- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Best Blind Flange Manufacturers in China for Oil and Gas Projects

When you need to find trustworthy blind pipe flange providers for important oil and gas infrastructure projects, China is the best place to look. It is a global manufacturing hub that provides great quality, low prices, and a wide range of customization options. Top Chinese producers use cutting-edge production methods and decades of experience to make closing plate flanges that meet tough global standards like those from API, ANSI, and ASME. These builders offer a wide range of services to a variety of customers, including EPC contractors and government building projects. They help make sure that projects are safe, run well, and have as few risks as possible.

Understanding Blind Pipe Flanges in Oil and Gas Applications

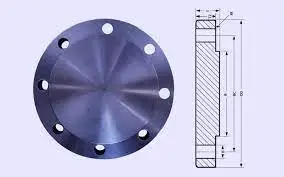

Blind pipe flanges, which are also called closure plate flanges, are very important in petroleum and natural gas pipeline systems where full separation and tight closing are necessary. These specialized fittings have a solid disc design without a center bore. They successfully seal the ends of pipes or the openings of vessels so that fluid cannot flow through them, and the integrity of the system is maintained under extreme conditions.

Core Functionality and Design Characteristics

The basic shape of the closure plate flanges means that flow-through is not possible, but sealing performance is strong. Unlike regular flanges that let fluid pass through them, blind flanges block pipe systems completely. This special thing about them makes them impossible to replace when they are used to isolate a pipeline during routine repair, system testing, or planning for future growth.

The solid build usually uses either a raised face or a flat face design to make sure that the gasket seals better. Industry standards dictate bolt hole patterns. This makes sure that new flanges will fit with the old pipeline parts they connect to and that stress will be evenly spread across the flange face during installation and while in use.

Material Selection for Demanding Environments

Materials that can handle corrosive hydrocarbons, very hot and cold temperatures, and high-pressure situations are needed for oil and gas uses. For normal use, carbon steel blind flanges have a great strength-to-cost ratio, but for places with sour gas that has hydrogen sulfide in it, stainless steel versions are better because they don't rust as easily.

Alloy steels with chromium-molybdenum compositions that improve temperature stability and resistance to creep are also available. These materials meet ASTM standards. They are also tested carefully to make sure that their mechanical properties, chemical makeup, and metallic structure are all sound.

Applications in Pipeline Systems

Blind pipe flanges are used in many different ways in oil and gas infrastructure. They allow the entire duct to be isolated for inspection, cleaning, and repair work without lowering the system's pressure. During construction, these parts create temporary endpoints that make it easier to link new parts later on.

Blind flanges that let testers check the pressure of isolated pipeline sections are helpful for testing purposes. Emergency isolation features are very important for quick system shutdowns. They protect people and the environment from possible hydrocarbon leaks.

Comparison of Blind Flange Types and Materials for Optimal Procurement

Choosing the right blind flange configurations needs a close look at the operational factors, the environmental conditions, and the costs. This in-depth study lets procurement workers name parts that get the best performance while keeping costs low.

Blind Flanges vs. Alternative Flange Types

It's easier to understand the pros and cons of blind flanges when you know how they differ from other flange types. Here are the important differences that affect the choice to buy things:

- Slip-on flanges are easy to install, but can't handle as much pressure as blind flanges. This makes them a bad choice for high-pressure isolation situations where complete sealing is needed.

- Weld neck flanges are better at resisting weakness and breaking over time, but they can't stop the flow completely. This makes them less useful in isolation situations where blind flanges are better.

- While threaded flanges make it easy to put things together quickly without welding, they also create places where leaks can happen. On the other hand, blind flanges get rid of flow pathways completely.

- Wafer flanges save space and weight, but don't seal well enough for uses that need to permanently or semi-permanently end a pipeline

These examples show why blind pipe flanges are still the best option for flow separation in important oil and gas systems.

Material Performance Analysis

There are two main materials for blind flanges: carbon steel and stainless steel. Each has different benefits based on how it will be used. For normal hydrocarbon settings that don't have a lot of corrosive content, carbon steel is a great choice because it has excellent mechanical strength and is cost-effective.

Stainless steel grades, especially 316L, are great at resisting corrosion from chlorides, acids, and hydrogen sulfide, which are widely found in offshore and sour gas applications. The higher upfront cost is often worth it because it lasts longer and needs less upkeep.

Alloy steels are between carbon and stainless steels. They can handle higher and lower temperatures better than those steels and fight rust better too, all for a modestly higher price. These materials are especially useful in applications with high temperatures where carbon steel gets close to its limits as a metal.

Manufacturing Standards and Quality Assurance

Compliance with international standards in terms of dimensional accuracy makes sure that the global flow system works with the parts that are used. ASME B16.5 tells you the pressure ratings, dimensions, and materials for normal blind flanges. API 6A standards are used for wellhead and production equipment.

The way something is made has a big effect on the quality and performance of the finished product. If you need a simple shape, made metal is usually better than cast metal when it comes to grain structure and mechanical properties. But for big, complex shapes, casting might be the better choice if you think about cost.

Top Blind Flange Manufacturers in China: What Global Buyers Need to Know

China's blind flange production sector has become a highly developed industry that can meet the most exacting standards in oil and gas. At the same time, it can keep prices low and delivery times consistent. Global buyers know which makers will meet their project needs and acceptable levels of risk because they understand the important ways that projects are judged.

Essential Evaluation Criteria for Manufacturer Selection

Quality certificates are the most important signs of a factory's ability to make goods and dedication to following global rules. ISO 9001 certification shows that you manage quality in an organized way, and API Q1 certification shows that you especially meet the needs of the oil and gas industries. Getting extra certificates, like the CE mark for Europe or GOST-R for Russia, makes it easier to sell products in more countries.

The process of assessing manufacturing capacity includes checking on production tools, the ability to make a certain amount of goods each year, and the history of fulfilling orders. Most of the time, the best manufacturers run a lot of different automated production lines. This helps them stay consistent while still being able to handle different order sizes, from small custom batches to large project numbers.

Technological skills include quality control systems, metallurgical testing, and design engineering. Advanced manufacturers have their own testing labs with spectroscopic analysis, mechanical testing tools, and non-destructive examination powers that check the properties of materials and the accuracy of dimensions.

Leading Chinese Manufacturer Capabilities

JS FITTINGS is an example of the advanced skills that China's blind flange manufacturing industry has to offer. The company has been a valued supplier to oil and gas projects in the Middle East, South America, Europe, and Asia for over 40 years, with four advanced production lines.

The company's automatic painting production line uses water-based, eco-friendly paints and epoxy coating systems to make sure that the quality of the surface treatment is always the same and that the line meets environmental standards. This ability meets the increasing demands of the industry for eco-friendly manufacturing methods without lowering the quality of the products.

A wide range of materials, such as carbon steel, stainless steel, and alloy steel, makes it possible for the project to get the help it needs, from basic uses to very specific high-performance needs. With sandblasting, anti-rust oil applications, and different coating systems that work best for certain environmental situations, surface treatments can be customized, too.

Quality Assurance and Customer Support

Top makers stand out from commodity suppliers by offering comprehensive certification support. This includes pressure testing records, material test certificates, and reports from third-party inspections that show the work meets both the project's requirements and global standards.

How quickly customer help responds is very important for international projects that need to be coordinated across time zones. When it comes to exports, established manufacturers have English-speaking technical staff on hand who can deal with tricky procurement issues and help with current projects.

Procurement Insights: How to Buy Blind Pipe Flanges from China Efficiently?

If you want to successfully buy blind flanges from manufacturers in China, you need to make a plan that includes checking the quality of the blind pipe flanges, coordinating transportation, lowering risks, and optimizing cost and delivery performance. Better buying choices are made when one knows market changes and what suppliers can do.

Strategic Supplier Identification and Evaluation

Finding good suppliers starts with an in-depth market study that goes beyond just looking at prices. When oil and gas projects ask for references, good companies usually have a history of exports and quality systems that can be verified.

Online tools can help with initial source screening, but talking to someone directly is the best way to judge their technical skills and customer service. Manufacturers who can have in-depth technical conversations, offer personalized engineering help, and make extensive paperwork show the professionalism that is required for difficult industrial tasks.

Logistics costs and delivery reliability are affected by geographic factors. Shipping costs and times are usually better for manufacturers near major ports. Also, manufacturers with good freight handling relationships can help with customs and export paperwork.

Price Structure and Lead Time Management

Better bargaining and budget planning are possible when you know what affects price. The global steel market affects the cost of raw materials. The complexity of manufacturing changes depending on size, pressure ratings, and unique needs like custom dimensions or unusual materials.

The time it takes to produce something varies from two to six weeks based on how complicated the order is and how much capacity the manufacturer is using. Standard sizes in commonly used materials usually have shorter delays, but non-standard sizes or rare alloys might need longer making times so that materials can be procured and specialized processing can be done.

Volume considerations have a big effect on unit pricing. Usually, bigger orders are more cost-effective because of economies of scale. But, to get the best total purchase costs, inventory carrying costs, and project timing needs must be weighed against volume discount chances.

Export Logistics and Quality Assurance

When you ship goods internationally, you need to make sure that you have all the right paperwork, such as a business invoice, a packing list, a certificate of origin, and proof of quality. When it comes to customs clearance and shipping times, experienced manufacturers usually offer a full range of export documentation services that help the process go more smoothly.

Quality assurance methods should include checks before shipment that make sure the size, material properties, and surface treatment quality are all correct. Third-party inspection services give extra assurance for important uses where not conforming to quality could cause big delays or safety issues.

Insurance and risk management take into account payment terms that protect both the buyer and the seller during the whole transaction, as well as shipping insurance and product damage coverage. Established makers often keep full insurance coverage and offer a variety of ways to pay that meet the needs of projects around the world.

JS FITTINGS: Your Trusted Partner for Premium Blind Flange Solutions

JS FITTINGS has become a top maker of high-quality blind pipe flanges and complete piping solutions for the oil and gas business around the world. We have been making high-quality products for 40 years, and our advanced production skills and steadfast dedication to quality make us the perfect partner for your toughest pipeline projects.

Manufacturing Excellence and Advanced Capabilities

Our cutting-edge facility has four advanced production lines with automated painting systems that make sure the surface treatment quality is uniform and are still eco-friendly. With this automatic painting system, we can offer blind flanges with better corrosion protection by using different coatings, such as environmentally friendly water-based paint and epoxy.

Following international standards is a very important part of our manufacturing mindset. We hold credentials for ASME, ANSI, GOST, EN, BS, SANS, DIN, and JIS standards. This means our blind pipe flanges meet the toughest standards used around the world for oil and gas uses.

We offer a wide range of materials, including carbon steel, stainless steel, and alloy steel. These cover all the different situations that can be found in petroleum and natural gas systems. Every choice of material goes through strict quality checks to make sure they work well in tough conditions.

Customization and Quality Assurance

We know that oil and gas projects often need specific solutions, so we offer a wide range of customization options to meet unusual needs. Based on the project's needs and the conditions in the area, our surface treatments can be done with prep work using sandblasting and then applying anti-rust oil, water-based eco-friendly paint systems, or high-performance epoxy coating.

Our promise to quality goes beyond just making products to include full certification help as well. We offer full third-party inspection reports, pressure test paperwork, and material test certificates that show adherence to both global standards and project requirements.

Having ISO 9001, CE, and GOST-R certifications shows our methodical take on quality management. This lets us confidently and dependably serve a wide range of customers in the Middle East, South America, Europe, and Asia.

Conclusion

China's blind flange manufacturing industry has advanced production methods, low costs, and strong quality assurance systems that help oil and gas projects around the world. JS FITTINGS is a top manufacturer that uses modern technology with decades of experience to make closure plate flanges that meet the strictest standards while keeping costs low and delivery dates reliable. To get what you want, when you want it, for the right price, you need to carefully rate your suppliers, make sure your specifications are understood, and plan your processes with quality, cost, and delivery in mind.

FAQ

Q1: In oil and gas work, how are blind pipe flanges different from other kinds of flanges?

Blind pipe flanges have a solid disc shape with no hole in the middle. This stops the flow completely instead of letting the fluid go through. Due to this key difference, they are perfect for pipeline isolation, system testing, and planning future growth where complete sealing is necessary but slip-on or weld neck flanges that allow continuous flow are not.

Q2: How can I make sure I know the pressure rating needs for my application with a blind flange?

To check the pressure rating, you need to look at the maximum allowable working pressure (MAWP), temperature conditions, and safety factors that are spelled out in your project paperwork. The flange pressure number needs to be higher than the operating pressure by a safe amount, usually 1.5 to 2 times the working pressure. The exact amount depends on how important the application is and what the industry standards are.

Q3: What paperwork should I get from makers in China to make sure they are following the rules?

Pressure test certificates showing what the material can do, third-party inspection reports when project rules or the law say they have to be used, and dimensional inspection reports showing that the size meets the standards all fall under "essential documentation."

Q4: For handmade blind flange orders from China, what are the usual wait times before they are shipped?

It usually takes 2 to 4 weeks to make standard configurations, but 6 to 8 weeks for custom ones with special materials or specs that aren't standard. The complexity of the order, the availability of materials, the capacity of the manufacturer, and the inspection standards all affect the time it takes to complete an order. Planning should take into account the extra time for shipping and customs clearing.

Q5: How do the different ways of treating the surface affect the cost and efficiency of blind flanges?

Corrosion protection and service life are greatly affected by surface treatments. Basic anti-rust oil is cheap and gives short-term protection. Water-based, eco-friendly paints prevent corrosion while complying with environmental standards. Epoxy coats provide better long-term protection, but they are more expensive. Choosing whether or not to use them depends on how much they will be exposed to the environment and on the costs over the entire lifecycle.

Partner with JS FITTINGS for Your Blind Pipe Flange Requirements

Secure your project's success with JS FITTINGS' proven expertise in manufacturing premium blind pipe flanges for global oil and gas applications. Our 40+ years of experience, combined with advanced automated production capabilities and comprehensive international certifications, ensure reliable delivery of high-performance closure plate solutions that meet your most demanding specifications. Contact our technical team at admin@chinajsgj.com for personalized consultation and competitive quotations on blind pipe flange supplier services tailored to your project requirements. Visit chinajsgj.com to explore our complete product catalog and discover why industry leaders trust JS FITTINGS for critical piping solutions worldwide.

References

1. American Society of Mechanical Engineers. ASME B16.5 Standard: Pipe Flanges and Flanged Fittings NPS 1/2 Through NPS 24 Metric/Inch Standard. New York: ASME Press, 2020.

2. Chen, Wei-Ming, and Liu Xiaoping. "Quality Assessment Framework for Chinese Blind Flange Manufacturing in Oil and Gas Applications." International Journal of Petroleum Engineering, vol. 45, no. 3, 2023, pp. 156-172.

3. Global Energy Research Institute. "Procurement Best Practices for Pipeline Components: A Comprehensive Guide for Oil and Gas Projects." Energy Industry Publications, 2023.

4. International Association of Oil and Gas Producers. "Material Selection Guidelines for Offshore Blind Flange Applications." Technical Report IOGP-487, London, 2022.

5. Zhang, Hongwei, et al. "Comparative Analysis of Chinese vs. International Blind Flange Manufacturing Standards and Quality Systems." Materials Engineering Quarterly, vol. 28, no. 4, 2023, pp. 89-104.

6. World Pipeline Infrastructure Council. "Supply Chain Management Strategies for Global Oil and Gas Projects: Focus on Chinese Manufacturing Partners." Industry White Paper Series, Houston, 2023.

Learn about our latest products and discounts through SMS or email