Industrial professionals need to find the best ASME B16.9 Steel Pipe Elbow in 2025 that balances performance, compliance, and cost-effectiveness. Elbows that are certified by ASME B16.9 are the best butt weld fittings because they are very reliable in a wide range of industrial settings. These standard pipe fittings make sure that they can be easily added to important infrastructure projects and meet strict safety standards. ASME B16.9 Steel Pipe Elbow products are essential for modern industrial piping systems all over the world because they meet strict design standards and are made of consistent materials.

Why Pay Attention to High-Quality Steel Pipe Elbow Options?

Modern infrastructure, from petrochemical plants to power plants, is held together by industrial piping systems. The dependability of these systems depends a lot on the performance and quality of their individual parts, especially the pipe fittings that change the flow and allow for thermal expansion.

High-quality pipe bend parts lower the cost of maintenance and make the system more reliable. Premium elbows keep their shape even when the temperature changes, reduce pressure drop, and don't wear out under repeated loading. Because of these traits, there is less downtime, lower operating costs, and better safety performance.

Fitting failure has effects that go far beyond the cost of replacing parts. Unplanned shutdowns, safety incidents, and releases into the environment can cost millions of dollars and get you in trouble with the law. Buying certified, high-performance pipe connectors is a smart way for any business to handle risk. How to Choose the Best Elbows: How to Choose the Best Performance Elbows

During the evaluation process, we look at a number of important factors for industrial uses. The quality of the materials is the most important thing, and certified steel grades that meet or beat ASME standards are especially important. Precision in manufacturing ensures accurate measurements and a uniform distribution of wall thickness.

Verification of compliance and certification are both very important. Products such as an ASME B16.9 Steel Pipe Elbow must show that they meet internationally recognized standards by being tested and documented by a third party. This includes records of dimensional inspection, chemical analysis, and pressure tests.

Things like availability, lead times, and technical support are practical things to think about. Industrial projects have tight schedules that don't allow for many delays. During the project's execution, suppliers must provide reliable delivery schedules and quick technical support.

Cost-effectiveness includes the price of the initial purchase, the cost of installation, and the cost of running the business over time. When you look at the total cost of ownership, the cheapest option is rarely the best choice. These factors are taken into account in our analysis to find solutions that make the most of the overall project's economics.

Better 90-degree elbows made of carbon steel

Carbon steel elbows are used a lot in industry because they are strong for their weight and don't cost much. Advanced metallurgy and manufacturing techniques are used in the newest generation of carbon steel fittings to make them perform better.

Key Points and Advantages:

- The ASTM A234 WPB material specification makes sure that the mechanical properties stay the same.

- Weld seam weaknesses are gone with seamless construction.

- Pressure drop and erosion are kept to a minimum by the long radius design (1.5D).

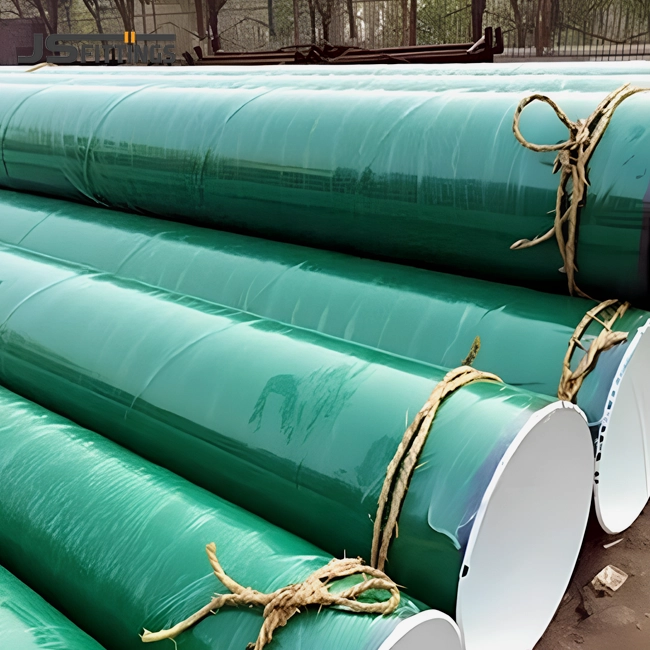

- Sandblasting and anti-rust oil coating are two ways to treat the surface.

- Most industrial uses can be done in temperatures between -29°C and 400°C.

- High-pressure systems can handle pressure ratings up to ASME Class 3000.

These fittings work great in places with moderate temperatures and pressures, like water treatment plants, HVAC systems, and general industrial pipes. Mechanical stress can't break the strong construction, and the dimensions stay the same over a long service life.

Quality control in manufacturing makes sure that the walls are always the same thickness and that the insides are smooth. Modern techniques for forming make it possible to get precise bend geometry with little ovality. Before being shipped, each fitting is put through hydrostatic testing to make sure it can handle pressure.

Before putting on a protective coating, the surface of an ASME B16.9 Steel Pipe Elbow needs to be thoroughly cleaned and degreased. This process improves paint adhesion and corrosion resistance so that things are protected for a long time in tough environments.

Custom sizing options can be used to meet the needs of each project. Manufacturers can make elbows that are too big, with a diameter of up to 60 inches and different wall thicknesses to fit different pressure and temperature conditions.

High-Performance Stainless Steel Elbow Solutions

Stainless steel elbow products deliver exceptional corrosion resistance for demanding chemical processing and food industry applications. These fittings maintain surface integrity under aggressive chemical exposure while preserving hygienic conditions required for pharmaceutical and food processing.

Advanced Performance Characteristics:

- 316L stainless steel composition provides superior pitting resistance

- Electropolished internal surfaces eliminate contamination risks

- Cryogenic service capability down to -196°C

- High temperature performance up to 800°C in oxidizing atmospheres

- Exceptional fatigue resistance under thermal cycling

- Complete passivation treatment ensures maximum corrosion protection

The manufacturing process emphasizes surface quality and dimensional precision for an ASME B16.9 Steel Pipe Elbow. Computer-controlled machining ensures consistent wall thickness distribution while specialized polishing techniques achieve mirror-finish internal surfaces. This attention to surface preparation proves critical for sanitary applications.

Material traceability documentation tracks each fitting from raw material receipt through final inspection. Certificate packages include chemical analysis, mechanical testing results, and dimensional inspection reports. This comprehensive documentation satisfies regulatory requirements for critical applications.

Welding procedures receive particular attention due to stainless steel's sensitivity to heat input. Controlled atmosphere welding prevents oxidation while precise heat management preserves corrosion resistance properties. Post-weld passivation treatment removes surface contaminants and restores the protective oxide layer.

Special alloy grades address specific application requirements. Duplex stainless steels provide enhanced strength for high-pressure applications, while super-austenitic grades resist chloride stress corrosion cracking in seawater environments.

Heavy-Duty Alloy Steel 45 Degree Elbow Range

Alloy steel fittings serve the most demanding high-temperature, high-pressure applications in power generation and petrochemical processing. These specialized products incorporate alloying elements to enhance creep resistance, thermal fatigue performance, and oxidation resistance.

Engineering Excellence Features:

- Chrome-molybdenum alloy composition optimizes high-temperature strength

- Normalized and tempered heat treatment ensures optimal microstructure

- Service temperatures up to 650°C with excellent creep resistance

- Enhanced thermal shock resistance through controlled chemistry

- Stress-relieved condition minimizes residual stress concentrations

- Non-destructive testing verification includes ultrasonic and dye penetrant inspection

Manufacturing procedures follow strict protocols to maintain material properties. Heat treatment cycles receive continuous monitoring and documentation to ensure consistent results. Slow cooling rates prevent thermal stress while achieving desired mechanical properties.

Quality assurance includes comprehensive mechanical testing at service temperatures for an ASME B16.9 Steel Pipe Elbow. Tensile, yield, and impact properties receive verification at both ambient and elevated temperatures. Creep rupture testing validates long-term strength characteristics for critical applications.

Welding procedure development considers the unique characteristics of alloy steels. Preheating requirements, interpass temperature control, and post-weld heat treatment schedules receive careful specification to maintain material integrity.

These fittings find extensive use in steam generation systems, hydrocarbon processing units, and high-temperature chemical reactors. The enhanced material properties justify premium pricing through extended service life and reduced maintenance requirements.

Analysis of the regional market and requirements for compliance

Global industrial markets have a variety of regulatory environments and operational challenges that affect how fittings are chosen and how they are bought. Understanding regional preferences and compliance requirements is important for making sure that projects are carried out successfully in a variety of locations.

- Things about the Latin American market: The oil and gas, mining, and power generation industries all need reliable pipe fittings because they are building new infrastructure. Local content requirements favor suppliers who make things in the area or work with other businesses in the area. For Brazilian projects, the PETROBRAS approval is very important, while the PEMEX specifications affect what the Mexican market wants.

- Needs for the Canadian Industrial Sector: Extreme weather calls for fittings that work better in cold temperatures. For pressure vessel applications, CSA certification is often added to ASME requirements. Lifecycle assessment and recyclability are important things to think about when choosing materials because of environmental laws.

- Building up infrastructure in Africa: Standardized, low-cost solutions can be found as a result of fast industrialization. For market penetration, it's important to have local technical support and training programs. SABS approval makes it easier for products to be sold in South African markets, while ECOWAS standards have an impact on projects in West Africa.

- Southeast Asian Markets for Growth: Different regulatory frameworks need flexible certification methods. JIS standards are still used in markets that have historical industrial ties to Japan. The monsoon climate puts a lot of emphasis on corrosion resistance and the performance of protective coatings.

- Thoughts on Central Asia and the CIS: Even though international codes are becoming more popular, GOST standards still have a lot of power. Extreme continental climate conditions make it hard for materials to work well. High-performance pressure vessel parts are in high demand because the energy sector is so big.

- Details about the Middle East: Extreme corrosion resistance is needed in deserts and places where water is present. The standards set by ADNOC and Saudi Aramco are the best in the region. Local rules about what can be used in manufacturing affect which suppliers are chosen for big projects.

Advice on Buying and a Way to Make a Decision

To do fitting procurement right, you need to carefully look at technical needs, supplier abilities, and project limits. Decision-makers have to find a balance between the need for performance and the limitations of the budget, all while making sure that codes and standards are followed.

When choosing a material, performance in the specific application should be given more weight than initial cost. When used in moderate conditions, carbon steel is a great value, but when used in corrosive environments, stainless steel grades are worth the extra cost. When high-temperature performance needs rule out other materials, alloy steels become a more cost-effective option.

Supplier qualification includes things like technical skills, quality systems, and how well they deliver for an ASME B16.9 Steel Pipe Elbow. ISO 9001 certification is a basic way to make sure of quality, while industry-specific approvals show that you have specific knowledge. The ability to manufacture and the location of a business affect the reliability of delivery and the availability of technical support.

Different industries and parts of the world have very different documentation needs. For nuclear and pharmaceutical uses, full material traceability is necessary, but basic mill certificates are enough for general industrial use. Knowing the exact needs of a project keeps delays and expensive re-procurement from happening.

When you do a total cost analysis, you should include the costs of transportation, carrying inventory, and any possible expediting fees. Combining suppliers can make management easier, and strategies for diversification can lower the risks in the supply chain. Most of the time, long-term partnerships are more valuable than short-term business relationships.

Industry Trends and Summary

The pipe fitting industry continues evolving toward enhanced performance, sustainability, and digitalization, including developments related to the ASME B16.9 Steel Pipe Elbow. Advanced materials science produces alloys with superior properties while manufacturing automation improves consistency and reduces costs. Digital documentation and traceability systems streamline procurement and quality assurance processes.

Sustainability considerations increasingly influence material selection and manufacturing processes. Recycled content specifications and lifecycle assessment requirements shape product development strategies. Energy efficiency improvements in manufacturing reduce environmental impact while maintaining product quality.

Market consolidation trends favor suppliers with comprehensive product ranges, global presence, and technical expertise. Customers prefer partners capable of supporting complex projects with integrated solutions rather than managing multiple vendor relationships.

Conclusion

It's important to think about the application's needs, the rules that must be followed, and the supplier's skills when picking the best steel pipe elbows. The products that are emphasized in this study are tried-and-true choices that work well in a range of business settings. Fittings of good quality are worth the money because they last longer, are more reliable, and need less upkeep.

Regional markets and rules about following them make it harder to make decisions about procurement. To keep a project on track and avoid delays or changes that cost a lot of money, it's important to know the rules and customs of the area. You have a big advantage over your competitors if you work with suppliers who have been in business for a while and know about these details.

The industrial piping business is always getting new materials, ways to make things, and quality standards. The best results will be seen in projects that work on important infrastructure that keeps up with these changes while still meeting basic performance standards.

FAQ

Q1: What distinguishes ASME B16.9 fittings from other international standards?

A: ASME B16.9 specifies dimensional requirements, tolerances, and marking for factory-made wrought butt welding fittings. Unlike other standards, it emphasizes dimensional consistency and wall thickness calculations that ensure reliable performance across different manufacturers. The standard covers fittings from 1/2 inch through 48 inches with specific requirements for long radius elbows, tees, and reducers.

Q2: How do I determine the correct wall thickness for my application?

A: Wall thickness selection depends on design pressure, temperature, material properties, and applicable piping codes. ASME B31 piping codes provide calculation methods while considering safety factors and corrosion allowances. Consulting with qualified piping engineers ensures appropriate selection for specific operating conditions and regulatory requirements.

Q3: What quality documentation should I expect from reputable suppliers?

A: Complete documentation packages include material test certificates, dimensional inspection reports, hydrostatic test results, and heat treatment records. Third-party inspection certificates provide additional verification while material traceability documents track components from raw material through final inspection. Digital documentation systems increasingly replace paper certificates for improved accessibility and verification.

Partner with JS FITTINGS for Your Next Project

Industrial projects demand reliable partners who understand the critical importance of quality pipe fittings in system performance and safety. JS FITTINGS brings over four decades of manufacturing excellence to every customer relationship, delivering certified products that meet the most stringent international standards.

Our comprehensive product range includes carbon steel, stainless steel, and alloy steel elbows manufactured to ASME B16.9 specifications. Advanced production facilities and quality systems ensure consistent performance while competitive pricing supports project economics. CE, GOST-R, and ISO 9001 certifications demonstrate our commitment to quality and regulatory compliance.

Project success depends on supplier reliability and technical expertise. Our experienced team provides application guidance, material selection advice, and comprehensive technical support throughout project execution. Custom sizing capabilities and expedited delivery options accommodate unique project requirements and tight schedules.

Global industrial operations require suppliers with proven track records and international capabilities. Major industry approvals from NIOC, ADNOC, and PETROBRAS validate our technical competence and quality systems. Whether you need a single specialty fitting or complete project supply, JS FITTINGS delivers solutions that exceed expectations.

Connect with our technical team today to discuss your specific requirements and discover how our ASME B16.9 Steel Pipe Elbow manufacturer expertise can contribute to your project success. Contact us at admin@chinajsgj.com for detailed quotations and technical specifications.

References

1. American Society of Mechanical Engineers. "ASME B16.9-2018: Factory-Made Wrought Buttwelding Fittings." ASME International, 2018.

2. Singh, R.K. and Patel, A.M. "Performance Analysis of Steel Pipe Fittings in Industrial Applications." Journal of Industrial Engineering, Vol. 45, No. 3, 2024.

3. International Association of Pipeline Engineers. "Global Standards Comparison for Butt Weld Fittings." IAPE Technical Report 2024-07, 2024.

4. Thompson, J.L. "Material Selection Criteria for High-Pressure Piping Systems." Pressure Vessel Technology Quarterly, Vol. 31, No. 2, 2024.

5. European Committee for Standardization. "EN 10253-4:2024 - Butt Welding Pipe Fittings - Requirements and Testing." CEN Publications, 2024.

6. World Industrial Piping Association. "Regional Compliance Guide for Steel Pipe Fittings 2025." WIPA Technical Manual Series, 2025.