It is important to follow the rules set by the industry and do things the right way when setting up and taking care of blind flanges. The system must be able to handle pressure, and the pipe ends must not touch. It's very important to set up the system correctly so that it works well and stays safe. You follow safety rules and keep your tools in good shape when you do maintenance the right way. It is important to install a blind flange the right way so that industrial pipe systems work well for a long time. Before you put it together, you should know how to check it and how to tighten the bolts correctly. It's also important to keep up with maintenance.

What blind flanges are made of, the different kinds, and how to use them?

This kind of pipe fitting is called a blind flange. It can be used to permanently seal the ends of a pipeline either way. Because of them, there is no flow. It keeps the pressure inside. The important parts don't have holes in the middle like most flanges do, which makes them different. Because of this, they are great for testing systems, letting maintenance workers in, and ending lines for good.

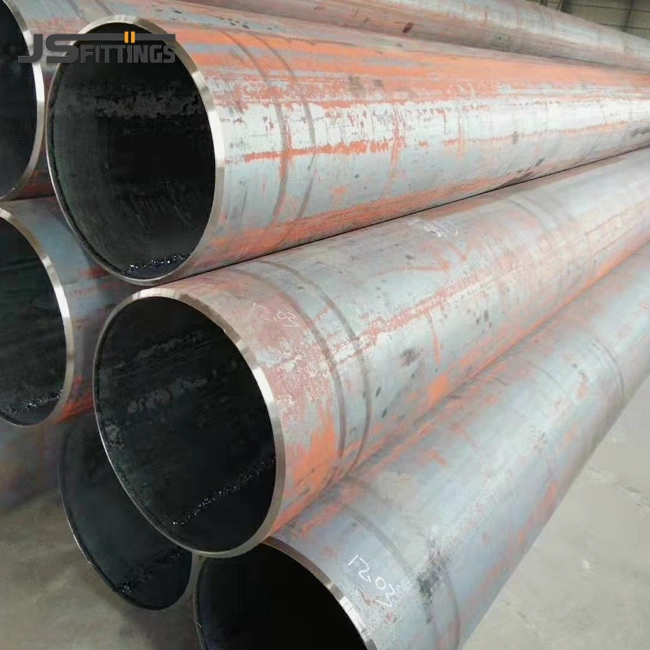

It really matters what you use for a blind flange because it determines how well it works and how long it lasts. When the pressure is right, versions made of carbon steel work well and cost less. On the other hand, ones made of stainless steel last longer and don't rust in harsh conditions. Everything made of alloy steel is stronger because its different parts work together. This lets it handle high temperatures and pressures. A new factory has painting lines that are run by machines that make sure the paint quality is always the same. The things will last longer and not rust anymore because of this.

When everyone around the world follows the rules, everything is safe and works with everything else. In North America, the ANSI B16.5 and ASME B16.47 standards say how big something can be and how much pressure it can hold. DIN and EN rules cover Europe's market. The finish on the flange face, the pattern of the bolt holes, and the pressure-temperature ratings are some of the most important things that these standards talk about. These have a direct impact on how well the installation works and how safe the work is.

Step-by-step instructions on how to put in a blind flange safely

Before putting in a blind flange, it's very important to make sure it's safe. If these checks aren't done, it could cost a lot of money and put people in danger. All the parts fit together well, and the seal works well because everything is where it should be.

Some important things need to be checked before an installation:

- Make sure that the thickness, the bolt circle's diameter, and the flange's outer diameter are all the right sizes for the system by checking them again. Make sure the bolt holes are straight and that the parts that go with them fit well. Make sure you check the pressure class ratings against the system needs before you start. You might fail very badly and make a mess if you don't.

- Set Up the Surface: Clean all the surfaces that will touch each other with the right tools and cleaners. Get rid of the rust, scale, and old gasket material. Look at the flanges' faces for any damage, like scratches or pits, that could weaken the seal. To get the right surface finish, make sure you follow the rules.

- Pick a gasket material that works with the press and how it will be used. Then look at it very carefully. Make sure that the gasket's sizes match what the flange needs. Check for flaws, make sure it's the right hardness, and make sure that's how it can be stored.

After these steps, you'll be ready to set up. Get rid of problems that appear often and prepare your business to be successful in the long term. When everything is ready, safety issues, leaks, and failures that happen too soon are less likely to happen.

It is done by following well-known rules in the field. These rules make sure that the installation always works the same way. Put the blind flange against the surface it will fit against first. Check that the gasket is where it should be and that it is lined up right. When you put the bolts in for the first time, make sure there are even gaps around the circle of bolts. Pull them tighter by hand. Ask the person who made it how to grease the threads on the bolts and the bearings.

When you tighten the bolts, pay close attention to the torque specs and the order in which they should be tightened. A calibrated torque wrench and cross-pattern tightening sequences should be used to make sure that the stress is spread out evenly across the face of the flange. Even if you tighten the gasket more than once with more and more torque, it won't come loose from the joint. Also, this makes sure that everywhere the pressure is the same. According to the manufacturer and any pipe codes that are in place, the last torque numbers should match.

How to Make Sure Blind Flanges Last a Long Time?

Blind flanges stay in good shape for their whole operational lifecycle when they have good maintenance programs in place. In this way, they don't break down without warning, and it's longer between service calls. Protocols for regular inspections find problems early on, before they get worse, cost a lot, or put people in danger.

Techniques for visual inspection are the building blocks of good monitoring for maintenance. You should look at the surfaces of the flanges once a month for corrosion, cracks, or other mechanical damage. Look for stains, mineral deposits, or crystalline structures that show moving process media that could mean there is a leak near the gaskets. When you check the bolts for corrosion, thread damage, or loosening that could weaken the joint, write them down and report them.

Modern ways of inspecting make it easier to find things that you can't see with your own eyes. When you measure ultrasonic thickness, you can see how much material is being lost due to corrosion or erosion, which is especially important in harsh service environments. When you look at something normally, you might not see cracks on the surface or close to the surface that are found by magnetic particle inspection. These methods help create condition-based maintenance plans that get the most out of the time and money spent on maintenance.

Regular maintenance checks look for and fix common types of failures before they have an effect on how the system works. Temperature cycling, the compression set of the gasket, and the relaxation of the material should all be taken into account in plans for re-torquing bolts. When you clean the flange, you need to think about how the material will react with the water and the environment for a long time. Stainless steel flanges need to be cleaned in a different way than carbon steel ones so that they don't rust and the surface stays clean.

A Look at Different Blind Flanges to Help You Pick the Best One

To pick the best blind flange configurations, you need to know what the application needs and how the different design choices affect performance. Each type of flange has its own advantages that make it best for certain applications and installation restrictions.

Both blind flanges and blind plates can be used to end a pipeline in different ways. Blind flanges can be put in place permanently and can be bolted together in standard ways. On the other hand, blind plates are cheaper and can be used to seal things temporarily. Any size of blind flange can handle the same amount of pressure and doesn't cause any issues with existing pipe systems. Because they are built in a standard way, they can work with parts from different manufacturers, which makes buying them easier.

When picking materials, you need to think about the cost, the performance needs, and the environment where they will be used. There are affordable options made of carbon steel for common industrial uses that are subject to moderate corrosion. Stainless steel types are great for places that need to be clean and don't rust, like chemical, pharmaceutical, and food processing plants. You can get the best performance for each service condition while still meeting industry standards if you have a choice of materials.

Customized items can help with issues in your operation that regular ones can't when you need them to. Certain industrial processes and pieces of equipment can connect with the help of different pressure ratings, special coatings, and non-standard sizes. When there are a lot of moving parts, custom solutions are often cheaper than field modifications or assemblies with many parts.

There are some things you should think about before you buy blind flanges in a B2B market

When you strategically buy things, the quality of the things you buy will not change. You know you can depend on them. Because of this, the total cost of ownership goes down. Check out more than just the price to get a good idea of the seller. This is because the value has to last.

You should find out how well a supplier can make things, handle quality, and back up certification before you hire them. If someone is ISO 9001 certified, they always handle quality in the same way. People who have been trained by ASME and API know how to use pipes and pressure vessels. This really helps with projects where you need to keep track of things and give proof to someone else.

There are many costs that come with owning something. How much did it cost to buy? How much will it cost to set up and fix? How long do you think it will last? Things that are made with better materials and methods usually last longer and need less upkeep, so it's worth the extra money up front. People who buy in bulk and agree to long-term deals can save a lot of money on big projects and regular business needs.

When planning lead times, how much stock there is, when things need to be shipped, and the production schedule are all taken into account. Custom forms may take longer to get if you need special materials or want to change the product's size or shape. It's faster and cheaper to send things that are made in the same area. This can also help government projects get the content they need from people in the area.

FAQs

Q1: How can I keep blind flanges from leaking? Why do they happen?

A: The bolts weren't tight enough, the wrong gasket was used, or the seals on the surfaces were broken. This is why most blind flange leaks happen. Make sure the flange faces are clean and not broken before you put the gaskets on. Also, use calibrated tools to make sure the bolts are tightened in the right order. If you do these things, this won't happen.

Q2: In a business setting, how often should blind flanges be checked?

It relies on how important the service is to you and how often you use it. In any case, industrial applications should be quickly looked over once a month and more carefully once a year. If the service area has a lot of corrosion, high pressure, or high heat, it may need to be checked more often.

Question 3: Can blind flanges be used again after being taken out of service?

A: Yes, blind flanges can be used again after being fixed and checked to make sure everything is okay. Check the sizes again and look for threads that are broken or too long in the bolt holes. Check the flange faces for damage too. Always use new bolts and gaskets, and make sure the flange can handle the extra weight.

Conclusion

It is important to always keep an eye on things, follow the right steps, and use good materials when installing and taking care of blind flanges. If you know about the different kinds of flanges, the rules that apply, and the features of the materials used, you can buy things that are better made and last longer. You can keep the system safe to use and avoid common failure modes by following standard installation steps and making sure you use good gaskets and the right torque times. Maintenance programs find problems early on, before they get too bad. The total cost of ownership goes down, and the product lasts longer thanks to these programs. Supply chains that are reliable help projects succeed and operations run smoothly. A smart way to buy things that focuses on the credentials and support for certifications of suppliers makes this possible.

Partner with JS FITTINGS for Premium Blind Flange Solutions

Reliable blind flange performance starts with selecting the right manufacturer who understands your operational challenges and quality requirements. JS FITTINGS brings over 40 years of manufacturing expertise to deliver high-performance pipe fittings that meet the most demanding industrial applications. Our automated painting production line ensures consistent coating quality, while our diverse material options accommodate everything from standard carbon steel to specialized alloy compositions.

Our commitment to compliance with international standards, including ISO 9001, CE, and GOST-R certifications, provides the quality assurance that procurement professionals require. Whether you need standard configurations or customization for special requirements, our engineering team works closely with clients to develop optimal solutions that minimize project risk and ensure long-term performance.

As a trusted blind flange supplier serving clients across the Middle East, South America, Europe, and Asia, we understand the importance of certification support for complex industrial projects. Our comprehensive documentation packages and material traceability systems streamline approval processes and ensure regulatory compliance. Ready to discuss your blind flange requirements and discover how our solutions can optimize your project outcomes? Contact us at admin@jsfittings.com for expert consultation and competitive pricing on your next procurement initiative.

References

1. American Society of Mechanical Engineers. "ASME B16.5 - Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard." ASME International, 2020.

2. Bickford, John H. "An Introduction to the Design and Behavior of Bolted Joints." CRC Press, 2018.

3. Gupta, Ramesh C. "Piping Materials Guide." McGraw-Hill Education, 2019.

4. International Organization for Standardization. "ISO 7005-1:2011 Metallic flanges - Part 1: Steel flanges." ISO Standards, 2011.

5. Nayyar, Mohinder L. "Piping Handbook." McGraw-Hill Education, 2019.

6. Singh, Kiran. "Industrial Pipeline Engineering and Construction." Butterworth-Heinemann, 2017.

_1758870722907.webp)