In industrial piping systems, a weld neck flange is one of the most reliable and structurally strong ways to connect pipes. This unique flange has a long, tapered hub that joins seamlessly with pipe walls through butt welding. This makes a continuous metal path that evenly distributes stress throughout the joint. Because it doesn't have any sharp edges or stress concentration points like other flange types do, it's the best choice for high-pressure, high-temperature situations where safety and performance can't be compromised.

Understanding Weld Neck Flanges: What They Are and How They Work

What is a Weld Neck Flange?

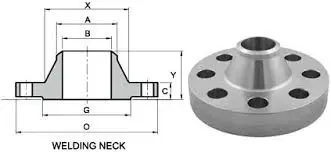

The main feature that sets a weld neck flange apart from other types of flanges is its long neck section that gradually changes from the pipe diameter to the flange face diameter. This tapered hub usually goes out one pipe wall thickness past the flange face, making a smooth bore transition that matches the connecting pipe's internal diameter.

The raised face or flat face sealing surface, the precisely machined bolt holes arranged in standard patterns, and the unique neck that provides exceptional reinforcement at the pipe-to-flange junction are some of the most important structural features. The continuous metal structure gets rid of any possible leak paths or weak spots that could form in mechanical connections.

How does a Weld Neck Flange work?

Making a strong, long-lasting connection by buttwelding the flange neck directly to the pipe end is the main idea behind the process. The flange material and the pipe material are fused during the welding process, turning them into a single, continuous piece. The tapered neck design makes sure that stress loads move slowly from the pipe to the flange body. This keeps stress from building up and causing failure.

Pressure forces and thermal expansion stresses are spread out evenly across the welded joint, through the flange body, and to the bolted connection while it is in use. This way of distributing stress makes it much better for the joint to handle repeated loads, sudden changes in pressure, and changes in temperature without getting fatigue cracks or seal degradation.

Useful Places for Applications

Weld neck flanges are often used in critical applications in industries that need the highest level of reliability. These flanges are used a lot in high-pressure pipeline systems, wellhead connections, and refinery process equipment in oil and gas processing plants. Power plants depend on them for things like steam lines, feedwater systems, and connections to turbines. If they fail, terrible things could happen.

Weld neck flanges that are properly specified offer better corrosion resistance and structural integrity in petrochemical processing environments. Welded connections are especially useful on offshore platforms because they are reliable in harsh marine environments where maintenance access is limited, and system uptime is very important.

Standards for designing weld neck flanges and their sizes

A Look at the Common Design Standards

Every part of the design of a weld neck flange has to follow international standards to make sure that it works with everything and is safe. As the main standard in North American markets, ASME B16.5 lists the size requirements, pressure ratings, and material requirements for flanges with a diameter of up to 24 inches. API standards add to ASME specifications by adding more requirements for use in the oil and gas industry.

In Europe, markets usually follow DIN and EN standards. ISO standards, on the other hand, make sure that all countries follow the same rules. These standards cover important factors like hub sizes, bolt hole tolerances, face finishes, and marking requirements. Following the right standards makes sure that the system works properly with parts from different manufacturers and that the system stays intact.

Chart of Weld Neck Flange Sizes

Understanding the dimensions is important for choosing the right flange and designing the right system. There are different outside diameters for each pressure class. For example, Class 150 flanges have smaller bolt circles and overall dimensions than Class 1500 flanges that have the same nominal pipe size. To handle higher stress loads, the hub's length and thickness get bigger as the pressure rating goes up.

Standardized patterns for bolts show that the number and size of bolts go up as the flange size and pressure rating go up. Face dimensions, such as the raised face height and diameter, must stay in a certain relationship to make sure the gasket seals properly and loads are spread evenly across the joint.

Ratings for Pressure and Temperature

Pressure class ratings tell you the highest pressure that different materials can handle at certain temperatures. For carbon steel applications, Class 150 flanges can usually handle 285 psi at room temperature. Class 2500 flanges, on the other hand, can handle pressures higher than 6000 psi in certain situations.

Temperature has a big effect on the maximum pressure that can be used. As operating temperatures rise, limiting factors are used. Knowing these connections helps engineers choose the right flanges that keep enough safety margins throughout the expected operating envelope without making the project more expensive than it needs to be.

What materials affect the performance of a weld neck flange

Material choice has a direct effect on how well flanges work, how long they last, and how cost-effective they are in a wide range of industrial settings. Some of the things that affect the choice of material are the operating pressure, temperature, the corrosive environment, and the cost.

Common Details About Materials

Because they are easy to find and have a great strength-to-cost ratio, carbon steel grades like ASTM A105 are used for most general-purpose tasks. These materials work great in mildly acidic or basic environments, so they can be used in water systems, compressed air systems, and many other hydrocarbon-based situations.

304, 316, and duplex alloys are all types of stainless steel that are very good at resisting corrosion and are used in chemical processing, food service, and marine applications. The chromium and nickel content make a passive oxide layer that protects against different corrosive media. However, choosing the right grade is still important for certain environments.

Alloy steels, like Chrome-Moly grades, are used in high-temperature processes like making electricity and processing petrochemicals. Even at high temperatures, these materials stay strong because they don't creep or get thermally worn down, which would happen with carbon steel.

Corrosion Resistance and How Long Something Will Last

In many situations, environmental compatibility is a more important factor than basic mechanical properties when it comes to choosing a material. Careful choice of stainless steel grade is needed in chloride environments to avoid stress corrosion cracking. On the other hand, hydrogen service may need special heat treatment or material limits to avoid hydrogen embrittlement.

Coatings and treatments on the surface of materials improve their performance in harsh environments. Hot-dip galvanizing is a great way to protect carbon steel flanges from the weather, and certain coatings can make them more resistant to chemicals than the base material itself.

Cast vs. Forged Neck Flanges That Weld

The manufacturing process has a big effect on the reliability and mechanical properties. Forged flanges have better mechanical properties and grain structure because they are hot worked, which smooths out the metal structure and gets rid of any internal holes. When flanges are made using this method, they are stronger, less likely to break when hit, and their properties are easier to predict.

Cast flanges are cheaper than forged ones when the size or type of material makes forging impractical. Products made with modern casting techniques are reliable, but they still need to be carefully inspected for any internal flaws that might affect their performance.

Tips on How to Weld and Check Weld Neck Flanges

A Look at the Welding Process

Installing a weld neck flange correctly depends on using the right welding technique and following the right steps. Gas tungsten arc welding (GTAW/TIG) gives you great control over root pass installation, making sure that the roots go all the way through and that the inside surfaces are smooth so that the flow characteristics stay the same.

Shielded metal arc welding (SMAW) and gas metal arc welding (GMAW/MIG) can quickly make fill and cap passes while keeping the mechanical properties needed. Preheating needs, interpass temperatures, and post-weld heat treatment must all be spelled out in the welding procedure specifications based on the material specifications and service conditions.

Step-by-Step Guide to Welding

The right way to get ready starts with cutting and beveling the pipe correctly so that it fits the shape of the flange neck. To avoid internal misalignment that could cause turbulence and erosion points in service, fit-up needs to be perfectly aligned. Tack welding keeps the pieces in place while they are being welded and lets them expand when they get hot.

The welding process goes from the root pass to the fill passes and finally to the final cap pass. After each pass, the weld needs to be properly cleaned and inspected. For some materials and service conditions, it may be necessary to do a post-weld heat treatment to get rid of any residual stresses and improve the mechanical properties.

How to Check Neck and Flange Welds?

Quality control starts with a visual inspection to find flaws on the surface, make sure the profiles are correct, and make sure the product looks good. Liquid penetrant testing finds flaws that break the surface that you might not be able to see with the naked eye. Magnetic particle testing, on the other hand, finds flaws close to the surface of ferromagnetic materials.

Radiographic and ultrasonic testing can be used for volumetric inspection to find problems inside the material, like holes, inclusions, or a lack of fusion. These non-destructive testing methods make sure that the integrity of the weld meets code requirements and service expectations without putting the joint at risk.

To help you choose the right flange, let's look at some other types.

To find the best flange for your needs, you should look at how much they cost. Different types of flanges are good for different jobs and tasks because they have different strengths.

In this article, Slip-On Flange and Weld Neck Flange are put side by side.

Since weld neck flanges are made from a single piece of metal, the stress changes slowly. They are stronger and less likely to break than slip-on flanges because of this. At first, it costs more, but this structural benefit makes up for it when there is a lot of stress, loading that changes over time, or an important service that would fail badly.

When slip-on flanges are used for low-pressure jobs that need the extra strength of a weld neck, there is less waste. They also use less stuff, which saves money. The amount of pressure needed, how simple it is to set up, and the long-term cost are some of the things that people look at when choosing one.

What's the difference between the Lap Joint Flange, the Weld Neck Flange, and the Blind Flange?

They are not the same. Blind flanges that are used for pressure testing are different from those that will be used for future connections. They're not at all the same. When you need to quickly put something together or take it apart many times, lap joint flanges come in handy. Also, they help you arrange things.

Lap joints let you change layouts more than weld necks, which don't move. They aren't as strong or waterproof as welded connections, but they can be shaped in different ways.

A neck flange that is forged or one that is cast and then stuck together?

Metal flanges that are forged are more likely to last longer and be stronger. This means they are better for important jobs, even though it costs more. The extra cost is worth it because the casting doesn't break under a lot of pressure, heat, or important service. The structure of the grains is also better.

Cast flanges can be used instead of forged ones sometimes because they don't need the extra things that forged materials have. Big flanges can't always be forged because of the tools that are used. They need to be cast instead. We still need to check the quality, though.

Read these tips and look at the prices before you buy.

There should be sections for how much the parts cost, how long they take to put together, how often they need to be checked, and how much it will cost to maintain them over time. Better materials or ways of making things usually cost more at first, but they pay for themselves over time because they work better, last longer, and need less maintenance.

When choosing a supplier, you should think about more than just price. If they say they can keep track of materials and deliver on time, that's a good sign. Only work with good suppliers, and you won't have to buy things that take longer than planned. The quality will also stay the same.

A question that lots of people have

What makes a weld neck flange unique?

On the other hand, weld neck flanges are different. They have a long hub with a tapered end that is butt-welded to the pipe. This plan makes a straight line of metal that spreads stress out evenly. This makes it stronger than flanges that screw on or slip on, so it's less likely to break. A weld doesn't leave weak spots or places where water can get through, as a mechanical connection does. It keeps the pieces together.

What is the best thing to use for my flange?

A: You need to think about the cost, the temperature, the pressure at which it will work, and the spot where it might rust. There is better steel than steel that rusts most of the time. Steel that doesn't rust works better with chemicals. Iron and steel that have been alloyed can handle high temperatures. Think about what will happen to something when chloride, hydrogen, and temperature changes happen before you buy it.

When there is a lot of heat and pressure, is it safe to use weld neck flanges?

A: Weld neck flanges can work well in high-temperature and high-pressure situations as long as they are installed and specified correctly. Because they are permanently joined, they can count on each other when things get tough. This way, the stress is spread out better. As long as you choose the right material, pressure class rating, and installation steps, the system will be safe.

Conclusion

When dependability, strength, and not leaking are most important in an industrial setting, weld neck flanges are the best choice. It is important for high-pressure pipe systems that they have these parts because they can handle more stress, are permanently joined, and have been used in tough situations before. You can make decisions that save money and improve performance by knowing the design principles, materials that are available, and installation requirements. It is worth the money to buy good weld neck flanges because they last longer, need less maintenance, and make operations safer. This keeps people and equipment safe throughout the lifecycle of the system.

Partner with JS FITTINGS for Premium Weld Neck Flange Solutions

When your project demands exceptional quality and reliability, JS FITTINGS delivers the weld neck flange expertise that industrial leaders trust. Our automated painting production lines ensure consistent surface finishes that enhance corrosion resistance and extend service life beyond industry standards. Every flange manufactured in our facilities complies with international standards, including ASME, API, DIN, and ISO specifications, providing the confidence that comes with proven compatibility and safety.

Our diverse material options encompass carbon steel, stainless steel, and specialized alloys to meet your specific application requirements. Whether you need standard configurations or customization for special requirements, our engineering team collaborates with you to develop solutions that optimize performance while controlling costs. Comprehensive certification support includes material test certificates, quality documentation, and third-party inspection services that satisfy the most stringent project requirements.

With over 40 years of manufacturing excellence, JS FITTINGS has earned the trust of clients across the Middle East, South America, Europe, and Asia through consistent quality and reliable delivery. Our weld neck flange manufacturer capabilities include advanced production lines that maintain tight tolerances and superior mechanical properties. Contact us at admin@chinajsgj.com to discuss your specific requirements and discover how our expertise can contribute to your project success.

References

1. American Society of Mechanical Engineers. "ASME B16.5 - Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard." ASME International, 2020.

2. American Petroleum Institute. "API Specification 6A - Specification for Wellhead and Christmas Tree Equipment." 21st Edition, API Publishing Services, 2019.

3. ASTM International. "ASTM A105/A105M - Standard Specification for Carbon Steel Forgings for Piping Applications." ASTM International Standards, 2019.

4. Becht Engineering Company. "Stress Analysis of Piping Systems: Flange Design and Analysis Methods." Journal of Pressure Vessel Technology, 2018.

5. Mohitpour, M., Golshan, H., and Murray, A. "Pipeline Design & Construction: A Practical Approach, Third Edition." American Society of Civil Engineers Press, 2017.

6. Nayyar, Mohinder L. "Piping Handbook, Eighth Edition." McGraw-Hill Professional Engineering Series, 2019.

_1757576028658.webp)