- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

China Carbon Steel ERW Pipe Factory: Powering Southeast Asia’s Infrastructure

China carbon steel ERW pipe factory have evolved significantly over the last decade, establishing the region as a top supplier to markets in Southeast Asia. These factories utilize advanced High-Frequency Electric Resistance Welded (HFIW/ERW) technology to manufacture superior carbon steel pipes that are cost-effective, compliant with global standards, and highly durable.

With decades of experience and strict quality control, Chinese ERW pipe manufacturers have built strong relationships with contractors, distributors, and industrial end-users across Indonesia, Vietnam, Thailand, Malaysia, and the Philippines. This ensures dependable supply chains for critical infrastructure projects throughout the ASEAN region.

Understanding China Carbon Steel ERW Pipes: Manufacturing and Quality Standards

Advanced Manufacturing Processes and Welding Technology

Chinese carbon steel ERW pipes are produced using advanced automated lines that ensure consistent physical accuracy. The ERW process utilizes electrical resistance to heat steel strips to a welding temperature, creating a longitudinal seam without the need for filler metals. This manufacturing method grants the pipes excellent mechanical properties and uniform wall thickness, making them ideal for demanding industrial applications.

Modern Chinese factories employ precision forming mills and online heat treatment (Normalizing) to relieve stress, making the pipes stronger and more corrosion-resistant.

Quality control is rigorous. Real-time tracking of welding parameters, dimensional checks, and Non-Destructive Testing (NDT) methods—such as Ultrasonic and Hydrostatic testing—are standard procedures. These thorough checks ensure that each pipe meets the performance requirements of Southeast Asian construction and energy sectors.

International Standards Compliance and Certifications

Leading China carbon steel ERW pipe factories strictly adhere to international standards, including API 5L, ASTM A53, ASTM A252, EN 10219, and BS 1387. This multi-standard compliance allows manufacturers to meet diverse market needs, from Oil & Gas transmission to Structural Piling.

Surface treatments are customizable for the tropical Southeast Asian climate, including Varnish coating, 3PE (Three-Layer Polyethylene), FBE (Fusion Bonded Epoxy), and Hot Dip Galvanizing. These coatings significantly enhance corrosion resistance and extend service life.

Certification portfolios typically include ISO 9001, CE/PED 2014/68/EU, and approvals from major entities like ADNOC, ensuring reliability for critical projects.

Comparing China Carbon Steel ERW Pipe Factories: Making an Informed Supplier Choice

Essential Evaluation Criteria for Supplier Selection

Choosing the right factory requires evaluating production capacity and quality management. Top-tier manufacturers usually run multiple production lines with annual capacities ranging from 50,000 to 200,000 tons. This ensures they can handle bulk orders for mega-projects while maintaining delivery schedules.

Buyers should verify Mill Test Certificates (MTC) according to EN 10204 3.1. A manufacturer's dedication to transparency is visible in their willingness to provide detailed technical documents, dimensional inspection reports, and third-party inspection (TPI) access.

Performance Comparison: ERW Versus Seamless Alternatives

ERW pipes are significantly more cost-effective than Seamless (SMLS) pipes—often 15% to 30% cheaper. This is a major advantage for construction projects in Southeast Asia where budget control is key.

ERW Pipes: Best for Low/Medium pressure lines, Structural supports, Piling, and Water transmission. They offer superior wall thickness uniformity.

Seamless Pipes: Best for High-pressure and High-temperature environments.

For most general industrial and infrastructure needs in the Southeast Asian market, ERW pipes provide the best balance of performance and price.

Procurement Insights: How to Source Carbon Steel ERW Pipes from China Efficiently

Commercial Terms and Order Requirements

Most established factories set Minimum Order Quantities (MOQ) between 10 and 25 tons per size to maintain production efficiency. However, mixed-container orders are often available for distributors.

Pricing depends on steel grade, wall thickness, and surface treatment. Volume discounts usually kick in for orders exceeding 100 tons. Payment terms typically follow international standards (T/T or L/C), ensuring security for both parties.

Logistics and Delivery to Southeast Asia

Shipping from major Chinese ports (Tianjin, Shanghai, Qingdao) to key Southeast Asian hubs (Jakarta, Port Klang, Ho Chi Minh City, Manila, Bangkok) is fast, typically taking 10 to 20 days.

Factories can optimize container loading to lower shipping costs. For example, "nesting" smaller pipes inside larger pipes is a common strategy to maximize volume. Customization is also available, such as Fixed Lengths (e.g., 5.8m or 11.8m) to fit container sizes perfectly, or specialized beveled ends for easy on-site welding.

Applications and Benefits of Carbon Steel ERW Pipes for Southeast Asian Industries

Key Industrial Applications

Construction & Piling: Structural columns, scaffolding, and foundation piles.

Water & Sewage: Large diameter water transmission lines with anti-corrosion coatings.

Oil & Gas: Low-to-medium pressure pipelines for transport and distribution.

Economic and Performance Advantages

The primary advantage of sourcing from a China carbon steel ERW pipe factory is the Price-Performance Ratio. The controlled manufacturing process ensures dimensional uniformity, making installation quicker and reducing on-site welding time.

Your Trusted Partner in China Carbon Steel ERW Pipes

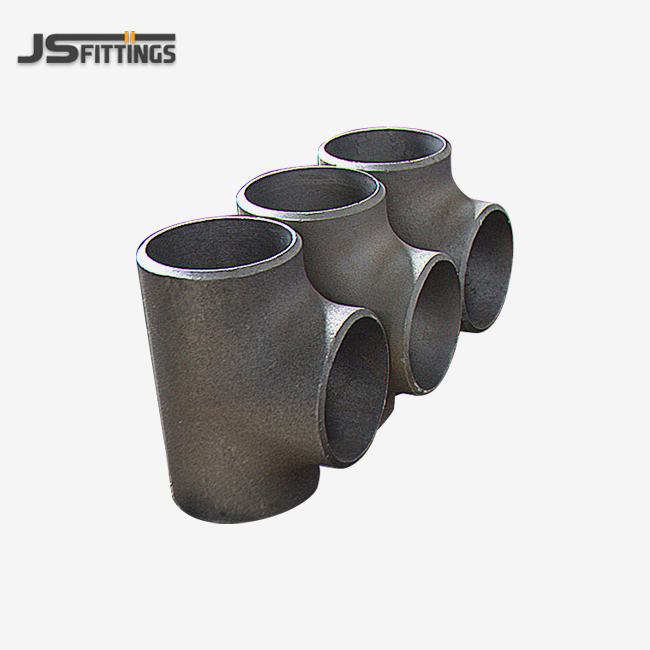

JS FITTINGS brings over decades of manufacturing excellence to serve as your trusted China carbon steel ERW pipe factory supplier. We produce Steel Pipes, Butt-weld Fittings, and Flanges with distinction.

We understand the Southeast Asian market intimately, having delivered numerous projects on time with full documentation support (Form E for duty benefits). Our facilities are ISO 9001 and PED certified, ensuring every pipe we ship meets global safety standards.

FAQ

Q1: What is the main difference between ERW and Seamless pipes?

The main difference is the manufacturing process. ERW (Electric Resistance Welded) pipes have a longitudinal weld seam and are made from steel coils, offering better wall thickness consistency and lower cost. Seamless pipes are extruded from solid billets, having no seam, making them suitable for higher pressure ratings.

Q2: How can I verify the quality of the pipes before shipment?

You should request the Mill Test Certificate (MTC), which includes chemical and mechanical properties. You can also hire a Third-Party Inspection agency (like SGS or BV) to inspect the goods at our factory before loading.

Q3: What is the delivery time to Southeast Asia?

Production usually takes 15-30 days depending on quantity. Shipping time from China to most Southeast Asian ports is very short, typically ranging from 7 to 15 days.

Partner with JS FITTINGS for Your Carbon Steel ERW Pipe Requirements

JS FITTINGS brings over 40 years of manufacturing excellence to serve as your trusted China carbon steel ERW pipe factory supplier. Our ISO 9001-certified facilities and comprehensive product range ensure reliable supply chain solutions for your most demanding projects. With proven expertise serving clients across Southeast Asia and beyond, we understand the critical importance of timely delivery, consistent quality, and competitive pricing in today's market environment. Contact our team at admin@chinajsgj.com to discuss your specific requirements and discover how our customization capabilities and technical expertise can enhance your project success. Visit chinajsgj.com to explore our complete product portfolio and quality certifications.

References

1. American Society of Mechanical Engineers. "ASME B16.9-2018: Factory-Made Wrought Buttwelding Fittings." ASME International, 2018.

2. European Committee for Standardization. "EN 10253-2:2020 Butt-welding Pipe Fittings - Part 2: Wrought Carbon and Ferritic Alloy Steels for General Use." CEN Publishing, 2020.

3. International Organization for Standardization. "ISO 3183:2019 Petroleum and Natural Gas Industries - Steel Pipe for Pipeline Transportation Systems." ISO Publications, 2019.

4. Steel Construction Institute. "Electric Resistance Welded Steel Pipes: Manufacturing Processes and Quality Standards." SCI Publication P394, 2021.

5. Asian Development Bank. "Infrastructure Development in Southeast Asia: Regional Assessment Report 2023." ADB Publications, Manila, 2023.

6. Chinese National Standards Committee. "GB/T 9711-2017 Petroleum and Natural Gas Industries - Steel Pipes for Pipeline Transportation Systems." Standards Press of China, 2017.

Learn about our latest products and discounts through SMS or email