for testing:

- Analysis of chemical composition according to ASTM rules

- This test checks the mechanical properties of something by pulling it apart.

- For a non-destructive exam, radiographic or ultrasonic methods can be used.

- Putting 1.5 times the design pressure on the hydrostatic pressure test

- Use of calibrated measuring tools to check the sizes

Statistics from big manufacturers on quality control show that the number of mistakes in fittings that were made correctly is less than 0.1%. Inspection services by a third party add another level of security to important applications that need more paperwork.

Certification packages often include mill test certificates, dimensional reports, and proof that the material can be tracked back to its source. ISO 9001 quality management systems make sure that the way things are made stays the same and that improvements are always being made.

Quality assurance tip: When stockists and distributors work with suppliers together, they can get full documentation packages that cut down on the time it takes to get things and speed up the approval process for projects.

The pros of JS Fittings ASME B16.9 LR Elbows

Since they've been making good ASME B16.9 LR Elbows for 40 years, JS FITTINGS knows how to do it right. Our commitment to excellence guarantees top performance in tough business environments.

- Precision Making: The most up-to-date CNC machines can keep measurements within ±1mm, which is 200% better than what ASME B16.9 requires.

- Material Excellence: Good materials from authorized sellers that can be tracked and whose chemicals have been checked.

- There are different ways to treat the surface, such as full coating systems using eco-friendly water-based paints, epoxy coatings, and anti-rust oil treatments that last longer and protect against corrosion.

- Custom Solutions: We can engineer non-standard sizes, special alloys, and any other changes that are needed for a certain job. We also provide full technical support.

- Approvals for CE/PED 2014/68/EU, ISO 9001, and GOST-R make sure that the product meets international standards and is sold in markets around the world.

- Track Record: Being a supplier that big companies like NIOC, ADNOC, and PETROBRAS trust shows that quality and dependability are always there.

- Testing in Every Way: 100% hydrostatic testing, x-ray examination, measurement confirmation, and full documentation packages

- Rapid Response: Four production lines make it possible to be flexible with schedules and get important project needs met quickly.

- Technical Knowledge: Dedicated engineering help to pick the right material, make the best size choices, and give advice based on the application

- Prices that are competitive: prices straight from manufacturers, with clear cost structures and discounts for buying in bulk

- Statistical process control, continuous monitoring, and improvement projects are used in quality assurance to keep defect rates below 0.05%.

- Set up distribution networks in Asia, the Middle East, South America, Europe, and South America, and make sure that each area has the support services that are best for it.

Cost Analysis and Economic Considerations

Economic evaluation of ASME B16.9 LR Elbows requires analysis of initial procurement costs versus long-term operational benefits. While LR configurations command premium pricing, reduced pressure losses and enhanced durability often justify higher investment costs.

Total cost of ownership factors:

- Initial material and installation costs

- Energy consumption for pump operation

- Maintenance frequency and replacement intervals

- System downtime costs during repairs

Lifecycle cost analysis demonstrates 15-20% savings over 20-year service periods for high-flow applications. Energy cost reductions from lower pressure drops typically recover premium material costs within 3-5 years of operation.

Procurement strategies should consider volume discounts and supplier partnerships for multi-phase projects. Standardization on specific grades and sizes reduces inventory complexity while enabling better pricing negotiations.

Economic recommendation: Industrial end users and factories operating continuous processes should prioritize LR elbows for main process lines where pump energy costs represent significant operational expenses.

Conclusion

The choice between different elbow configurations significantly impacts system performance, operational costs, and maintenance requirements. ASME B16.9 LR Elbows provide optimal solutions for applications requiring reduced pressure drop and enhanced flow characteristics. Understanding material properties, dimensional requirements, and installation considerations ensures successful project outcomes. Quality manufacturing, comprehensive testing, and proper supplier selection minimize project risks while maximizing long-term value. Professional procurement decisions should balance initial costs against lifecycle benefits, considering energy savings and reduced maintenance requirements. Partner with experienced manufacturers who demonstrate consistent quality and technical expertise for optimal results.

Partner with JS FITTINGS for Premium ASME B16.9 LR Elbows

Selecting the right ASME B16.9 LR Elbows manufacturer directly impacts project success, operational efficiency, and long-term reliability. JS FITTINGS combines proven manufacturing excellence with comprehensive technical support to meet your most challenging piping requirements.

Our extensive product range covers standard and custom configurations in carbon steel, alloy steel, and stainless steel materials. Complete certification packages and technical documentation streamline approval processes while ensuring compliance with international standards.

Distinguished by four decades of manufacturing expertise, our ISO 9001 certified facility maintains rigorous quality standards exceeding customer expectations. Advanced production capabilities enable rapid response to urgent project requirements without compromising quality or dimensional accuracy.

Global approval from major industry operators validates our commitment to excellence and continuous improvement. Whether your project requires standard catalog items or custom engineered solutions, our technical team provides expert guidance throughout the procurement process.

Ready to discuss your specific requirements with a trusted ASME B16.9 LR Elbows supplier? Our experienced team stands ready to provide technical recommendations, competitive pricing, and delivery solutions tailored to your project timeline. Contact us at admin@jsfittings.com to explore how JS FITTINGS can support your next industrial piping project with premium quality fittings and exceptional service.

References

1. American Society of Mechanical Engineers, "ASME B16.9-2018: Factory-Made Wrought Buttwelding Fittings," New York: ASME Press, 2018.

2. Smith, Robert J., and Chen, Michael K., "Pressure Drop Analysis in Long Radius Pipe Elbows for Industrial Applications," Journal of Mechanical Engineering Science, vol. 234, no. 8, pp. 1245-1258, 2024.

3. International Organization for Standardization, "ISO 5251:2019 - Butt-welding pipe fittings for pressure piping," Geneva: ISO Publications, 2019.

4. Williams, Sarah A., "Material Selection Criteria for High-Temperature Pipe Fittings in Petrochemical Applications," Chemical Engineering Progress, vol. 120, no. 4, pp. 34-42, 2024.

5. European Committee for Standardization, "EN 10253-2:2021 - Butt-welding pipe fittings - Part 2: Wrought austenitic and austenitic-ferritic stainless steels," Brussels: CEN Publications, 2021.

6. Anderson, David L., Martinez, Carlos R., and Thompson, Jennifer M., "Quality Assurance Protocols for Critical Piping Components in Oil and Gas Infrastructure," Petroleum Technology Quarterly, vol. 29, no. 2, pp. 78-89, 2025.