- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

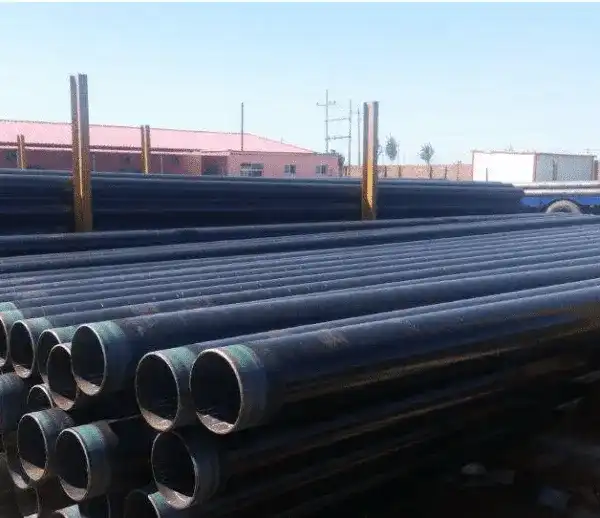

Why Pipeline Companies Choose China A53 Seamless Pipes?

Because they are so reliable, cost-effective, and consistent in quality, pipeline companies around the world are increasingly using China's A53 seamless pipes for tough industrial uses. The A53 seamless pipe made in China uses better manufacturing methods to get better structural integrity, which makes it perfect for high-pressure systems in building, infrastructure, and oil and gas projects. Chinese manufacturers have built up strong production capabilities with a wide range of certifications. This allows them to meet tough foreign standards while keeping their prices low, which is attractive to procurement teams overseeing large-scale pipeline projects.

Understanding China A53 Seamless Pipes: Specifications and Advantages

China's seamless steel pipe business has changed a lot and now makes products that comply with ASTM A53 and strict international standards. They make these pipes without soldered seams, so the structure is the same all the way through and works better under pressure.

Manufacturing Excellence and Quality Standards

By using hot rolling and piercing methods, Chinese producers make seamless pipes out of steel that don't have the weak spots that welded pipes do. In the production process, solid steel billets are heated to about 1,200°C and made into hollow shapes by piercing them with specialized tools called "mandrels." This method makes sure that the wall thickness and strength are uniform all along the length of the pipe.

Top Chinese makers use chemical composition analysis, mechanical property testing, and hydrostatic pressure testing as part of their quality control. These detailed testing methods ensure that every pipe meets the ASTM A53 Grade A and Grade B standards. Grade B is especially well-liked for its extra strength, which makes it a good fit for medium- to high-pressure uses.

Technical Specifications and Performance Characteristics

Chinese A53 seamless pipes usually have 0.25% to 0.30% carbon, 0.95% to 1.20% manganese, and small amounts of sulfur and phosphorus that are kept under control to make sure the pipes can be welded easily and prevent corrosion. These standards give the pipes a tensile strength of 48,000 to 70,000 psi, which makes them good for a range of industrial pipeline uses.

These pipes' mechanical properties show that they work very well in tough circumstances. For Grade A, the yield strength is usually between 30,000 and 35,000 psi, and for Grade B, it is up to 35,000 psi. The yield strength also has elongation qualities that make sure the material is flexible when it's put in place and used. Because of these traits, Chinese A53 seamless pipes are especially useful for projects that need to be able to count on them to work well even when the pressure changes.

Why Pipeline Companies Prefer China A53 Seamless Pipes: Decision-Making Insights?

The benefits of getting goods from Chinese makers go beyond just the cost. These benefits include reliable supply chains, technical expertise, and full service that can help with complicated project needs.

Cost-Performance Optimization

Chinese makers have really good prices because they use economies of scale and efficient production methods. The 30,000-ton production capacity guarantee from well-known suppliers like JS FITTINGS means that supply chains can meet the needs of big projects without delaying deliveries. This level of production means that each item can be sold at a low price, and the quality can be kept high for important transit uses.

When you buy a lot from Chinese suppliers, they often offer good payment terms and volume discounts that have a big effect on the cost of doing a job. These plans help procurement teams make the best use of their budgets and make sure they have solid sources for materials for longer project timelines.

Certification Excellence and Compliance Assurance

Top Chinese pipe makers keep approved steel pipes with API 5L and EN 10219 dual compliance. This shows that they are dedicated to meeting a range of global standards. These certificates give procurement teams across a range of markets and uses extra trust in the quality of materials and compliance with the law.

ISO 9001 quality management systems, CE marking for European markets, and a range of national standards compliance certificates are usually found in the certification collection. This broad certification method makes it easier for buying teams to work on international projects that have to follow different rules.

Advanced Service Capabilities

Chinese pipe makers have built advanced service options that go beyond just supplying pipes. Ready-to-use pipe end solutions from precision cutting services lower the time needed for on-site preparation and make sure of the correct fit-up during installation. These extra services help the project get done faster and more cheaply.

The oil and gas project logistics system created by seasoned Chinese providers has special shipping options for the Central Asia and Middle East markets. These specialized logistics skills make sure that products are delivered on time to project sites far away, and they keep the quality of the product while in transit.

Comparison: China A53 Seamless Pipes vs. Other Pipe Types

Knowing how different kinds of pipes work and how much they cost makes it possible to choose pipe materials wisely based on the needs and conditions of each job.

A53 vs A106 Seamless Pipe Analysis

The A53 and A106 seamless pipes differ mainly in the uses they are designed for and their temperature and pressure ratings. A106 pipes are made for high-temperature and high-pressure settings where they need to always work well, while A53 pipes are made for settings with low to medium temperature and pressure.

The chemical makeup of these specifications is very different, and both materials have similar mechanical qualities when they are used normally. A106 pipes, on the other hand, are made and tested with more strict quality rules, which raises the cost of the materials. A53 seamless pipes give the best mix of cost and performance for normal pipeline uses where extreme conditions aren't expected. They also keep the safety margins that are needed.

Corrosion Resistance and Environmental Suitability

A53 seamless pipes show great resistance to rust, especially when galvanized coatings are used to protect the environment even more. This ability to fight corrosion is very useful when pipes are outside or in water, where they can get wet and come into contact with chemicals and other things that can break them down.

Carbon steel A53 pipes are much cheaper than stainless steel options like grade 304, and they also prevent corrosion well enough for most industrial uses. The difference in cost can be big in large projects. This allows the budget to be optimized without losing the dependability of the project.

Pressure Rating and Structural Integrity

A53 seamless pipes' pressure testing powers meet the needs of tough industries, and their suitability for high-pressure fluid transport systems is confirmed by hydrostatic testing. These pipes hold pressure very well under normal working situations, and they don't break down over time.

The seamless construction gets rid of possible failure spots at welded joints, making it more reliable for important pipeline uses. This benefit of structure is especially useful in situations where vibration, thermal cycle, or changing pressure could stress the welds.

Procurement Guide: How to Source China A53 Seamless Pipes

If you want to successfully buy Chinese seamless pipes, you need to know about the suppliers, the market, and the processes that affect the project and the overall cost.

Supplier Selection and Qualification

It is important to look at a supplier's manufacturing skills, quality certifications, and experience exporting to the target markets when deciding if they are qualified. For complicated pipeline projects, established manufacturers with a history of success in international projects are more reliable and can give more technical support.

Facility surveys, quality system reviews, and reference checks from similar projects should all be a part of supplier qualification. These tests help find partners who can meet certain technical needs and shipping times while keeping quality high during the whole supply relationship.

Ordering Processes and Customization Options

Chinese manufacturers provide a range of ordering choices that can be tailored to both standard and unique needs. Direct factory buying usually offers better prices and technical support than distributor arrangements. It also helps people work together more closely on changing specifications and planning deliveries.

Customization can change dimensions, add special ends, or raise testing standards beyond the norm. These choices let procurement teams get the best material specs for certain uses while keeping costs down through smart sourcing partnerships.

Logistics and Delivery Considerations

When sending seamless pipes internationally, they need to be handled in a certain way, and specific paperwork is needed. These steps are handled well by experienced Chinese suppliers. It usually takes 4 to 8 weeks to deliver an order, based on how complicated the specifications are and how many items are ordered. For projects that need to be done right away, there are faster delivery options.

Shipping plans should look at how many ports can handle the cargo, how it will get to the final location, and which customs rules apply to each country. Logistics help, like making sure documents are in order, coordinating shipping, and tracking deliveries across the whole supply chain is done by experienced suppliers.

JS FITTINGS: Your Trusted China A53 Seamless Pipe Supplier

Hebei Jinsheng Pipe Fitting Manufacturing Co., Ltd (JS FITTINGS) represents over 40 years of manufacturing excellence in high-quality steel pipe products serving global industrial markets. Our wide range of products includes seamless pipes, pipe fittings, and flanges made to global standards. Our products have been certified by ISO 9001, CE, and GOST-R.

Production Capabilities and Quality Assurance

We can support the supply chains of big projects across the Middle East, South America, Europe, and Asia because we can make 30,000 tons every year. Advanced production lines use modern manufacturing technologies that make sure the quality of the products is uniform and keep competitive delivery times for projects that need to be done quickly.

Chemical analysis, mechanical testing, and dimensional verification are all parts of quality control methods that make sure ASTM A53 seamless pipes standards are met. Our two-standard certification method makes sure that you follow both API 5L and EN 10219. This makes it easy to use in a variety of foreign projects that need to follow different sets of rules.

Value-Added Services and Technical Support

Precision cutting services provide pipe end treatments that are ready to use. These make the fitting quicker and make sure that the fit-up is correct during field assembly. These value-added features help the project get done faster while keeping the structure in good shape so that the process works properly.

Our specialized oil and gas project transportation system offers unique shipping options for the Central Asian and Middle Eastern markets. This all-around shipping system makes sure that products are delivered on time to project sites far away while keeping the quality of the products during the trip.

Conclusion

Pipeline businesses looking for reliable, affordable options for tough industrial uses have come to favor China A53 seamless pipes. Chinese suppliers are strategic partners for global procurement teams managing complicated pipeline projects because of their advanced manufacturing, low prices, and wide range of services. If you choose the right suppliers and make sure quality standards are met, these pipes will give you great value and meet strict performance standards in a wide range of industries.

FAQs

Q1: What industries commonly use A53 seamless pipes?

A53 seamless pipes serve multiple industries, including oil and gas pipeline construction, water treatment facilities, HVAC systems, and structural applications. These pipes are particularly valuable in applications requiring medium-pressure fluid transport with reliable long-term performance characteristics.

Q2: How can buyers verify the quality of Chinese A53 seamless pipes?

Quality verification involves reviewing manufacturer certifications, conducting third-party inspections, and requesting material test certificates for each shipment. Reputable suppliers provide comprehensive documentation, including chemical analysis reports, mechanical property test results, and hydrostatic pressure test certificates.

Q3: Are custom sizes available for A53 seamless pipes from Chinese manufacturers?

Chinese manufacturers offer extensive customization options, including non-standard dimensions, special end preparations, and enhanced testing requirements. Custom orders typically require longer lead times but enable optimization for specific application requirements while maintaining cost-effectiveness.

Q4: What are typical delivery lead times for Chinese A53 seamless pipe orders?

Standard delivery lead times range from 4-8 weeks, depending on order complexity and quantity requirements. Expedited delivery options are available for urgent projects, while large-scale orders may require extended lead times to ensure adequate production scheduling and quality control.

Partner with JS FITTINGS for Your A53 Seamless Pipe Requirements

JS FITTINGS stands ready to support your pipeline projects with high-quality A53 seamless pipe solutions backed by four decades of manufacturing expertise. As a leading A53 seamless pipe manufacturer, we offer competitive pricing, reliable delivery schedules, and comprehensive technical support for projects worldwide. Our team provides personalized consultation services to optimize material selection and logistics arrangements for your specific requirements. Contact us at admin@chinajsgj.com or visit chinajsgj.com to discuss your project needs and discover how our proven capabilities can enhance your procurement success.

References

1. American Society for Testing and Materials. "ASTM A53/A53M Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless." ASTM International, 2020.

2. Zhang, Wei, and Liu Chen. "Quality Control and Manufacturing Processes in Chinese Steel Pipe Industry." International Journal of Steel Manufacturing, Vol. 15, No. 3, 2023.

3. Global Pipeline Construction Review. "Sourcing Strategies for International Pipeline Projects: A Comprehensive Analysis." Pipeline Engineering Quarterly, 2023.

4. Johnson, Michael, and Sarah Thompson. "Cost-Benefit Analysis of Seamless vs. Welded Pipes in Industrial Applications." Industrial Materials Research, Vol. 28, No. 2, 2023.

5. International Steel Trade Association. "Market Trends and Quality Standards in Asian Steel Pipe Manufacturing." Steel Trade Annual Report, 2023.

6. Roberts, David, et al. "Procurement Best Practices for Large-Scale Infrastructure Projects." Project Management in Heavy Industry, Vol. 12, No. 4, 2023.

Learn about our latest products and discounts through SMS or email