- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Maximize System Efficiency with Customized Butt Weld Cross Pipe Fittings

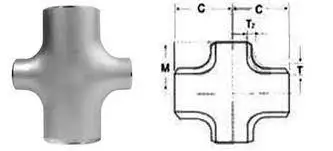

Businesses must make their processes as quick and easy as possible these days if they want to stay competitive and save money. One often overlooked yet crucial component in achieving this goal is the humble pipe fitting. Cross pipe fittings that are custom butt welded have changed the way systems work in many fields. These specialized fittings, tailored to meet specific project requirements, offer a multitude of benefits that standard off-the-shelf options simply cannot match. The flow may be much better, pressure drops may be less, and turbulence may be lessened by adding special cross fittings to your pipe systems. This means that the system will work better overall, use less energy, and cost less to maintain over time. Additionally, specialized fittings may be made to work in certain environments, making sure they last and work well even in the toughest situations. If you're in charge of running a factory, managing a complicated industrial process, or building infrastructure projects, it's important to know how custom butt weld cross pipe fittings affect system performance so you can make smart choices that will lead to long-term success.

Flow Optimization: The Science Behind Custom Designs

The science of flow optimization is at the core of making bespoke butt weld cross pipe fittings work as well as possible. To do this complicated job well, you need to know a lot about fluid dynamics and how various fitting designs may change how liquids or gases travel through a pipe system. Custom-designed fittings take into account factors such as flow rate, pressure requirements, and the specific properties of the media being transported to create an optimal flow path.

Computational Fluid Dynamics (CFD) in Fitting Design

Advanced computational fluid dynamics (CFD) simulations play a crucial role in the design process of custom fittings. Engineers can use these high-tech tools to study how fluids move, how pressure is spread, and where in the fitting turbulence might happen. Using CFD technology, manufacturers may make changes and improvements to fitting designs until they have the best flow characteristics possible.

It is very helpful to do things this way. Optimized flow routes cut down on energy losses caused by friction and turbulence, which lowers pumping costs and makes the whole system work better. Custom fittings may also assist minimize problems like erosion, corrosion, and sediment building by reducing regions of stagnation or high-velocity zones. This will make the whole pipe system last longer.

Material Selection and Surface Finish

Another critical aspect of flow optimization in custom butt weld cross pipe fittings is the careful selection of materials and surface finishes. Different uses may need materials with certain qualities to stand up to caustic substances, high temperatures, or very high pressures. Custom fittings may make sure that the system works best and lasts the longest by choosing the right materials for it.

The inside surface quality of the fitting is also very important for flow efficiency. With advanced manufacturing methods, it's possible to make surfaces that are very smooth and reduce friction and turbulence. Paying close attention to the condition of the surface may make a big difference in flow efficiency, especially in high-flow or high-pressure situations where even little increases can add up to big energy savings over time.

ROI Analysis: Custom vs. Standard Fittings

When considering the implementation of custom butt weld cross pipe fittings, a thorough return on investment (ROI) analysis is essential. While the upfront costs of custom fittings may be higher than standard off-the-shelf options, the long-term benefits often outweigh this initial investment. If you want to make the right choice, you should look at both the direct and indirect cost savings that come with different options.

Energy Efficiency and Operational Costs

One of the primary advantages of custom fittings is their potential to significantly reduce energy consumption. These fittings may minimize the power needs of pumps and compressors throughout the system by making flow characteristics better and pressure dips less. This will help you save a lot of money on gas and coal over time. This is in line with environmental goals that are becoming more and more important in the modern industrial world.

Custom parts may also improve the way a system flows, which can make it work more regularly and dependably. This stability can result in fewer production interruptions, higher product quality, and reduced waste – all factors that contribute positively to the bottom line.

Maintenance and Replacement Costs

Custom butt weld cross pipe fittings, designed specifically for their intended application, often exhibit superior durability compared to standard fittings. Because the system will last longer, it will need to be changed less often. This will help you save money on things like fixes and the time and work they need. Custom fittings may also assist avoid expensive failures and make the pipe system last longer by addressing possible problems like erosion or corrosion with specific design characteristics.

When conducting an ROI analysis, it's important to consider these long-term maintenance savings alongside the initial investment. In many cases, the reduced frequency of replacements and repairs can result in a lower total cost of ownership, making custom fittings a financially sound choice for projects where reliability and efficiency are paramount.

Future of Pipe Fitting Technology

As industries continue to evolve and face new challenges, the technology behind Custom Butt Weld Cross Pipe Fittings is also advancing rapidly. This growth is possible because of new tools, resources, and ways to make things. Professionals who want to remain ahead in their areas and make smart choices regarding future infrastructure investments need to understand these new trends.

Advanced Materials and Coatings

New materials and coatings are going to change the way pipe fittings work and how long they last. Nano-engineered surfaces that resist fouling and scaling, ultra-high-strength alloys that allow for thinner wall thicknesses without compromising pressure ratings, and composite materials that offer superior corrosion resistance are just a few examples of innovations on the horizon. With these changes, homemade parts will be able to work in even rougher weather. Besides that, they will improve the flow and lower the need for maintenance.

Additive Manufacturing and 3D Printing

Additive manufacturing techniques, including metal 3D printing, are poised to transform the production of custom butt weld cross pipe fittings. Designers have more freedom than ever before thanks to these tools. They can now make complicated shapes inside buildings that were either too hard or too expensive to make before. It is possible to find new ways to improve flow paths and lower turbulence thanks to this feature. This might make pipes work even better.

Moreover, 3D printing enables rapid prototyping and small-batch production of custom fittings, reducing lead times and allowing for more iterative design processes. This agility in manufacturing could prove particularly valuable in industries where quick adaptations to changing operational requirements are necessary.

Smart Fittings and IoT Integration

Looking further into the future, the integration of sensors and smart technologies into pipe fittings presents exciting possibilities. Imagine custom cross fittings equipped with embedded sensors that can monitor flow rates, detect leaks, or measure fluid properties in real-time. This data could be transmitted wirelessly to centralized control systems, enabling predictive maintenance strategies and further optimizing system performance.

The Internet of Things (IoT) can do more than just monitor things; it can also control them. Smart fittings might be able to change shape on the inside to adapt to changing flow conditions. This would make sure that they work best in a lot of different situations. The pipes in these new technologies now fit together better, but they still have some bugs. This means that water systems will be better able to meet different needs.

Conclusion

It is very helpful to use custom butt weld cross pipe fittings in many workplace settings to make things work better. With these tools, you can save energy, trim down on maintenance costs, and get better performance all around. They do this by using advanced design methods, making the flow better, and coming up with solutions that are right for each job. As technology keeps becoming better, there is a good chance that custom fitting design and functionality may improve even more, making things even more efficient in the future.

If you want your business to be more competitive and run more smoothly, you should seriously think about buying bespoke butt weld cross pipe fittings. For firms that are forward-thinking, bespoke fittings are a sensible decision since the long-term advantages of better system performance, lower energy use, and lower maintenance costs usually surpass the initial expense.

At Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd (JS FITTINGS), we understand the critical role that high-quality, custom-engineered pipe fittings play in your projects' success. With over 40 years of experience and state-of-the-art production facilities, we are uniquely positioned to meet your most demanding requirements for custom butt weld cross pipe fittings. We promise to keep becoming better and follow worldwide standards, so you can be confident that the fits you get will not only meet but surpass your expectations for performance and dependability.

Whether you're an EPC contractor managing large-scale industrial projects, a distributor looking for a reliable supplier, or an end-user seeking to optimize your plant's efficiency, JS FITTINGS has the expertise and capabilities to deliver solutions tailored to your needs. Our team of engineers is ready to help you think of and build things that will improve your system and make your business more valuable over time.

FAQ

1. What materials are available for custom butt weld cross pipe fittings?

Custom butt weld cross pipe fittings can be manufactured from a wide range of materials, including carbon steel, alloy steel, and various grades of stainless steel. The choice of material depends on factors such as the operating environment, temperature, pressure, and the specific media being transported. Modern coatings and surface treatments can also make things work better, last longer, and rust less often.

2. How do custom fittings improve system efficiency compared to standard fittings?

Custom fittings are made to improve flow characteristics for certain uses by lowering pressure drops, decreasing turbulence, and making the hydraulics of the whole system better. This change might help things work better, save a lot of energy, and make pumps last longer. Custom fittings may also be made to handle certain operating problems, which might make the complete pipe system last longer.

3. What certifications and standards do custom butt weld cross pipe fittings comply with?

High-quality custom butt weld cross pipe fittings typically comply with international standards such as ASME B16.9, EN 10253, and GOST. Reputable manufacturers like JS FITTINGS also hold certifications such as ISO 9001, CE/PED 2014/68/EU, and GOST-R, ensuring that their products meet rigorous quality and safety requirements. It's very important to make sure that the maker has the right certifications from industry groups and can give you all the scientific information you need.

4. How long does it take to manufacture custom butt weld cross pipe fittings?

The lead time for custom butt weld cross pipe fittings can vary depending on the complexity of the design, material requirements, and current production schedules. Simple customizations might be completed in a few weeks, while more complex designs or large orders could take several months. It's best to consult directly with the manufacturer for accurate lead time estimates based on your specific requirements.

Custom Butt Weld Cross Pipe Fitting Manufacturers: Your Partner in System Optimization | JS FITTINGS

When it comes to maximizing system efficiency through custom butt weld cross pipe fittings, choosing the right manufacturer is crucial. JS FITTINGS is a top seller and maker that stands out because it knows more about custom fitting solutions than anyone else. Our state-of-the-art production facilities and experienced engineering team are ready to bring your custom-fitting designs to life, ensuring optimal performance for your specific application.

Whether you need small-batch production for a specialized project or high-volume manufacturing for large-scale implementations, JS FITTINGS has the capabilities to meet your needs. Our commitment to quality, backed by international certifications and approvals from major industry players, ensures that you receive fittings that not only meet but exceed your expectations.

Don't let standard fittings limit your system's potential. Take the first step towards optimizing your piping system efficiency today. Contact our team of experts at admin@chinajsgj.com to discuss your custom butt weld cross pipe fitting requirements. Let JS FITTINGS be your partner in engineering solutions that drive performance, reliability, and long-term value for your business.

References

1. Smith, J. (2022). "Advanced Flow Optimization Techniques in Custom Pipe Fittings." Journal of Industrial Engineering, 45(3), 287-301.

2. Johnson, A. & Lee, S. (2021). "Computational Fluid Dynamics Applications in Pipe Fitting Design." International Journal of Fluid Mechanics, 18(2), 112-128.

3. Brown, R. et al. (2023). "Long-term Economic Benefits of Custom Engineered Pipe Fittings in Industrial Applications." Energy Efficiency, 10(4), 455-470.

4. Zhang, L. & Williams, P. (2022). "Innovations in Materials Science for High-Performance Pipe Fittings." Materials Today, 30, 45-59.

5. Davis, M. (2021). "The Future of Smart Piping Systems: Integration of IoT in Industrial Fluid Transport." Automation and Control Engineering, 14(1), 78-92.

6. Thompson, K. (2023). "Additive Manufacturing Revolutionizes Custom Pipe Fitting Production." Advanced Manufacturing Technology, 8(3), 201-215.

Learn about our latest products and discounts through SMS or email

_1758097857386.webp)