Black mild steel pipes are strong, not expensive, and useful in many ways. They are a great buy for building projects because of this. There is only 0.05% to 0.25% carbon in some of these carbon steel pipes. They are a cheap way to hold things up. They can be used to build the bases of factories or to install plumbing in homes. Mild steel pipe systems made of black steel work well and follow strict safety rules without affecting project schedules or costs. They are easy to bend and join, which is why.

A Quick Look at Mild Steel Black Pipes

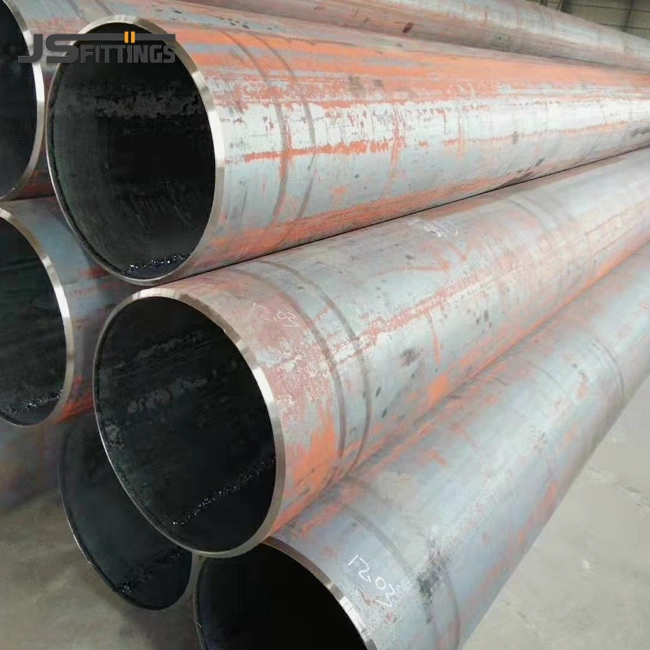

One of the most important building materials today is black mild steel pipes. People trust them because they've been used for decades in many places and have always worked well. As it is being made, hot-rolled steel slowly cools down. To keep it safe, it doesn't have any extra cover. This is what makes the pipes look dark. At 240 to 400 MPa, its yield strength makes it very strong. It can be used for both load-bearing and non-structural tasks.

Most of the time, these pipes are made with iron that has between 0.05% and 0.25% carbon mixed in. This helps you work with and weld them better. The rules set by ASTM A53, API 5L, or IS 1239 are used by most laws. This makes sure the quality and size are always the same. The nominal bores on these pipes are between 15 mm and 600 mm. They can be used for a lot of different things, from small water systems at home to big ones in factories.

This is what a project manager should know about black steel pipes in order to make better choices about what to use. Since all the walls are the same thickness, engineers can easily guess what the mechanical properties will be. It's also easy to connect to pipes and fittings that are already in place because the sizes are standard.

Why are mild steel pipes that are black better for building?

When it comes to building, black steel pipes are always chosen because they are cheap and work well. This is even clearer when you think about how long the project will last and how much it will cost to own.

For building projects, we need these pipes because of these things:

- Black steel pipes can handle temperatures as low as -40°C and as high as 400°C. In other words, they can be used for fast jobs and ones that need to be done outside. To make them last, they are strong and won't break on their own. Also, even when things are pushed together very hard, their structure stays put. Based on the pipe schedule and diameter, the pressure at work can be more than 150 psi.

- In most building projects, these pipes do the same job as stainless steel ones, but they cost 40–60% more. This is a great deal. Because they are cheaper and easier to weld, they can be put up faster and for less money. The contractors can then work faster on other parts of the project.

- It's possible to pull black steel pipes apart and still have them hold a lot of weight without being too heavy. Most of the time, this strength is between 400 and 500 MPa. When you build something, you should keep the strength while lowering the dead loads. This house is useful when those things happen.

- Very machinable: This means it is easy to thread, cut, and shape. It works well with most tools. This is possible as long as the welding properties don't change. The joints can be as strong as the pipe body needs to be.

These benefits make projects safer and help people remember when they need to do things. The people who put black mild steel pipe in these things never have to guess how to do it; they always do it the same way. Engineers and other project workers are also sure of the track record of these materials.

Seeing how black mild steel pipes stack up against other materials

For a project to go well, you need to choose the right materials. That's why you should know how black steel pipes stack up against other options. It is easy to see which benefits are important for various project types and how to choose what to buy after comparing them.

You can save 15 to 25 per cent per linear foot right away if you compare black mild steel pipe to black steel pipes to galvanised steel pipes. Pipes that are galvanised have a zinc coating that makes them less likely to rust. On the other hand, black steel pipes work better in places where corrosion isn't a problem or where coatings can be added after installation to protect them. Iron that hasn't been coated is easier to weld than iron that has been coated with zinc, which can get in the way of the process. This makes the joints stronger.

There is a price difference between black steel pipes and stainless steel pipes. Stainless steel pipes cost 300 to 400% more. Due to the large price difference, black steel pipes are better for projects that need to stay within a budget. If the pipes are coated properly, they can be made resistant to corrosion, and the project can be replaced often over its lifetime. Black steel usually has higher tensile strengths than other steels, but they still work pretty much the same.

Metals might not rust as quickly with plastic and composite materials, but they aren't strong enough to hold weight. PVC pipes can catch fire, but steel pipes don't, and they keep their shape when the temperature changes. Steel is also better for the environment than plastic because it can be reused another time.

What You Can Do With Mild Steel Pipes That Are Black?

Because they are strong, cheap, and easy to work with, black steel pipes can be used in many building projects. Builders and engineers can find the best ones for their projects if they know about these uses.

Putting things together is one very common use. In warehouses and other industrial buildings, the pipes are often used as beams, columns, and supports. Engineers can design structures with confidence because they know how they will hold weight. Because the structures are easy to make, they can be built faster. Frames made of black steel pipes are used in many large factories because they can hold heavy loads and stop forces that move things around.

Steel pipes that are black are often used for plumbing and water systems in businesses and factories. In factories, steel pipe systems work better because they can handle high pressure and last longer. For homes, most of the time, other materials work better. Because these pipes can handle both hot and cold water, they are great for building systems that need to heat, cool, and move process water around.

As a safety measure, fire sprinkler systems often use black mild steel pipe black steel pipes that don't catch fire. This helps keep the building together in an emergency. The system will work reliably because it is built to last when it's needed the most. It's possible to guess how the material will react to fire.

In order to move oil and gas, black steel pipes are used because they can handle high pressures and chemicals well. It is important that the parts of these systems work well and are safe, because they often have to work in dirty or dangerous places.

Getting Black Mild Steel Pipe to Work Better

Remember to follow safety rules and put black steel pipe systems together the right way to get the most out of them. These things really change how long something lasts and how well it works in general.

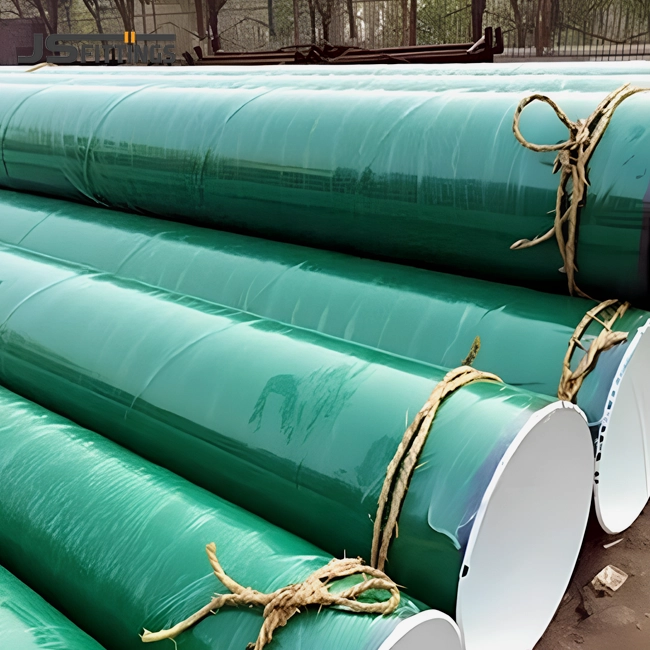

Protecting pipes from corrosion is very important if you want them to last longer, especially if they will be exposed to chemicals or water. You can protect things with epoxy systems, which are very resistant to chemicals and can last up to 15 to 20 years in harsh environments. After something is made, it can be galvanised to protect it. This process needs to be carefully thought out, though, because it can change the size of the metal and mess up threaded connections.

Using the right installation methods will ensure that the system works at its best for as long as it lasts. When threading, the right thread compound should be used to keep the threads clean and sharp, stop leaks, and ensure the joints are strong enough. There are rules about how to weld that include how to pre-heat and treat the pipe after the weld, depending on the thickness of the wall or the temperature of the area.

The space between supports and the way black mild steel pipes are routed help keep stress levels from building up too much, which could cause the structure to fail early. Thermal expansion accommodation is very important for systems that are subject to changes in temperature. Stress-related problems can be avoided by putting expansion joints in the right places and designing support structures in the right way.

How to Choose the Best Company to Get Black Mild Steel Pipes?

Which supplier you choose has a direct impact on the success of a project through the materials they provide, how reliable their delivery is, and how well they can support you after the project is finished. A lot of different things need to be carefully thought through when looking at possible suppliers, not just prices.

Quality certifications give people the peace of mind they need about the materials used and how consistently they are made. Suppliers who have ISO 9001 certification show that they care about quality management systems. Other credentials, such as API, ASTM, or regional standards, prove that they know how to use those systems. It is important to have material test certificates and allow a third party to check that the project requirements and government rules are followed.

“Manufacturing capacity and abilities affect delivery times and the ability to meet the unique needs of each project. Suppliers who have a lot of different sizes and production lines can meet the needs of many projects and keep delivery dates steady. New tools and systems for controlling the manufacturing process help make sure that black mild steel pipe measurements are correct and that mechanical properties stay the same.

Technical support and engineering help are very helpful for projects that have complicated applications or strange operating conditions. Application engineering services, help with choosing materials, and help with installation are all extras that suppliers offer that make their services more valuable than just selling products.

JS FITTINGS: Trusted Black Mild Steel Pipe Solutions

JS FITTINGS has established itself as a reliable partner for construction professionals seeking high-quality steel piping solutions backed by decades of manufacturing expertise. Our comprehensive approach to black steel pipe manufacturing combines advanced production capabilities with rigorous quality control systems to ensure consistent product performance across all applications.

Our four advanced production lines enable us to manufacture pipes in various sizes and specifications while maintaining strict adherence to international standards, including ASTM, API, and DIN requirements. The ISO 9001, CE, and GOST-R certifications demonstrate our commitment to quality management and regulatory compliance, providing customers with confidence in material specifications and performance characteristics.

The technical expertise developed over 40 years of manufacturing experience translates into superior product quality and reliable customer support. Our engineering team works closely with contractors and project managers to ensure black mild steel pipe material selections align with specific application requirements, while our quality assurance protocols guarantee dimensional accuracy and mechanical property compliance.

Global supply capabilities enable us to support projects across multiple geographic regions, with established distribution networks ensuring reliable delivery schedules. The combination of competitive pricing and proven performance makes our black steel pipe products an excellent choice for contractors seeking to optimise project costs while maintaining quality standards.

Conclusion

Black mild steel pipes are useful for building because they are inexpensive, work well, and can be used for many tasks. These pipes are what architects and builders should use if they want to make things that will last a long time. They're not expensive, strong, and easy to use. Safety first: Black steel pipe systems can last for many years if they are put in the right way. They make sure projects don't go over budget, are safe, and follow the rules.

FAQ

Q1: What is the difference between black steel pipe and galvanised steel pipe?

A: The primary difference lies in the protective coating. Black steel pipes have no protective coating and display the natural dark colour of steel, while galvanised pipes feature a zinc coating that provides corrosion resistance. Black steel pipes cost less and offer superior weldability, making them ideal for applications where corrosion protection can be achieved through other means or where welded joints are critical.

Q2: How long do black steel pipes last in construction applications?

A: Service life depends significantly on environmental conditions and protective measures. In indoor applications with minimal moisture exposure, properly installed black steel pipes can last 40-70 years. Outdoor applications typically require protective coatings to achieve similar lifespans, while aggressive environments may need additional protection or more frequent replacement cycles.

Q3: Can black steel pipes be used for potable water systems?

A: While black steel pipes can technically carry potable water, they are not recommended for drinking water applications due to potential corrosion and taste issues. These pipes excel in fire protection, heating systems, and industrial applications where water quality concerns are less critical. For potable water, consider galvanised or plastic alternatives designed specifically for drinking water systems.

Partner with JS FITTINGS for Your Black Mild Steel Pipe Requirements

Successful construction projects demand reliable materials and trusted suppliers who understand the critical importance of quality and timely delivery. As an experienced black mild steel pipe manufacturer, JS FITTINGS combines four decades of industry expertise with modern production capabilities to deliver superior piping solutions that meet the demanding requirements of today's construction environment.

Our commitment to excellence extends beyond manufacturing to include comprehensive customer support, technical guidance, and flexible delivery options that accommodate project schedules. The extensive certifications and proven track record across international markets provide the assurance needed for critical infrastructure projects where material reliability cannot be compromised.

Ready to discuss your black mild steel pipe requirements with our technical team? We invite you to contact us at admin@chinajsgj.com to explore how our manufacturing capabilities and industry expertise can support your upcoming projects. Visit chinajsgj.com for detailed product specifications and technical resources, or speak with our application engineers about optimising material selections for your specific construction requirements.

References

1. American Society for Testing and Materials. "Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless." ASTM International.

2. Steel Construction Institute. "Structural Steel Design Guide: Properties and Applications of Carbon Steel Pipes in Building Construction." London: SCI Publications.

3. National Association of Corrosion Engineers. "Corrosion Prevention and Protection Methods for Carbon Steel Piping Systems." NACE International Technical Publication.

4. International Organization for Standardization. "Steel Pipes for Mechanical and General Engineering Purposes: Technical Delivery Conditions." ISO Standards Catalogue.

5. American Welding Society. "Welding Procedures and Techniques for Carbon Steel Pipe Systems in Construction Applications." AWS Technical Documents.

6. Construction Industry Research Association. "Material Selection Guidelines for Commercial and Industrial Piping Systems: Cost-Benefit Analysis of Steel Alternatives." CIRA Technical Report Series.