Finding the best buttweld fittings requires understanding fabric guidelines, dependable sourcing, and comprehensive OEM choices. Quality buttweld fittings serve as basic pipe joints in mechanical applications, where consistent associations guarantee ideal execution and security. Driving producers like JS FITTINGS give carbon steel, stainless steel, and combination steel choices that meet worldwide benchmarks, including ASME B16.9 and ASTM details. With appropriate fabric choice, weight rating compliance, and erosion resistance properties, these mechanical fittings provide remarkable unwavering quality over assorted pipeline frameworks worldwide.

Understanding OEM/ODM Excellence in Pipe Fittings Manufacturing

Original Equipment Manufacturing (OEM) and Original Design Manufacturing (ODM) speak to two particular approaches to custom pipe fittings generation. OEM includes fabricating items according to client determinations, whereas ODM includes total plan improvement near fabricating capabilities.

The worldwide pipe fittings showcase requests accuracy, design, and rigid quality control. Cutting-edge mechanical ventures require fittings that withstand extraordinary temperatures, destructive situations, and high-pressure applications. Custom arrangements ended up fundamental when standard items cannot meet particular extend requirements.

Deep customization thing altogether in today's competitive scene. EPC temporary workers overseeing large-scale ventures require fittings made to correct details. Government framework improvements require compliance with neighborhood controls and worldwide benchmarks. Wholesalers look for solid accomplices who can provide reliable quality while keeping up competitive pricing structures.

Our OEM/ODM Strengths in Buttweld Fittings Manufacturing

JS FITTINGS brings over four decades of fabricating ability to each extend. Our broad encounter ranges from numerous businesses, from petrochemical plants to control era offices. We get it, the one-of-a-kind challenges each division presents, and create arrangements accordingly.

Our fabricating capabilities incorporate four progressed generation lines equipped with modern production, machining, and warm treatment equipment. These offices empower us to deliver consistent and welded fittings in different sizes, from standard attachment weld associations to large-diameter reducers and tees.

Research and advancement remain central to our operations. Our building group persistently assesses unused materials, fabricating forms, and plans advancements for buttweld fittings. This commitment guarantees our items meet advancing industry requests while keeping up cost-effectiveness.

Quality control systems at JS FITTINGS exceed industry standards. ISO 9001 certification demonstrates our commitment to consistent quality management. CE marking ensures European compliance, while GOST-R certification opens markets across CIS countries. Each buttweld fitting undergoes rigorous testing, including dimensional verification, material analysis, and pressure testing.

Supply chain optimization enables us to source premium raw materials at competitive prices. Long-term partnerships with steel suppliers ensure consistent material quality and availability. Strategic inventory management minimizes lead times while maintaining cost efficiency.

Comprehensive Customization Options for Industrial Applications

Physical design customization encompasses dimensional modifications, wall thickness variations, and specialized end preparations. We manufacture elbows in angles beyond standard 45° and 90° configurations. Tee designs can incorporate unequal branch connections for specific applications. Reducer profiles can be modified to accommodate unique flow requirements.

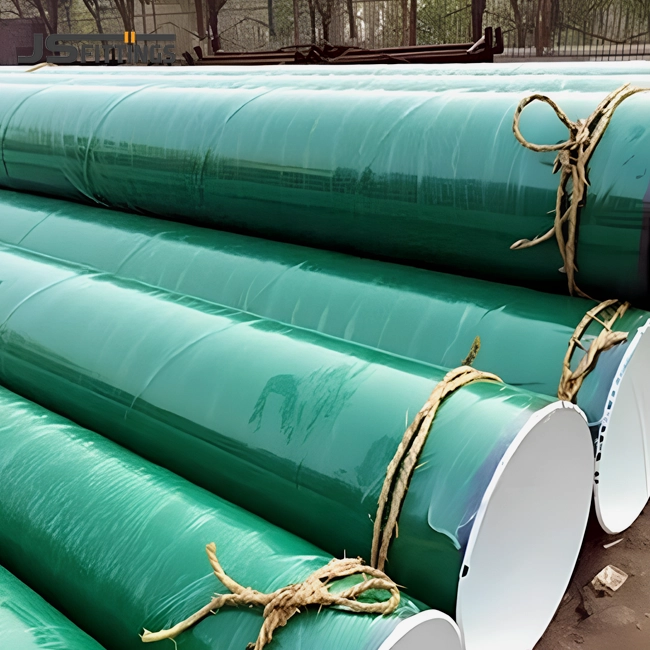

Functional features expand beyond basic connectivity. Enhanced corrosion resistance through specialized coatings protects fittings in harsh environments. Improved flow characteristics reduce pressure losses in critical applications. Reinforced designs handle extreme pressure ratings while maintaining structural integrity.

Technology integration incorporates progressed manufacturing procedures like precision machining and controlled warm treatment. Computer-aided plan guarantees dimensional exactness over generation runs. Robotized testing frameworks confirm execution characteristics some time recently shipment.

Branding customization makes a difference; wholesalers set up advertising nearness. Custom checking incorporates company logos, portion numbers, and traceability codes. Bundling arrangements ensure items during transportation while advancing brand recognition.

Compliance customization addresses territorial directions and industry measures. ASME B16.9 compliance guarantees North American advertising acknowledgment. EN guidelines meet European prerequisites. Nearby certifications encourage showcase passage in creating regions.

The ODM Advantage in Developing Next-Generation Pipe Joints

Our ODM capabilities enable collaborative development of innovative buttweld fittings. Client partnerships begin with concept evaluation and extend through prototype development, testing, and full-scale production.

Material science expertise helps select optimal alloys for specific applications. Stainless steel grades like 316L provide superior corrosion resistance in marine environments. Carbon steel variants offer cost-effective solutions for standard applications. Specialized alloys address extreme temperature and pressure conditions.

Design optimization decreases fabric utilization while improving execution. Progressed modeling program predicts stretch distributions and recognizes potential disappointment focuses. Model testing approves plan concepts, sometimes recently generating tooling investment.

Market examination recognizes rising patterns and application requirements. Our group screens industry advancements, administrative changes, and mechanical progress. These insights guide buttweld fittings item improvement choices and advertising situating strategies.

Our Streamlined Customization Process

Project initiation begins with detailed requirement analysis. Our technical team reviews specifications, application conditions, and performance expectations. Site visits and virtual consultations ensure a complete understanding of project needs.

Design improvement joins client input at each organize. Beginning concepts experience survey and refinement based on input. Computer-aided planning apparatuses empower fast emphasis and visualization of proposed solutions.

Prototype generation permits execution approval some sometimes recently full-scale manufacturing. Test fittings experience a comprehensive assessment, including weight testing, fabric examination, and dimensional confirmation. Client endorsement affirms plan acknowledgment and generation readiness.

Production planning optimizes fabrication effectiveness while keeping up quality benchmarks. Fabric acquisition guarantees accessibility of certified crude materials. Generation planning obliges extend timelines and conveyance requirements.

Quality assurance continues throughout manufacturing. In-process inspections verify dimensional accuracy and material properties. Final testing confirms compliance with specifications and industry standards.

Benefits to Your Business Success

Cost optimization through efficient manufacturing processes reduces overall project expenses. Our economies of scale enable competitive pricing without compromising quality. Value engineering identifies opportunities to enhance performance while controlling costs.

Risk mitigation through proven manufacturing capabilities ensures project success. Established quality systems minimize defect rates and delivery delays. Comprehensive testing validates product performance before shipment.

Market differentiation through custom solutions creates competitive advantages. Unique designs protect intellectual property and market position. Enhanced performance characteristics justify premium pricing structures.

Supply chain reliability supports business continuity and growth. Consistent delivery performance enables accurate project planning. Flexible production capacity accommodates varying buttweld fittings demand patterns.

Technical support extends beyond product delivery. Our engineering team provides installation guidance and troubleshooting assistance. Ongoing collaboration ensures optimal product performance throughout service life.

Conclusion

Selecting the right buttweld fittings producer requires cautious assessment of fabric benchmarks, sourcing capabilities, and OEM alternatives. JS FITTINGS combines four decades of fabricating ability with advanced generation offices to provide predominant pipe joints for demanding applications. Our comprehensive customization capabilities, thorough quality control systems, and worldwide advertise nearness position us as your perfect manufacturing accomplice. The combination of competitive estimating, dependable conveyance, and specialized brilliance guarantees success over differing mechanical sectors.

FAQ

Q1: What material standards does JS FITTINGS follow for buttweld fittings production?

A: We manufacture buttweld fittings according to ASME B16.9, ASTM A234, and EN standards. Our materials include carbon steel grades like ASTM A234 WPB, stainless steel varieties including 304L and 316L, and specialized alloys for extreme applications. All materials come with certified mill test certificates ensuring traceability and compliance.

Q2: How does your OEM process ensure quality control throughout production?

A: Our quality control system includes incoming material inspection, in-process monitoring, and final product testing. Each fitting undergoes dimensional verification, hardness testing, and pressure testing where applicable. ISO 9001 certification ensures consistent quality management processes across all production activities.

Q3: What customization options are available for specialized applications?

A: We offer comprehensive customization, including non-standard dimensions, special materials, unique end preparations, and enhanced corrosion protection. Our engineering team can modify wall thickness, pressure ratings, and dimensional specifications to meet specific project requirements while maintaining structural integrity and performance standards.

Partner with JS FITTINGS for Your Buttweld Fittings Manufacturing Needs

JS FITTINGS stands ready to transform your pipe fitting requirements into reality. Our comprehensive OEM and ODM capabilities serve as your complete buttweld fittings supplier solution. Whether you need standard products or custom-engineered solutions, our four decades of manufacturing excellence deliver results that exceed expectations.

Our global reach extends across Middle East markets, South American regions, European territories, and Asian countries. Local market knowledge combined with international manufacturing standards ensures products meet regional requirements while maintaining global quality benchmarks.

Competitive pricing structures help maintain healthy profit margins across your product portfolio. Our efficient manufacturing processes translate into cost savings that benefit your bottom line. Volume production capabilities support both large-scale projects and ongoing supply agreements.

Ready to discuss your next project? Our technical team awaits your specifications and application requirements. Contact us at admin@jsfittings.com to begin developing your custom buttweld fittings solution. Together, we can engineer success for your industrial applications.

References

1. American Society of Mechanical Engineers. "ASME B16.9-2018: Factory-Made Wrought Buttwelding Fittings." ASME International, 2018.

2. ASTM International. "ASTM A234/A234M-20: Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service." ASTM International, 2020.

3. Nayyar, Mohinder L. "Piping Handbook." 8th Edition, McGraw-Hill Education, 2019.

4. European Committee for Standardization. "EN 10253-2:2020: Butt-welding pipe fittings." CEN European Standards, 2020.

5. Singh, Keval P. "Pipeline Engineering: Design, Installation and Maintenance." Petroleum Engineering Handbook, Society of Petroleum Engineers, 2017.

6. International Organization for Standardization. "ISO 9001:2015 Quality Management Systems - Requirements." ISO Publications, 2015.