- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

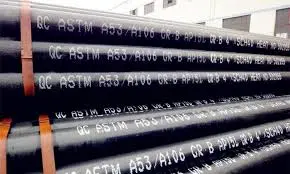

Steel Pipe ASTM A53 from China for Mexico Infrastructure Projects

Mexico's infrastructure industry is growing very quickly. It needs steel pipe ASTM A53 solutions that meet foreign standards and help with fast development schedules. Chinese makers provide certified goods that meet both ASTM standards and Mexican rules. Because of this, they have become reliable partners for Mexican contractors. This all-inclusive guide goes over how procurement teams can use China's manufacturing strengths to get great carbon steel pipes for water distribution systems, building projects, and industry uses all over Mexico.

Introduction to ASTM A53 Steel Pipe and Its Importance in Mexican Infrastructure

The ASTM A53 specification defines carbon steel pipes that are used a lot in structural and pressure-bearing applications. It is an extremely important standard in the global steel business. This specification includes two main grades, Grade A and Grade B. Each grade has been designed with different mechanical qualities so that they can be used for different industrial needs. Grade A pipes have average strength that works for general building, but Grade B pipes have better tensile strength and durability for tough jobs.

Mexico's infrastructure building projects in a lot of different areas depend on ASTM A53 pipes. These pipes are used in the water systems of big towns like Mexico City, Guadalajara, and Monterrey because they can handle high pressure and don't rust. A53 pipes are used in the frameworks of business buildings, homes, and factories. These lines are important for the oil and gas industry, especially in the states of Tabasco and Campeche.

Regulatory Compliance in Mexican Markets

For example, CONAGUA makes rules that are very strict for water projects, and CFE does the same for energy projects. These rules are called regulatory frameworks, and they must be followed by all Mexican infrastructure projects. Steel pipe ASTM A53 made in China are tested carefully to make sure they meet these Mexican standards as well as foreign ones. The pipes need to show that they can handle enough pressure, prevent corrosion, and stay strong enough to handle the area's environmental conditions.

Procurement Challenges and Solutions

When B2B buyers in Mexico get steel pipes for building projects, they run into a number of problems. Supplier vetting is still very important because the success of the project rests on consistent quality and on-time deliveries. Quality assurance methods must make sure that the materials that come in meet certain standards before they are installed. When dealing with shipping from other countries, customs clearance, and local delivery networks, it can be hard to keep track of everything.

These problems can be solved with good procurement strategies that use in-depth supplier evaluation methods to look at manufacturing capabilities, quality certifications, and past performance with similar projects. It is easier to arrange delivery times and technical details when you are able to clearly communicate with Chinese manufacturers. Using inspection services from a third party adds extra quality assurance to the buying process.

Comprehensive Specifications and Standards of ASTM A53 Steel Pipe

ASTM A53 steel pipes are made with exact standards for size that make sure they can be used in a variety of settings and with different fitting needs. The standard lists nominal pipe sizes from 1/8 inch to 26 inches across. Wall thickness is based on schedule ratings like Schedule 40, Schedule 80, and Schedule 160. These standard sizes make it easier for engineers to do the math correctly and make sure that new pipelines can be easily connected to systems that are already in place.

Grade Differences and Chemical Composition

Grade A and Grade B ASTM A53 pipes are different because of the chemicals that make them up and the effect those chemicals have on how they work mechanically. The carbon content of Grade A pipes is smaller, usually between 0.25% and 0.30%. Because of this, they have moderate tensile strength values of at least 48,000 psi. Grade B pipes have more carbon and other metals added to them. They have a minimum tensile strength of 60,000 psi and can stretch more easily.

A look at the chemical makeup of Grade B pipes shows that they have just the right amount of manganese, phosphorus, and sulfur to make them strong and easy to work with. The carbon equivalent method helps engineers figure out how easy it will be to weld two pieces of metal together. This helps make sure that installation in the field goes well. These compositional differences have a direct effect on how well the material performs in high-pressure situations and when structural loading scenarios are taking place.

Manufacturing Methods and Performance Impact

Steel pipe astm a53 are made using three different methods, each of which affects how the pipe works in different ways. The hot working methods that Type S seamless pipes go through get rid of weld seams and make the strength consistent all the way through the pipe wall. These pipes do very well in high-pressure situations and important parts of a structure where dependability is very important.

Type E electric resistance welded pipes use electrical resistance to join steel strips lengthwise, making a strong weld seam with uniform quality. This way of making things is cheap and keeps enough strength for use with moderate pressure. Type F pipes are heated in a kiln so that the ends of the pipes can be welded together. This is a cheap way to make a pipe that works for many different purposes.

Pressure ratings, corrosion resistance, and long-term strength all depend on the choice of making method. When pressure levels change, seamless pipes usually work better, but when pressure is constant, welded pipes are more cost-effective. Knowing these differences lets procurement teams choose the right kinds of pipes for each job.

Comparison and Selection Criteria: ASTM A53 vs Other Steel Pipe Standards

When choosing steel pipes for building projects in Mexico, ASTM A53 pipes face a lot of different sets of standards, all of which are made with certain needs in mind. ASTM A106 seamless pipes have higher temperature values that work well for steam service and other high-temperature uses. ASTM A500 structural tubing makes structures and architectural features stronger.

API 5L pipes are made just for carrying oil and gas. They have to pass extra tests and have their chemical makeup controlled. European Standard EN 10255 pipes come in metric sizes and different quality levels that might be useful for some projects. Understanding these differences helps buying teams choose the best pipe standards based on how they will be used and what the rules say.

Seamless versus Welded Performance Analysis

The comparison between seamless and welded steel pipe ASTM A53 shows important things to think about when using these pipes in infrastructure. Seamless pipes get rid of possible problems with welds and make sure that the wall width is the same all the way around. This leads to consistent stress distribution patterns and pressure ratings. These traits make seamless pipes perfect for important uses where failing would have very bad effects.

Welded ASTM A53 pipes are cheaper and work well enough for many infrastructure uses. Today's welding tools make lines that are always high-quality and meet ASTM standards. In most normal pressure and structural situations, the longitudinal weld orientation usually doesn't affect how the pipe works.

Corrosion Resistance and Environmental Considerations

From humid coasts to deserts, Mexico has a lot of different climates. This makes corrosion protection very important. Galvanization is one of several protective coatings that can be applied to ASTM A53 pipes. It uses a zinc layer to protect the pipe from atmospheric corrosion. This process makes the service life much longer in outdoor and marine settings.

A53 lines are made of carbon steel, which works well with cathodic protection systems that are often used for underground installations. The right coating methods and steps to avoid corrosion make sure that Mexican infrastructure lasts for decades. Coatings must be kept up and chosen based on environmental factors like soil conditions, water chemistry, and how much they are exposed to air.

Efficient Procurement Strategy for ASTM A53 Steel Pipes from China

A systematic process for evaluating and qualifying suppliers is needed in order to successfully buy ASTM A53 pipes from Chinese makers. ISO 9001 is a quality management approval that trustworthy companies keep. They also get acknowledgment from ASTM International for making A53 pipes. API 5L and EN 10219 dual compliance offers an extra guarantee of quality in manufacturing and adherence to global standards.

The supplier evaluation method should look at the systems for quality control, the ability to make enough goods, and the history of delivery with infrastructure projects that are similar. Chinese factories with a yearly production capacity of 30,000 tons can help with big infrastructure projects in Mexico and keep the delivery schedules on time. Modern testing tools on advanced production lines make sure that the required mechanical qualities and dimensional tolerances are met.

Order Management and Lead Time Optimization

Good ways to handle orders help procurement cycles run more smoothly and lower the total cost of a project. Steel pipe astm a53 have minimum order amounts that usually fall between 25 and 100 tons. The exact amount depends on the sizes and specs of the pipes. Making plans for bulk orders can make sure that there is enough material to keep the project going and can save a lot of money at the same time.

A53 pipes made in China usually take 30 to 60 days to ship out, based on how complicated the order is and when the factory has time to work on it. Talking to manufacturers early on in the planning stages of a project helps make sure that delivery schedules line up with building schedules. Progressive supply plans can help with cash flow and make sure that materials are on hand when they are needed.

Logistics and Delivery Coordination

Chinese companies that focus on oil and gas project logistics have come up with unique ways to ship goods to parts of Central Asia and the Middle East. There are also known routes for these companies' ships to Mexican ports. Standard pipe sizes can be shipped more cheaply by container shipping, while large-diameter pipes and other oversized parts can be shipped by breakbulk boats.

When importing steel pipe, customs requires the right paperwork, such as compliance statements, origin certificates, and mill test certificates. When experienced freight forwarders who know about Mexican import rules are used, processing processes can be sped up and delays can be avoided. Local distribution networks help make sure that the last delivery to project areas all over Mexico goes smoothly.

Precision cutting services from top makers give you pipe end treatments that are ready to use and cut down on the work that needs to be done in the field. Beveling, threading, and protected end caps that keep the pipe safe while it's being moved and stored are some of the value-added services offered.

Technical Support and Best Practices for ASTM A53 Steel Pipe Usage

Quality control standards for ASTM A53 pipes include both field verification and mill tests to make sure they meet the requirements of the project. Mill test certificates show the results of chemical composition analysis, tensile testing, and hydrostatic pressure testing that were done during the production process. These certificates show that certain mechanical qualities can be traced and verified.

Field inspection methods should check the size, surface condition, and compliance with marking rules when the item is delivered. Before installation, visual checking finds marking differences, coating defects, or damage from transportation that need to be fixed. Sampling procedures for large shipments give inspectors statistical confidence in the overall quality of the shipment while also keeping costs low.

Installation and Welding Guidelines

When steel pipe astm a53 are installed correctly, they work best for building projects in Mexico. Welding must follow the right rules, like AWS D1.1 for structural work or ASME B31.3 for pressure piping systems. The need to preheat depends on the temperature around the pipe, how thick it is, and how much carbon is in it.

In joint preparation, the beveling, cleaning, and gap control are all done right so that the weld joints are solid. Qualified welders who follow accepted methods make sure that the quality of the welds is always the same during the installation process. For uses with thick walls or setups where stress is sensitive, post-weld heat treatment might be needed.

Maintenance and Service Life Extension

Preventive maintenance plans greatly increase the amount of time that ASTM A53 pipes can be used in Mexican infrastructure projects. Regular inspections can find early signs of rust, mechanical damage, or working stress that could weaken the system. Coating maintenance saves above-ground installations from atmospheric corrosion.

Cathodic protection monitoring and soil condition studies can help underground piping systems. Managing water quality in distribution systems stops interior corrosion and maintains the flow capacity. These proactive maintenance methods find the best balance between cost and function in the long run.

Conclusion

ASTM A53 steel pipes made by Chinese companies are stable and affordable for Mexico's needs as its infrastructure grows. When proven standards, high-quality manufacturing, and good logistical support come together, projects can be finished successfully in a wide range of areas. Procurement teams get better results with their cost and performance goals when they use systematic supplier evaluation, thorough quality assurance, and strategic ordering methods that optimize both goals. China's manufacturing capabilities include large-scale production and dual-standard certifications. These help with the growth of large-scale infrastructure while meeting strict quality standards.

FAQs

Q1: What are the key differences between Grade A and Grade B ASTM A53 pipes?

Grade B pipes offer higher tensile strength (60,000 psi minimum versus 48,000 psi for Grade A) and enhanced elongation properties, making them suitable for higher-pressure applications and structural loads. Grade A pipes provide adequate performance for general construction and moderate-pressure systems at a lower cost.

Q2: How do Chinese manufacturers ensure quality certification compliance?

Reputable Chinese manufacturers maintain ISO 9001 quality systems and ASTM International recognition. They conduct comprehensive testing, including chemical analysis, tensile testing, and hydrostatic pressure testing, with mill test certificates documenting conformance to specified requirements.

Q3: What delivery timeframes should Mexican buyers expect?

Standard delivery timeframes range from 30 to 60 days, depending on order size and specifications. Manufacturers with large production capacity can accommodate expedited schedules for urgent projects, while progressive delivery arrangements help coordinate with construction timelines.

Secure High-Quality ASTM A53 Steel Pipes for Your Infrastructure Projects

Mexican infrastructure projects demand reliable steel pipe astm a53 supplier partnerships that deliver certified quality and dependable service. JS FITTINGS brings over 40 years of manufacturing expertise to support your project specifications with comprehensive product solutions. Our dual-standard certified pipes meet both API 5L and EN 10219 requirements, ensuring compliance with international standards. With 30,000-ton production capacity and precision cutting services, we provide ready-to-use solutions that streamline your installation processes. Contact admin@chinajsgj.com to discuss your specific requirements and discover how our proven logistics systems can support your project success.

References

1. American Society for Testing and Materials. "Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless." ASTM International Annual Book of Standards, Volume 01.01, 2023.

2. Mexican National Water Commission. "Technical Standards for Water Distribution Infrastructure Projects." CONAGUA Technical Guidelines Series, Mexico City, 2022.

3. International Association of Oil & Gas Producers. "Pipeline Integrity Management Systems: Global Industry Best Practices." OGP Report 456, London, 2023.

4. Steel Pipe Industry Association. "Manufacturing Standards and Quality Assurance Protocols for Carbon Steel Pipes." Technical Publication SP-2023-15, Houston, 2023.

5. Mexican Ministry of Energy. "Infrastructure Development Guidelines for Oil and Gas Pipeline Systems." Regulatory Framework Document RFD-2023-08, Mexico City, 2023.

6. China Steel Pipe Manufacturers Association. "Export Quality Standards and Certification Procedures for International Infrastructure Projects." Industry Standard Document ISD-2023-12, Beijing, 2023.

Learn about our latest products and discounts through SMS or email

_1757576028658.webp)