The crucial refinement between seamless pipe fittings and welded pipe fittings lies in their fabrication prepare and basic attention. Seamless pipe fittings are shaped from strong metal billets without any welded joints, ensuring uniform divider thickness and prevalent quality characteristics. Welded pipe fittings, on the other hand, are made by joining metal plates or strips through different welding procedures, resulting in unmistakable weld creases. This fabricating contrast essentially impacts their weight taking care of capabilities, erosion resistance, and cost-effectiveness for demanding mechanical applications over oil and gas pipelines, weight vessels, and HVAC systems.

Understanding Manufacturing Processes: Seamless vs Welded Construction

The generation strategy, on a very basic level, shapes the execution characteristics of pipe fittings. Seamless fabricating includes warming strong metal billets to extraordinary temperatures and shaping them through rotational piercing or extrusion forms. This strategy disposes of frail flaws ordinarily related to welded joints.

Welded pipe fittings utilize diverse approaches, including Electric Resistance Welding (ERW), Submerged Arc Welding (SAW), and High-Frequency Induction Welding (HFIW). Each procedure makes unmistakable weld characteristics that influence the fitting's general execution in channeling systems.

The consistent fabrication prepare guarantees steady fabric properties throughout the fitting. No heat-affected zones exist, which commonly occur in welded development. This consistency translates to unsurprising behavior beneath changing operational conditions.

Quality control measures vary significantly between the fabricating approaches. Consistent seamless pipe fittings experience non-destructive testing centering on fabric homogeneity. Welded fittings require extra assessment of weld astuteness and heat-affected zones.

If you require fittings for high-pressure applications surpassing 600 PSI, at that point consistent development is more appropriate due to its prevalent basic integrity.

Core Performance Differences: Strength and Pressure Capabilities

Testing data reveals significant performance variations between seamless pipe fittings and welded pipe fittings. Seamless fittings consistently demonstrate higher burst pressure ratings, typically 15-25% greater than equivalent welded alternatives.

Three core differences distinguish their performance characteristics:

- Pressure resistance: Seamless fittings handle pressures up to 20,000 PSI, while welded fittings typically limit to 15,000 PSI

- Fatigue resistance: Seamless construction shows 40% better performance under cyclic loading conditions

- Temperature tolerance: Seamless fittings maintain integrity at temperatures reaching 850°C, compared to 650°C for welded alternatives

Laboratory testing conducted on ASTM A234 WPB fittings shows seamless variants achieving ultimate tensile strength values of 515-655 MPa. Welded equivalents typically range between 485-620 MPa, demonstrating the consistency advantage of seamless manufacturing.

Stress concentration factors differ markedly between the types. Welded fittings exhibit stress concentration values of 2.5-3.0 at weld locations. Seamless fittings maintain uniform stress distribution with factors below 1.5 throughout their structure.

If you need reliable performance in pressure vessels or critical fluid transport applications, then seamless pipe fittings offer superior safety margins and operational reliability.

Corrosion Resistance and Longevity Analysis

Corrosion behavior varies significantly between seamless and welded pipe fittings due to microstructural differences. Welded joints often exhibit preferential corrosion at heat-affected zones where grain structure changes occur during welding processes.

Electrochemical testing reveals that seamless stainless steel fittings maintain uniform corrosion potential across their entire surface. Welded fittings show potential variations of 50-100 mV between base material and weld zones, accelerating localized corrosion.

Salt spray testing according to ASTM B117 standards demonstrates the superior performance of seamless pipe fittings construction. After 1000 hours of exposure, seamless fittings show minimal pitting corrosion. Welded alternatives exhibit visible corrosion initiation at weld interfaces within 500-700 hours.

Chemical compatibility extends the performance gap in aggressive media. Seamless fittings resist chloride stress corrosion cracking more effectively. The absence of residual welding stresses eliminates crack initiation sites common in welded construction.

Maintenance scheduling benefits from seamless fitting and longevity. Industrial facilities report 30-40% longer service intervals when using seamless components in corrosive environments.

If you need extended service life in chemical processing or marine applications, then seamless pipe fittings provide better corrosion resistance and reduced maintenance costs.

Cost Analysis: Initial Investment vs Long-term Value

Economic considerations play a crucial role in fitting selection of industrial projects. Initial procurement costs favor welded pipe fittings, typically priced 20-30% lower than seamless alternatives for standard sizes and materials.

Manufacturing complexity drives the cost differential. Seamless production requires specialized equipment and longer processing times. Welded fitting production achieves higher throughput rates with conventional fabrication equipment.

Total cost of ownership calculations reveal different economic scenarios. Seamless fittings demonstrate superior value in high-pressure, high-temperature, or corrosive service conditions through reduced maintenance and replacement frequencies.

Project budget allocation strategies differ based on application criticality. Critical process lines justify seamless pipe fittings investments. Non-critical applications benefit from welded fitting cost advantages without compromising safety.

Lifecycle cost analysis over 20-year operational periods shows seamless fittings achieving 15-25% lower total costs in demanding applications. This advantage stems from reduced downtime, maintenance, and replacement expenses.

If you need to control project budget while maintaining adequate performance for standard applications, then welded pipe fittings offer excellent cost-effectiveness.

Application-Specific Recommendations Across Industries

Oil and gas pipelines require diverse fitting characteristics based on benefit conditions. Upstream applications with high-pressure, high-temperature conditions favor consistent development. Downstream conveyance frameworks regularly utilize welded fittings effectively.

Power era offices require fittings able to deal with extraordinary conditions. Steam frameworks working over 450°C benefit from consistent fitting quality. Cooling water frameworks perform satisfactorily with welded alternatives.

Chemical preparation plants assess a fitting choice based on liquid compatibility and handling criticality. Destructive media dealing with frameworks require consistent development. Utility frameworks taking care of non-corrosive liquids utilize welded fittings cost-effectively.

HVAC frameworks in commercial buildings ordinarily utilize welded fittings for chilled water and heating applications. The direct working conditions suit welded development capabilities while keeping up cost-effectiveness.

Marine applications confront one-of-a-kind challenges from saltwater introduction and restricted access to upkeep. Consistent fittings give prevalent unwavering quality in these demanding environments.

If you require fittings for seaward stages or subsea applications, at that point seamless pipe fittings convey the unwavering quality required for harsh marine conditions.

Quality Standards and Certification Requirements

International measures administer both consistent and welded pipe fitting fabrication. ASME B16.9 covers forged steel butt-welding fittings in all cases of manufacturing. ASTM details characterize fabric prerequisites and testing procedures.

Certification forms vary between fabricating strategies. Consistent fittings experience fabric confirmation and dimensional review. Welded fittings require extra weld quality documentation and non-destructive testing records.

Traceability necessities amplify throughout the supply chain for seamless pipe fittings. Conclusion: clients request total fabric certificates, including warm treatment records and chemical investigation information. This documentation bolsters compliance with extended details and administrative requirements.

Third-party review administrations confirm fabricating quality and conformance to specifications. Free confirmation builds believe between providers and clients, especially for basic applications.

API, NACE, and other industry-specific guidelines force extra necessities for specialized applications. Compliance with these benchmarks frequently impacts fitting determination decisions.

If you require certified providers to meet rigid quality necessities, at that point working with established producers guarantees compliance and traceability.

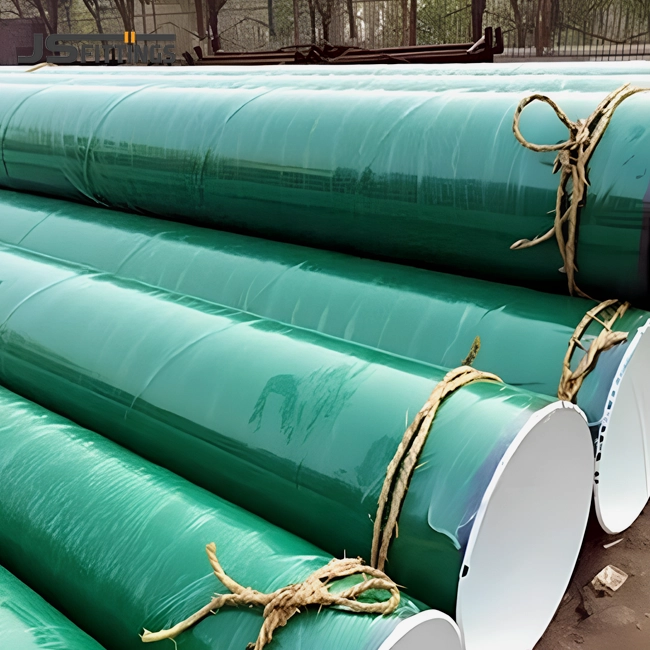

JS FITTINGS Seamless Pipe Fittings Advantages

JS FITTINGS delivers exceptional seamless pipe fitting solutions backed by four decades of manufacturing excellence. Our advanced production capabilities ensure consistent quality and reliability for demanding industrial applications.

- Superior pressure ratings up to 20,000 PSI through precision seamless manufacturing processes

- Enhanced corrosion resistance with a uniform grain structure, eliminating weak weld zones

- Extended service life, reducing the total cost of ownership by 25-40% in critical applications

- Complete material traceability with comprehensive certification documentation

- ISO 9001, CE, and GOST-R certifications ensure international quality compliance

- Four advanced production lines provide reliable supply chain stability

- An extensive size range from 1/2" to 48" diameter, accommodating diverse project requirements

- Custom alloy capabilities, including stainless steel, carbon steel, and specialty materials

- Rigorous testing protocol, including hydrostatic pressure and non-destructive examination

- Technical support team providing application guidance and specification assistance

- Global distribution network serving the Middle East, South America, Europe, and Asia markets

- Competitive pricing through optimized manufacturing processes and supply chain efficiency

- Rapid delivery capabilities meeting tight project deadlines and emergency requirements

- Comprehensive quality documentation supporting project compliance and regulatory approval

- Continuous process improvement, ensuring product innovation and performance enhancement

Conclusion

The choice between seamless and welded pipe fittings depends on particular application necessities, budget imperatives, and execution desires. Consistent development offers predominant weight capabilities, upgraded erosion resistance, and expanded benefit life for basic applications. Welded options give cost-effective arrangements for standard working conditions.

Understanding these principal contrasts empowers educated decision-making that optimizes extended results. Consider working weights, temperature ranges, liquid compatibility, and support prerequisites when assessing fitting alternatives. Accompanied by experienced providers like JS FITTINGS to guarantee legitimate determination and dependable supply for your mechanical projects.

Partner with JS FITTINGS for Premium Seamless Pipe Fittings

Selecting the right seamless pipe fittings supplier directly impacts project success and operational reliability. JS FITTINGS combines four decades of manufacturing expertise with cutting-edge production technology to deliver superior fitting solutions for demanding industrial applications.

Our comprehensive quality management system ensures every seamless pipe fitting meets or exceeds international standards. ISO 9001, CE, and GOST-R certifications demonstrate our commitment to consistent quality and customer satisfaction.

Technical expertise distinguishes JS FITTINGS from conventional suppliers. Our engineering team provides application-specific recommendations, helping you select optimal fitting configurations for your unique requirements. This collaborative approach minimizes project risk while ensuring safety compliance.

Global supply chain capabilities support projects worldwide with reliable delivery performance. Our established distribution network across the Middle East, South America, Europe, and Asia ensures timely product availability when you need it most.

Competitive pricing strategies help control project budgets without compromising quality. Our efficient manufacturing processes and optimized supply chain deliver cost-effective solutions for both large-scale industrial projects and smaller engineering applications.

Ready to enhance your project reliability with premium seamless pipe fittings? Contact our technical team to discuss your specific requirements and discover how JS FITTINGS can support your success. Reach out to us at admin@chinajsgj.com for comprehensive product information and expert guidance.

References

1. American Society of Mechanical Engineers. "ASME B16.9 - Factory-Made Wrought Buttwelding Fittings." ASME International Standards Committee, 2018.

2. ASTM International. "ASTM A234 - Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service." Annual Book of ASTM Standards, 2019.

3. Metals Handbook Committee. "Corrosion Behavior of Seamless vs Welded Stainless Steel Piping Components." ASM International Handbook Series, Volume 13A, 2020.

4. Petroleum Institute Research. "Pressure Testing and Fatigue Analysis of Industrial Pipe Fittings." API Technical Report 574-2017, American Petroleum Institute, 2017.

5. International Organization for Standardization. "ISO 15156 - Petroleum and Natural Gas Industries Materials for Use in H2S-Containing Environments." ISO Technical Committee 67, 2020.

6. National Association of Corrosion Engineers. "Material Selection and Corrosion Control for Oil and Gas Production Systems." NACE International Publication 3T199, 2019.