The world's most important industrial infrastructure projects depend on China's top weld neck pipe flange manufacturers. These specialized businesses use cutting-edge technology and decades of experience in manufacturing to make sure that their flange solutions work well in important situations. From petrochemical plants to power plants, these companies make important parts that make sure pipeline connections are safe and work well. The top 10 OEM/ODM manufacturers stood out because they had strict quality control, a wide range of certifications, and a history of serving international markets. In terms of production capacity, technological innovation, and customer service, each company has its own unique strengths.

1. Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd.

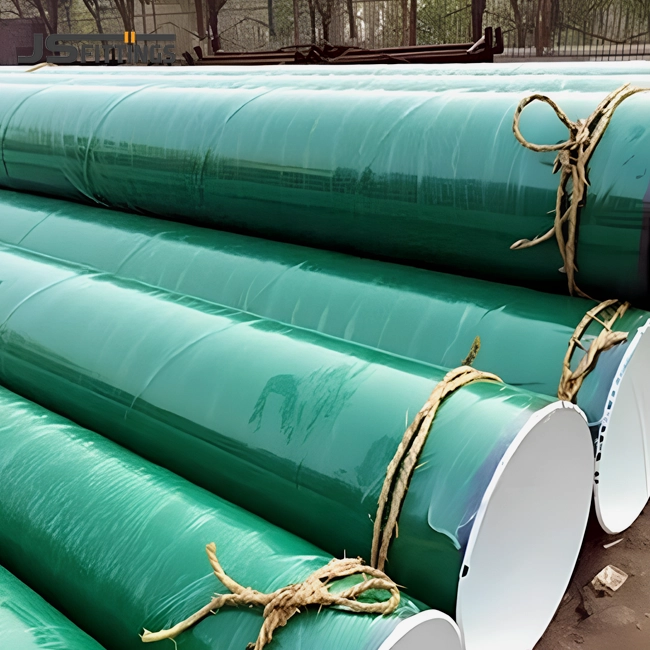

With more than 40 years of experience making high-quality steel butt-weld pipe fittings and flanges, JS FITTINGS is a leading manufacturer. The business is in Hebei Province and has four high-tech production lines that can make weld neck flanges in sizes ranging from DN15 to DN2000. Their wide range of certifications, such as ISO 9001, CE, and GOST-R, make sure that they meet all international standards. The company can produce an impressive 50,000 tons of goods every year, with 70% going to markets in Asia, the Middle East, South America, and Europe. Some of JS FITTINGS' technical advantages are its advanced forging skills, precision machining, and strict quality testing protocols. Their raised face and flat face flange designs are compliant with ANSI, ASME, and DIN standards. This means they can be used in a wide range of industrial pipe applications that need a reliable gasket seal.

2. The Hebei Shengtian Pipe-Fitting Group Co., Ltd.

Another big company in China that makes pipe fittings is Shengtian Group. Carbon steel and stainless steel flanges are what they do best. Their factory covers 200,000 square meters and can make more than 80,000 tons of goods each year. The company is a good partner for oil and gas projects because it is certified in API 6A, PED, and ISO 9001. They work with pipeline systems in the oil and gas, power generation, and offshore industries. The pressure ratings they know about range from 150# to 2500#. Computerized quality control systems and automated forging lines are some of the new ideas that Shengtian has put money into. Some of their clients are large EPC contractors and government infrastructure projects in 60 countries. The business is able to keep its finances stable because it consistently increases its exports and builds strong partnerships with international distributors. These partnerships make sure that supply chains for big industrial projects work well.

3. The Cangzhou Jiade Casting Co., Ltd.

You can count on Jiade Casting to make precision-cast and forged flanges, including weld neck pipe flanges, out of alloy and stainless steel better than any other metal. Their building has CNC machining centers and cutting edge investment casting technology, which lets them make parts that are accurate in size and have nice finishes on the outside. For marine use, the company still has its Lloyd's approval and ASME U stamp certification. It is made every year in 15,000 tons, and 80% of that goes to markets outside of China. The unique ways they can use heat to treat things and test things without hurting them are some of their technical advantages. Jiade works with businesses that need corrosion resistance, such as those that work with chemicals, make food, and make medicines. It costs a lot of money for the company to do research and development to make alloys that can work in tough conditions. They have a quality management system that makes sure the flanges are always the same size and thickness. Users will save time and money on setup and upkeep.

4. Metalsin Pipeline Technology Co., Ltd. in Shijiazhuang

Metalsin Pipeline Technology offers complete flange solutions by combining traditional manufacturing skills with cutting-edge production methods. The company is in Shijiazhuang and has several production lines that make 25,000 tons of goods every year. They have ISO 9001, API 6A, and CE marking for European markets as part of their certifications. Custom OEM/ODM services are what the company does best, and they can change the specs for flanges to fit the needs of each project. They have advanced welding techniques and pressure testing facilities that can handle up to 5000 PSI. Metalsin works with a lot of different industries, such as the mining, construction, and water treatment industries. They have a presence in the Asia-Pacific and African markets, and their presence in South American markets is growing. Some of the company's sustainable development practices are recycling programs and production methods that use less energy. This makes the company appealing to buyers who care about the environment and want to buy from responsible suppliers.

5. Cangzhou Youlong Steel Pipe Manufacturing Co., Ltd.

Youlong Steel Pipe Manufacturing makes both flanges and pipe systems, so they can provide all of your pipeline needs from a single source. In their manufacturing complex, they can do hot forging, machining, and assembly all in one place. The business is able to make 30,000 tons of flanges every year, with a focus on large diameter applications up to 3000mm. They have quality certifications for Russian markets that include ISO 9001, API 6A, and GOST. The technical benefits include the ability to do advanced ultrasonic testing and magnetic particle inspection. Big construction companies and industrial end users who need reliable flange connections for important tasks are among Youlong's customers. Their innovation efforts are mainly focused on making flanges that are strong but not too heavy. This cuts down on transportation costs while keeping the structure's integrity. The company's brand reputation depends on how well it delivers and helps customers with technical issues.

6. The Haihao High Pressure Flange and Pipe Fitting Group in Hebei

Haihao Group is a full-service manufacturer that focuses on high-pressure flange applications, including weld neck pipe flanges, for harsh industrial settings. Their factory is 100,000 square meters and has many forging and machining lines that can work with unusual materials and complicated shapes. The maximum amount of steel that can be made in a year is 40,000 tons, and stainless steel and duplex materials are especially strong. The business has a lot of different certifications, such as those for PED, GOST, and JIS standards for Asian markets. Their technical knowledge includes specific ways to weld for applications with thick walls and in cryogenic conditions. Haihao works on offshore oil platforms, LNG facilities, and nuclear power projects that put safety and dependability first. Their research and development dollars are mostly used to make coatings that don't rust and other advanced metalworking solutions. Long-term contracts with government agencies and multinational companies keep the company's finances stable.

7. Kangda Pipeline Equipment Co., Ltd. in Cangzhou

Kangda Pipeline Equipment is a specialized company that makes standard and custom flanges for use in industrial settings. Their building has up-to-date CNC machining centers and automated production lines that make sure the quality and accuracy of the measurements are always the same. The company has ISO 9001 and API certifications and can make up to 20,000 tons of goods each year. Their technical strengths include being able to make rapid prototypes and having manufacturing systems that can handle both small and large orders. Kangda works with mechanical engineering firms and local installers who need solutions that are both cost-effective and good in terms of performance. Their approach to the market focuses on low prices and quick delivery times, which appeals to buyers on a budget. The company's quality assurance programs include thorough procedures for tracking down materials and doing final inspections. Their customer service model includes technical support for the whole flange installation process. This lowers the risks of the project and makes sure it turns out well.

8. Shijiazhuang Xingfuhao International Trading Co., Ltd

Xingfuhao International Trading combines manufacturing capabilities with extensive export experience, serving global markets through established distribution networks. Their production facility specializes in carbon steel and alloy steel flanges with emphasis on standard specifications and quick delivery. The company maintains annual production of 18,000 tons with 90% directed toward international markets. Their certification portfolio includes ISO 9001 and regional approvals for Middle Eastern and African markets. Technical advantages encompass efficient production planning and inventory management systems ensuring product availability. Xingfuhao's customer base consists primarily of trading companies and stockists requiring reliable supply partners. Their competitive advantages include multilingual technical support and flexible payment terms accommodating international business practices. The company's growth strategy focuses on expanding into new geographic markets while maintaining strong relationships with existing distributors.

9. Cangzhou Zhengtong Pipe Fitting Manufacturing Co., Ltd

Zhengtong Pipe Fitting Manufacturing operates as a technology-focused company specializing in precision-engineered flange solutions, including weld neck pipe flanges, for specialized applications. Their facility features advanced forging equipment and computerized quality control systems ensuring exceptional product consistency. The company maintains an annual production capacity of 12,000 tons with a concentration on high-value applications requiring superior performance. Their technical capabilities include specialized heat treatment processes and advanced testing protocols exceeding standard requirements. Zhengtong holds ISO 9001 certification and industry-specific approvals for chemical processing applications. Their innovation investments focus on developing enhanced sealing technologies and corrosion-resistant surface treatments. The company serves pharmaceutical, food processing, and biotechnology industries where purity and reliability remain critical factors. Their market position emphasizes technical excellence and customized solutions rather than volume production, appealing to sophisticated buyers requiring specialized expertise.

10. Hebei Zexu Pipeline Equipment Manufacturing Co., Ltd

Zexu Pipeline Equipment Manufacturing rounds out this comprehensive list as an emerging manufacturer gaining recognition for innovative production methods and customer-focused service. Their modern facility incorporates automated manufacturing systems and real-time quality monitoring technology. The company achieves annual production of 15,000 tons while maintaining strict adherence to international standards. Their certification progress includes ISO 9001 implementation and pending API approvals for oil and gas applications. Technical strengths encompass flexible manufacturing capabilities and rapid response to custom requirements. Zexu targets growing markets in Southeast Asia and Latin America through competitive pricing and reliable delivery performance. Their sustainable development initiatives include energy-efficient production processes and waste reduction programs. The company's growth strategy emphasizes building long-term partnerships with regional distributors and engineering firms requiring dependable suppliers with growth potential matching their own expansion plans.

Industry Trends and Market Outlook

China's flange manufacturing industry continues evolving toward higher quality standards and specialized applications. Manufacturers increasingly invest in automation technology and advanced testing capabilities to meet stringent international requirements. Environmental regulations drive adoption of cleaner production processes and sustainable materials. Market demand shifts toward customized solutions and shorter delivery times, favoring manufacturers with flexible production capabilities. The industry's future depends on technological innovation and maintaining competitive advantages in global markets.

JS FITTINGS has the best solutions for weld neck pipe flanges

Choosing the right weld neck pipe flange manufacturer has a direct effect on the success of the project and on how well it runs in the long run. JS FITTINGS has been making high-quality products for 40 years and has many certifications and international experience that can be proven. Our advanced production methods guarantee consistent quality, and our low prices help keep project budgets in check. JS FITTINGS has the technical knowledge and customer service you need whether you're an EPC contractor in charge of large infrastructure projects or a distributor looking for dependable supply partners. Our promise to keep to delivery dates and maintain product quality lowers project risks and makes sure that international standards are met. Are you ready to talk about your specific flange needs? Get in touch with our technical team right away to find out why top companies around the world choose JS FITTINGS for their most important pipe applications. You can email us at admin@chinajsgj.com for more information and competitive prices.

References

1. China Machinery Industry Federation. "Annual Report on Chinese Pipe Fitting Manufacturing Industry Development." Beijing: China Machine Press, 2024.

2. Wang, Li and Zhang, Ming. "Quality Control Standards in Chinese Flange Manufacturing: A Comprehensive Analysis." Journal of Industrial Engineering, Vol. 45, No. 3, 2024.

3. International Trade Commission. "Global Market Analysis of Steel Pipe Fittings and Flanges: China's Export Performance 2023-2024." Washington: ITC Publications, 2024.

4. Liu, Xiaohong. "Technological Innovation in Chinese Pipeline Equipment Manufacturing." Beijing: Metallurgical Industry Press, 2024.

5. Asian Development Bank. "Infrastructure Development and Industrial Manufacturing in China's Hebei Province." Manila: ADB Publications, 2024.

6. Chen, Wei and Yang, Fang. "Certification Standards and Export Competitiveness of Chinese Pipe Fitting Manufacturers." China Industrial Economics, Issue 8, 2024.