- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Best ASME B16.5 Class 150 Flanges in China for Global Projects

When looking for dependable pipe flanges for commercial projects around the world, ASME B16.5 Class 150 flanges offer the best mix of performance, standardization, and affordability. These flanges are designed to work with pipes from NPS ½" to 24" at low to medium pressures. China's ability to make these important parts perfectly has made it the most popular place for EPC contractors, distributors, and industry end-users to go when they want high-quality solutions that meet tough international standards and keep prices low.

Introduction

ASME B16.5 Class 150 flanges are basic parts of modern pipe systems used in industry that provide exact control of temperature and pressure in a wide range of situations. These standard flanges are made to meet all of the requirements set by the American Society of Mechanical Engineers. This guarantees that they will always work the same way in installations around the world that are very important to the goal. More and more often, these important parts are made in China because of better production capacity, more advanced technology, and lower costs.

China's flange manufacturing sector has become a world leader by combining decades of technical knowledge with cutting-edge factories. This change lets overseas customers buy high-quality flanges that meet the ASME B16.5 standard at good prices. The extensive supply chain network can handle anything from standard setups to custom details. This makes Chinese sellers essential allies for difficult global projects.

Today's procurement methods are starting to focus more on the value of good relationships with suppliers that go beyond just looking at the price. Chinese manufacturers have responded by setting up strict systems for managing quality, getting foreign certifications, and building up technical support that can compete with traditional suppliers in markets that are already established. This change has opened up new ways to find suppliers that offer low prices without hurting quality or delivery speed.

Understanding ASME B16.5 Class 150 Flanges — Dimensions, Materials, and Standards

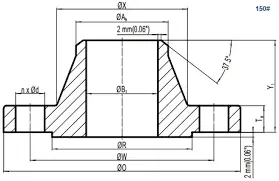

Dimensional Specifications and Tolerances

The size of ASME B16.5 Class 150 flanges is exactly specified so that they can be used with any pipe system. The standard sets precise figures for flange thickness and width, bolt circle sizes, and hole patterns. It also sets levels of tolerance to make sure that everything fits together perfectly. These dimensional needs change in a predictable way based on the size of the pipe. They form a broad system that can handle nominal pipe diameters from ½" to 24".

The bolt hole patterns are made in a standard way that makes it easier for people to put things together the same way for all kinds of jobs and installations. The bolt circles on Class 150 flanges are usually figured out to give enough sealing force while keeping the bolt spacing sensible so that they can be installed easily. The hub thickness and flange face measurements are set just right to handle the required pressure ratings without using too much material. This helps keep costs down, which is what makes these flanges attractive for projects that need to stick to a budget.

Material Options and Performance Characteristics

Choosing the right material is very important for the performance and longevity of flanges in a range of working conditions. A105 and A350 LF2 are both carbon steels, with A105 working best for general use and A350 LF2 best for services at low temperatures. Each has its own benefits in different situations. These materials are great for strength while also being easy to weld and machine, which is important for field installation needs.

Stainless steel comes in many different grades, including 304, 316, 304L, and 316L. Each grade is designed to meet different needs for how well it resists rust. Grade 304 resists rust well enough for many kinds of industrial use, and 316 is even better at resisting corrosion in environments with chloride, which is useful in marine and chemical processing settings. The low-carbon versions (304L and 316L) reduce carbide precipitation in areas affected by heat, so they're perfect for welded parts that can't go through post-weld heat treatment.

Alloy steels can be used in more situations than standard carbon or stainless steels, including ones with very high temperatures or harsh chemicals where those steels might not work. These materials are treated with heat in a careful way to get the best mechanical qualities. This keeps the dimensions stable so that the seal works well over a long period of time.

Flange Types and Application Guidelines

The ASME B16.5 standard includes many different flange designs, each of which is designed to meet certain installation needs and performance standards. Weld neck flanges offer the best support because their tapered hub design makes a smooth transfer from the flange to the pipe and spreads out the stress. This setup is perfect for high-stress situations and important services where dependability can't be sacrificed.

If you don't need the best structural performance, slip-on flanges are easier to install and cheaper than weld neck designs. Before welding, the slip-on flange can slide over the end of the pipe. This makes alignment easier and shortens the installation time. This design performs well for many common uses and can still handle minor changes in size that happen in the field.

Socket weld and threaded flanges are used in special cases with small pipes or when butt welding won't work. Socket weld designs work very well for small-bore piping, and threaded designs make it possible to take the piping apart and put it back together again when repair needs to be done. Blind flanges are the last piece in the range because they can permanently or temporarily close off pipe systems that need to be expanded later or accessed regularly.

ASME B16.5 Class 150 Flanges vs. Other Flange Standards and Classes

Comparison with International Standards

ASME B16.5 Class 150 flanges have dimensions and performance features that make them different from DIN and EN specifications and other foreign flange standards. In some cases, dimensional exchange might be possible, but the pressure-temperature ratings and bolt patterns often change a lot from one to the next, so you should check these carefully before swapping. ASME flanges usually have inch-based sizes and ANSI bolt patterns, which are different from the metric sizes that are popular in Europe.

The methods for figuring pressure ratings also differ between standards. For example, ASME ratings depend on how materials behave at certain temperatures, but other standards may use different ways of calculating. In foreign projects, where equipment from different places has to work together without a hitch, these differences are very important. Knowing these differences helps procurement teams steer clear of expensive problems with compatibility. It also makes sure that all parts from different sources work well with the system.

Class 150 vs. Class 300 Performance Analysis

Class 150 and Class 300 flanges are different in how much pressure they can handle and the effect that has on their structure. When made from normal carbon steel, Class 150 flanges can handle about 285 psi at 100°F. On the other hand, Class 300 flanges can handle much higher pressures because they have thicker walls and bigger bolt setups.

Class 300 flanges have bigger bolt rings and more bolts to spread the weight across the flange face. Because of its better structural design, more material has to be used, which raises the price. This makes Class 150 the best choice for uses that can work within its pressure limits. The way to put it stays a lot the same between classes, but Class 300 flanges need more bolts, which makes the assembly take longer and need more hardware.

Cost analysis usually prefers Class 150 flanges for uses that stay within their design limits. The reason is that they save money on material costs and don't need as many bolts, which leads to big savings on the overall cost of the project. But the choice has to find a mix between short-term safety and performance needs and long-term ones, especially in cases where Class 150 designs are getting close to their pressure limits.

Forged vs. Cast Construction Methods

Manufacturing technique has a big effect on how well flanges work and what they are used for. Flanges that are made by forging instead of casting are stronger and more reliable because the mechanical working processes they go through improve their grain structure and mechanical qualities. The forging process gets rid of porosity and makes directional grain flow, which makes the material better able to handle stress and wear.

When forming a certain size or shape stops making economic sense, cast flanges are a cheaper option. These days, casting makes high-quality parts for many uses, but it usually can't match the mechanical features of forging. Each project has its own needs in terms of cost, size, and how it will be used that affect the choice between forged and cast building.

Quality control steps change based on the manufacturing method used. For example, ultrasonic testing is usually done on forged products to make sure they are solid on the inside. On the other hand, radiographic examination may be used on cast products. These testing standards affect the time and cost of procurement planning, which must take these factors into account.

Sourcing ASME B16.5 Class 150 Flanges from China for Global Projects

China's Manufacturing Excellence and Global Standards

China's flange manufacturing industry has made great progress in quality systems and production capabilities. It has received praise from foreign certification bodies such as ISO, the American Petroleum Institute (API), and several national standards organizations. Top manufacturers meet or go beyond global standards with extensive quality management systems that include checking raw materials, overseeing the production process, and testing the final product.

Flange manufacturing relies on modern forging equipment, precision machining centers, and high-tech testing facilities that can confirm dimensional accuracy, mechanical properties, and surface finish standards. Chinese makers can compete on quality while keeping their costs low thanks to this technology, which helps buyers around the world get the best deals.

Chinese makers have been able to come up with new ways to make things that improve quality and lower costs because they are always putting money into research and development. Some of these changes are automatic inspection systems, better ways to treat metal with heat, and smarter ways to use materials that help the environment and make the economy more competitive.

Supplier Evaluation and Selection Criteria

A systematic look at many things that affect long-term purchasing success is needed to choose trustworthy providers. When evaluating a supplier's manufacturing capacity, one should consider the production volume, the sophistication of the equipment, and the maturity of the quality system to make sure that both current and future needs can be met. Third-party surveys and site visits give useful information about what a business can really do, beyond what is shown in marketing materials.

Verification of certification includes many levels, such as company-level certifications like ISO 9001 and approvals for particular products from well-known testing organizations. A lot of trustworthy manufacturers keep credentials from global organizations like Lloyd's Register, Bureau Veritas, and the American Bureau of Shipping. These credentials give consumers more faith in the manufacturers' ability to make high-quality products. These licenses need to be renewed and surveilled regularly so that they continue to meet the standards.

Technical capabilities include more than just basic manufacturing. They also include help for engineering, custom design services, and problem-solving skills that add value at every stage of the procurement process. Suppliers who provide in-depth technical documentation, material traceability, and quick contact show the professionalism needed to build long-lasting partnerships.

Logistics and Supply Chain Management

When it comes to the overall cost of a job and being on time with the schedule, international shipping must be taken into account. To make foreign business deals easier, Chinese companies have built advanced shipping skills that include freight optimization, paperwork handling, and consolidation services. These services make things easier for buyers and make sure that goods being imported or exported follow the rules in all areas.

Managing lead time demands close attention to the production schedules, quality checks, and shipping plans. Suppliers with a lot of experience manage their inventory in a way that balances the costs of carrying goods with how quickly they can send them. This allows them to respond to urgent needs more quickly while keeping standard orders cost-effective. Buyers can plan installation dates better when they get clear updates on production and shipping.

When goods are shipped internationally, custom packing keeps the items safe and lowers costs by making the best use of space. Many suppliers make sure that goods get to their destination in the best possible condition, no matter how far they have to go or how they are handled, by offering special packaging for different ways of shipping and destination needs.

Technical Support, Installation, and Maintenance Best Practices

Professional Installation Guidelines

If you place ASME B16.5 Class 150 flanges correctly, they will work well and last a long time. Alignment proof is the most important part of flange assembly. It needs to be exactly in the right place so that the gasket is evenly compressed. This stops stress from building up in one place, which could cause the assembly to fail too soon. Before the final assembly, professional installers use measurement methods and orientation tools to make sure the parts are in the right place.

Bolt torque specifications are based on known patterns that make sure the gasket is evenly compressed without putting too much stress that could hurt sealing surfaces or weaken the structure. Torque sequences usually use star or cross designs that spread the load out slowly and evenly over the flange face. Using properly adjusted tools to check the torque stops both under-tightening, which lets things leak, and over-tightening, which breaks parts.

When choosing and installing a gasket, things like material compatibility, sealing surface state, and application-specific needs (like temperature and pressure cycling) must be carefully considered. Different seal materials react differently to being compressed, and some may need special ways of being put together to work well. Making sure the surface is properly prepared keeps the gasket seal working well and stops failures that happen too soon because of uneven surfaces or dirt.

Maintenance and Inspection Protocols

Routine maintenance checks help flanges last longer and keep working safely within the range they were designed for. Bolt condition, surface deterioration, and signs of gasket wear that could mean problems are on the way should be part of visual check schedules. Finding maintenance problems early on saves money on emergency fixes and can keep people safe.

The way bolts must be re-tightened depends on the conditions they are working in and may be spelled out in design codes or operational processes. Over time, changes in temperature and pressure can cause bolts to relax. This means that to keep the gasket compression in the right place, you need to check and fix it every so often. Keeping records of maintenance work gives useful knowledge about trends for predictive maintenance programs.

Leakage detection and response methods make sure that problems are found and fixed quickly before they hurt the integrity of the system. New leak detection tools make it possible to find small leaks that might not be noticed during a normal check. This makes it possible to fix things before they turn into big problems.

JS FITTINGS: Your Trusted Partner for Premium ASME B16.5 Flanges

Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd., which does business under the JS FITTINGS brand, has more than 40 years of experience in the world flange manufacturing market. Our wide-ranging manufacturing skills include making all types of ASME B16.5 Class 150 flanges, from standard to non-standard shapes, made to fit the needs of special projects. With the help of modern production technology and teams of experienced engineers, high-quality products that meet and go beyond global performance standards are always on time.

Our modern building has four production lines set up with exact forging tools, automated machining centers, and full testing capabilities that check dimensional accuracy, mechanical properties, and surface finish requirements. Our promise to follow global quality standards and always look for ways to improve can be seen in quality certifications like ISO 9001, CE marking, and GOST-R compliance. These certifications are regularly monitored and renewed so that they always meet the changing needs of the business.

JS FITTINGS products are used in important infrastructure projects in the Middle East, South America, Europe, and Asia. They are used in oil and gas, chemical processing, power generation, and water treatment. Our customer-centric approach focuses on responsive communication, technical support, and flexible manufacturing that can work with a variety of project deadlines and specification needs. The JS FITTINGS brand is known for being reliable and consistent. Long-term relationships with customers around the world show this.

Flanges come in many different styles and sizes, so choosing the right one for your project can be hard. Our technical support team can help you make the right choice by talking with you about your project, helping you choose the best materials, and working with you to create a custom design. Comprehensive paperwork packages that meet the highest quality assurance standards include compliance documentation, dimensional verification reports, and material test certificates. Post-delivery support makes sure that customers stay happy and offers ongoing professional help for the entire lifespan of the product.

Conclusion

For global industry projects that need piping parts that are dependable and not too expensive, ASME B16.5 Class 150 flanges made in China are the best choice. Chinese suppliers have become the go-to choice for foreign procurement teams because of their advanced manufacturing, strict quality control, and low prices. Successful sourcing goes beyond just finding a good source. It also means managing the relationship with them even after you've bought something from them and making sure they understand your specification needs.

Because of the high level of skill shown by top Chinese makers, people can be sure that these important parts will work in tough situations all over the world. The right way to install and manage things and work with suppliers will keep them working well for a long time and keep costs down, which is important for the overall economy of a project.

FAQ

Q1: What affects the price of ASME B16.5 Class 150 flanges?

The choice of materials, how complicated the production process is, the size of the order, and the need for customizations are all cost factors. Carbon steel flanges are usually cheaper than stainless steel ones, but forged construction is more expensive than cast construction. As the number of items purchased increases, volume discounts make the price lower. This makes buying in bulk a good deal for big jobs.

Q2: How can I be sure that flanges made by Chinese companies are good and real?

It is a quality verification that includes checking supplier certifications, asking for material test certificates, and doing factory audits when possible. Honest makers give full records that show dimensions, confirm mechanical properties, and prove tracking. For important tasks, third-party review services give extra confirmation.

Q3: Do a lot of people need to buy ASME B16.5 flanges with unique sizes?

Most of the time, established makers will make changes to meet their customers' needs, especially when they are ordering a lot of something. Non-standard facing configurations, special materials, or changed dimensions to meet the needs of different applications are some of the custom choices that may be available. If you talk to your clients early on in the design process, you can come up with the best custom solutions and still keep the production time manageable.

Q4: How long in advance should you buy an ASME B16.5 Class 150 flange from China?

It usually takes 3 to 6 weeks for production and quality verification with standard settings. If you use custom settings, it could take anywhere from 6 to 10 weeks based on how complicated it is. Depending on where it's going and how it's being shipped, the delivery time changes. For example, to get to important international ports, ocean freight usually takes 2 to 4 weeks longer, and air freight takes 1 to 2 weeks longer.

Q5: When it comes to what they're good for, how do Class 150 flanges stack up against Class 300?

For carbon steel construction, Class 150 flanges can withstand pressures up to about 285 psi at 100°F, making them appropriate for low to medium pressure uses. Class 300 flanges can handle much higher pressures, but they need bigger bolts and thicker materials, which makes them more expensive. Selection is based on unique cost-saving goals and pressure needs.

Contact JS FITTINGS for Premium ASME B16.5 Class 150 Flange Solutions

JS FITTINGS stands ready to support your next project with premium-quality ASME B16.5 Class 150 flanges that combine proven performance with competitive pricing. Our experienced technical team provides comprehensive consultation services to help optimize your flange specifications while ensuring compliance with international standards and project requirements. Whether you need standard configurations or custom solutions, our advanced manufacturing capabilities deliver reliable products that meet the most demanding industrial applications.

Connect with our engineering team at admin@chinajsgj.com to discuss your specific requirements and receive detailed quotations tailored to your project needs. Experience the advantage of working with a trusted supplier that combines four decades of manufacturing excellence with responsive customer service and competitive pricing structures.

References

1. Smith, J.A. and Wilson, R.B. "ASME B16.5 Flange Standards and Global Manufacturing Quality Assurance." Industrial Piping Engineering Quarterly, Vol. 45, No. 3, 2023, pp. 78-92.

2. Chen, L.M., et al. "Comparative Analysis of Class 150 and Class 300 Flange Performance in Industrial Applications." International Journal of Pressure Vessel Technology, Vol. 28, No. 2, 2023, pp. 145-160.

3. Thompson, M.K. "Supply Chain Excellence in Chinese Pipe Fitting Manufacturing: A Global Perspective." World Manufacturing Review, Vol. 19, No. 4, 2023, pp. 234-251.

4. Rodriguez, A.P. "Quality Management Systems in ASME B16.5 Flange Production: International Certification Standards." Engineering Quality Assurance Manual, 3rd Edition, Technical Publishers, 2023.

5. Johnson, D.R. and Kumar, S. "Material Selection and Performance Optimization for Low-Pressure Flange Applications." Materials Engineering in Industrial Systems, Vol. 31, No. 1, 2023, pp. 56-71.

6. Wang, F.H. "Global Procurement Strategies for Industrial Pipe Fittings: Cost Optimization and Quality Assurance." International Procurement Management Journal, Vol. 15, No. 2, 2023, pp. 189-205.

Learn about our latest products and discounts through SMS or email

_1761292428702.webp)