The best OEM/ODM carbon steel fittings and flanges makers in China will be Jianzhi Group, Shanxi Solid Industrial, Cangzhou Steel Pipe Group, and Wenzhou Topnotch Machine. They are excellent at making elbow fittings, tee fittings, and reducer fittings, and their certifications meet ANSI standards. For 40 years, JS FITTINGS has been making high-quality slip-on flanges and butt weld pipe fittings. This makes the company stand out. These businesses help people from all over the world with cutting-edge welded connections and full industrial pipe solutions that meet pressure rating standards.

Learning the Best Ways to Make OEM/ODM Pipes for Industry

One important method used in the pipe fittings business is Original Equipment Manufacturing (OEM). Another is Original Design Manufacturing (ODM). Businesses can use designs that are already out there and still stay true to their brand through OEM partnerships. This type of relationship is more in-depth, so you can work on a product from the time you have an idea until it is delivered.

In the industrial piping sector, you need precise engineering and consistent quality. Although it is expensive, carbon steel is still the best material for many tasks because it is strong, lasts a long time, and isn't too expensive. Today, plumbing systems and factories use threaded fittings and socket weld connections that are very strict and meet DIN standards.

When you work together as an OEM or ODM, China's manufacturing ecosystem offers benefits that you won't find anywhere else. Because the country has modern infrastructure, skilled workers, and supply chains that are well linked, it is possible to make competitively priced seamless fittings. This skill is used to make a lot of different kinds of flanges, from simple ones to more complicated ones that are made just for you.

JS Fittings is the best OEM/ODM company for you

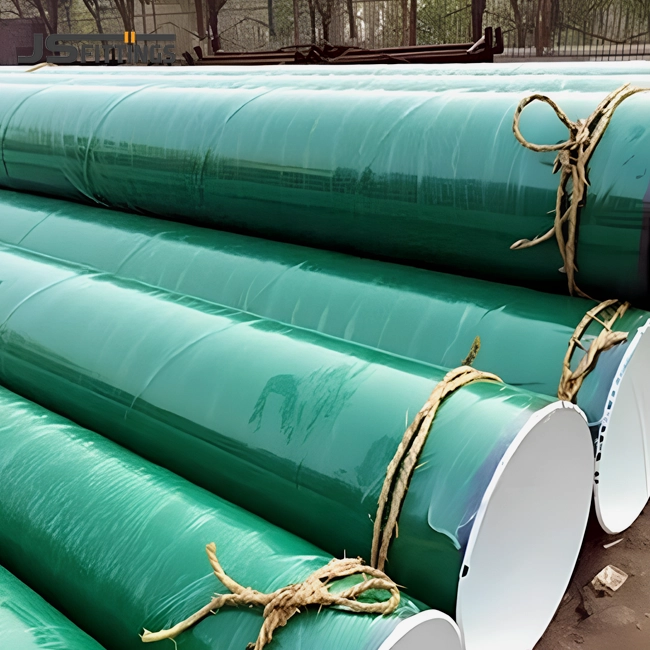

The 40 years of experience that Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd (JS FITTINGS) has in their field help them with every project they work on. We can make all sorts of carbon steel parts, from simple elbow fittings to complex custom assemblies, including Carbon Steel Fittings and Flanges, because we know how to make a lot of different things.

Our four state-of-the-art production lines all use cutting-edge technology to make welded connections and streamline the manufacturing process. There are strict rules that these factories follow for quality control to make sure that all of their goods meet international standards. There are ISO 9001, CE, and GOST-R certifications that back up our promise to be the best in global markets.

Research and development are what help us come up with new ideas. When clients come to us with operational problems, our engineering team works closely with them to find solutions. Partner groups in Asia, the Middle East, South America, and Europe all trust this method.

In markets with a lot of competition, we stand out because of how reliable our supply chain is. We have long-term agreements with suppliers of raw materials to make sure we always have access to good ones. We can keep prices low by changing the amount of production based on the needs of each project thanks to this network.

Complete solutions for customization for all usages

Customizing the physical design meets the specific installation needs of a wide range of industrial applications. Our engineering team changes the sizes, wall thickness, and connection requirements to fit the needs of each project. This includes being able to handle different pressures and requirements for corrosion resistance.

Features that are functional can change based on the operational environment. Our manufacturing processes can meet the needs of projects that need better temperature resistance or specific gasket materials that work well together. It is possible to make socket weld and butt weld configurations work better with certain installation methods.

Adding new technologies to existing ones makes all of them work better. Advanced metallurgy techniques make materials better while keeping their low cost. The people who work on our research team are always looking for new ways to make things that work better in tough situations.

Customizing brands helps our partners' strategies for positioning themselves in the market. Custom labels, packaging options, and paperwork all meet the needs of the brand. This all-around approach makes sure that integration into existing product lines goes smoothly.

Compliance customization takes into account the different rules and regulations that apply to markets around the world. We know how to meet ANSI standards, DIN specifications, and local certification needs. With this information, products are sure to have all the approvals they need for their target markets.

The ODM Advantage: Working together to create cutting-edge pipe fitting solutions

Through collaborative product development, ODM partnerships open up new ideas. Together with our clients, our engineering team finds market opportunities and creates solutions that meet unmet needs. This method has led to ground-breaking products, such as Carbon Steel Fittings and Flanges, that create whole new market segments.

Our ODM projects move forward with the help of market research. We look at new trends in using stainless steel, the needs of industrial pipes, and changes to the rules. This information helps developers make plans that put partners ahead of the competition.

Time-to-market times are sped up by making prototypes. Our ability to make rapid prototypes lets us test and improve things quickly. This iterative process makes sure that final products meet performance standards and improves the efficiency of production.

Protecting intellectual property keeps clients' investments safe during the development process. We follow strict rules about privacy and respect technologies that are owned by others. This promise builds trust and makes it easier for people to work together on sensitive projects in an open way.

Our tried-and-true OEM/ODM process: from idea to delivery

The project's parameters and performance standards are set during the initial consultation. Our technical team looks over the requirements, the expected timeline, and the budget. This thorough evaluation is the basis for partnerships that work well.

Design development takes ideas and turns them into detailed engineering drawings. Our CAD experts make detailed specifications that make manufacturing more efficient while still meeting performance goals. During this phase, regular reviews make sure that everything is in line with what the client wants.

Making a prototype lets you test design ideas in the real world. Our quality control team does thorough checks that include material analysis and pressure testing. Before full-scale production starts, this validation process finds ways to make things better.

Manufacturing scaling lets us use our advanced production skills. Quality control systems keep an eye on every step of the production process to make sure that all large orders are made the same way. Our skilled drivers stick to strict standards while meeting tight delivery times.

Products are ready to be shipped around the world after a final inspection and packing. Each part goes through a lot of tests to make sure it meets the requirements. Custom packaging solutions keep goods safe while they're being shipped and meet the branding needs of the client.

Why selecting JS Fittings for your next project is a smart move?

Cost optimization strategies lower the total cost of a project by making the manufacturing process more efficient. Because we buy in bulk and have strategic relationships with our suppliers, we can offer competitive prices without lowering the quality of our products, such as Carbon Steel Fittings and Flanges. This value proposition helps our partners do better in the market.

Through thorough testing protocols, quality assurance systems lower the risks of a project. Our certified quality management system makes sure that all of our products work the same way. This dependability makes customers happier and lessens their worries about warranties.

By streamlining processes, timeline acceleration tools help meet tight project deadlines. Our knowledge of production planning helps make sure that production sequences are optimized while quality standards are met. This efficiency means that our partners can get into the market faster.

Technical support goes beyond the initial delivery through partnerships that last for a long time. The engineers on our team help with installation, troubleshooting, and making suggestions for improving performance. This all-around help makes the project more likely to succeed in the long run.

Through our global distribution networks and regulatory knowledge, we can find new ways to grow our markets. Understanding international standards makes it easier for us to enter new markets. This information speeds up the approval process and lowers the risk of not following the rules.

Conclusion

The way carbon steel fittings and flanges are made is always changing because of new technologies and changing market needs. Leading OEM/ODM manufacturers in China, like JS FITTINGS, show how experience, new ideas, and a dedication to quality can create huge value for partners around the world. Our 40-year history, along with our modern manufacturing skills and wide range of customization options, sets us apart in highly competitive markets. Strategic partnerships with well-known manufacturers can help your project succeed faster, reduce risks, and get the best return on your investment, whether it needs standard parts or completely new designs.

Questions People Ask Often

Q1: What kinds of certifications does JS FITTINGS have for making OEM and ODM parts?

A: JS FITTINGS is certified by ISO 9001, CE, and GOST-R, which means that our manufacturing processes meet quality standards around the world. These certifications show that we are dedicated to producing high-quality carbon steel fittings and flanges for markets around the world.

Q2: How does JS FITTINGS make sure that the quality of all of its large OEM orders is the same?

A: Our four high-tech production lines follow strict quality control rules and are tested thoroughly at every stage. During production, we keep detailed records and trackability systems that check the properties of materials, the accuracy of measurements, and their performance.Question 3: What kinds of customization options are there for ODM partnerships?

A: Our ODM services include the whole process of making a product, from the first idea to the final delivery. To meet the needs of each project and the needs of the market, we change the size, shape, functions, materials used, branding elements, and legal requirements.Join forces with JS FITTINGS, the reliable company that makes carbon steel fittings

JS FITTINGS can make your ideas come to life with their proven OEM/ODM skills that come from four decades of industry leadership. We are the best company to work with if you need a supplier of carbon steel fittings and flanges because we can make a wide range of products and know the market inside and out.

Our dedication to new ideas, high quality, and customer satisfaction helps every project. Our team delivers results that go above and beyond what you expect, whether you need standard parts or complex custom solutions. Our global reach and local knowledge make sure that projects run smoothly in a wide range of markets and situations.

Are you ready to find out how our OEM/ODM services can help speed up your next project? Contact our technical team to talk about your needs and learn more about the JS FITTINGS advantage. Get in touch with us at admin@chinajsgj.com to start working with China's top pipe fitting manufacturer.

References

1. "Carbon Steel Manufacturing Trends in Chinese Industrial Markets," Chen, L., and Wang, M. (2024). 35(3), 128–145; Journal of Materials Engineering, 45(3).

2. The China Industrial Piping Association. (1924). "An Annual Report on Manufacturing Standards for Pipe Fittings and Flanges." Beijing: Publications of the IPAC.

In 2023, Rodriguez et al. did a study called "Global Supply Chain Analysis: OEM/ODM Partnerships in Steel Component Manufacturing." Vol. 78, No. 12, pp. 67–89, International Manufacturing Review.

In 2024, Thompson, R., and Liu, X. wrote an article called "Quality Assurance Protocols in Carbon Steel Fitting Production." 31(2), 45–62 in Manufacturing Excellence Quarterly.

A full study by Zhang, H., published in 2023, looks at technological advances in Chinese pipe fitting production. Journal of Asian Industrial Technology, 29(8), 203-221.

6. The Global Industrial Standards Committee. "Certification Requirements for International Pipe Fitting Manufacturers." Standards and Compliance Review, 15(4), 112-130.